Chemical Refining Gold

Chemical Refining of Gold: Precision and Purity

Gold refining is an intricate process that transforms raw, impure gold into a refined, high-purity form. This article explores the various chemical methods used in the gold refining process, focusing on how these techniques ensure the highest levels of purity. With advancements in technology, FRT Machinery has developed innovative solutions that enhance the efficiency and effectiveness of gold refining. Here’s a closer look at the chemical processes involved.

Leaching: The Foundation of Chemical Refining Gold

Leaching is a critical first step in the chemical refining of gold, where the metal is dissolved from its ore using a leaching agent. Typically, cyanide is used for this purpose due to its ability to dissolve gold efficiently. At FRT Machinery, we employ advanced leaching systems designed to maximize gold extraction while minimizing environmental impact. Our systems ensure that the leaching process operates under optimal conditions, enhancing both the recovery rate and the purity of the gold produced.

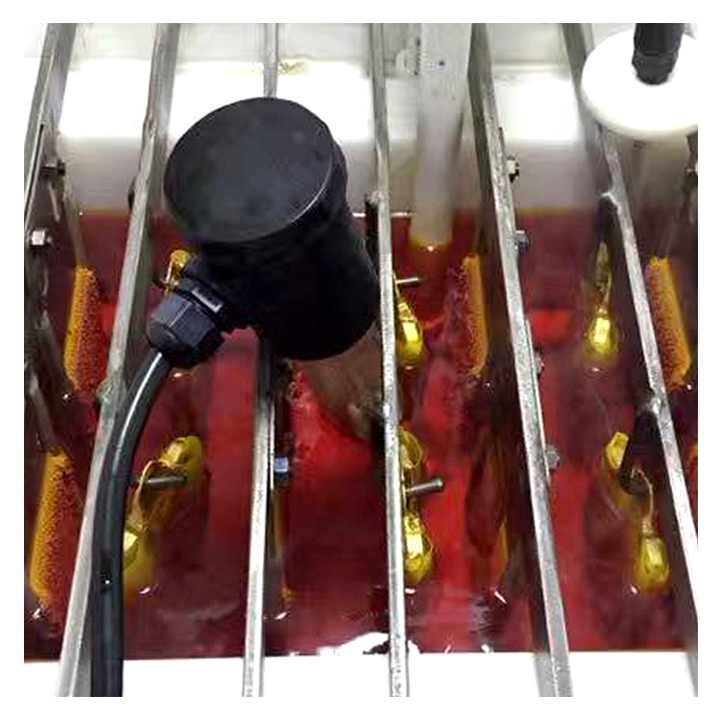

Electrowinning: Enhancing the Process of Chemical Refining Gold

Once gold has been leached out of the ore, it must be recovered from the solution. Electrowinning is one such method employed during the chemical refining of gold. In this process, an electric current is passed through the solution, causing the gold ions to deposit onto cathodes. FRT Machinery offers state-of-the-art electrowinning cells that improve the efficiency of gold deposition, ensuring a higher yield of pure gold. These cells are designed with features that promote better ion mobility and reduce energy consumption, making them ideal for large-scale operations.

Precipitation: An Alternative in Chemical Refining Gold

Another technique used in the chemical refining of gold is precipitation, which involves adding a reagent that reacts with the gold ions in solution, causing them to precipitate out as solid particles. Zinc dust is commonly used for this purpose. FRT Machinery provides specialized precipitation tanks that optimize the reaction conditions, leading to more effective gold recovery. These tanks are equipped with stirring mechanisms to ensure uniform mixing, which is crucial for achieving complete precipitation.

Smelting: Finalizing the Chemical Refining of Gold

After the gold has been recovered from the solution, either through electrowinning or precipitation, it undergoes smelting—a high-temperature process that further purifies the gold by removing remaining impurities. FRT Machinery’s smelting furnaces are engineered to reach and maintain the extremely high temperatures required for gold purification. They are also designed with advanced emission control systems to manage the release of potentially harmful gases, ensuring compliance with environmental standards.

Environmental Considerations in Chemical Refining Gold

The chemical refining of gold, like any industrial process, carries potential environmental impacts. At FRT Machinery, we prioritize sustainability and have implemented measures to mitigate these effects. Our equipment is designed to minimize waste and recycle water, reducing overall resource consumption. Additionally, we continuously research and develop new technologies aimed at decreasing the use of hazardous chemicals, promoting a safer and greener refining process.

Innovative Solutions from FRT Machinery for Chemical Refining Gold

FRT Machinery is committed to pushing the boundaries of what is possible in gold refining. Through ongoing research and development, we are constantly improving our existing technologies and inventing new ones. Our goal is to provide the mining industry with the most efficient, reliable, and environmentally friendly solutions for chemical refining gold. Whether it’s enhancing leaching efficiency or developing novel smelting techniques, FRT Machinery remains at the forefront of innovation in this field.