Diy Gold And Silver Smelting

Diy Gold And Silver Smelting: Crafting Your Precious Metals

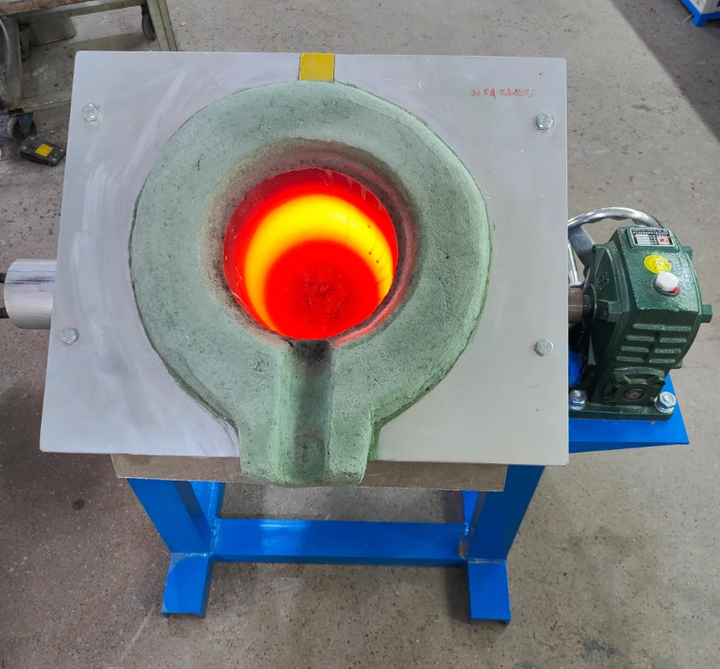

Diy Gold And Silver Smelting Equipment: Essential Tools for Success

When embarking on the journey of DIY gold and silver smelting, having the right tools can make all the difference. FRT Machinery offers a range of equipment designed specifically for this purpose. From furnaces to crucibles, ensuring you have quality materials is key. A good furnace should be able to reach temperatures upwards of 1700°F for silver and over 2000°F for gold. Crucibles must be made from materials like graphite or clay bonded with magnesium oxide to withstand these extreme temperatures without compromising the integrity of your precious metals.

Safety Measures for Diy Gold And Silver Smelting: Protecting Yourself and Others

Safety should always come first when dealing with high temperatures and potentially hazardous materials. Protective gear such as heat-resistant gloves, safety goggles, and face masks are non-negotiable. Ventilation is also crucial; working in a well-ventilated area or using a fume hood can prevent inhalation of toxic fumes. Additionally, keeping a fire extinguisher nearby is a smart precautionary measure. FRT Machinery recommends following all manufacturer guidelines closely to ensure safe operation of all equipment.

Choosing the Right Flux for Diy Gold And Silver Smelting: Enhancing Your Process

The choice of flux plays a vital role in successful smelting. Fluxes help separate impurities from the metal by creating slag—a layer of waste material that floats on top of the molten metal. For gold and silver smelting, borax is commonly used due to its ability to lower the melting point of contaminants. However, for more efficient separation, especially in commercial settings, FRT Machinery suggests using specialized fluxes tailored to specific metal types. These can significantly improve the purity of your final product.

Techniques for Efficient Diy Gold And Silver Smelting: Tips from Experts

Mastering techniques can elevate your smelting process from amateur to professional level. One effective method is called cupellation, primarily used for refining silver. This involves heating silver alloy in a special crucible called a cupel (usually made of bone ash) until the silver melts and collects at the bottom while lead oxides form a residue on top. For gold, parting is often employed where aqua regia—a mixture of nitric and hydrochloric acids—is used to dissolve gold, leaving base metals behind. FRT Machinery provides detailed guides on these techniques, helping enthusiasts achieve better results.

Troubleshooting Common Issues in Diy Gold And Silver Smelting: Solutions at Your Fingertips

Even experienced smelters encounter problems. One common issue is the formation of dross—a scum of impurities—on the surface of molten metal. While unavoidable, proper stirring and skimming can minimize its impact. Another challenge is achieving consistent temperature control within the furnace. Using thermocouples or infrared thermometers can help maintain the ideal heat levels necessary for efficient smelting. FRT Machinery’s customer support team is always ready to assist with troubleshooting tips and advice.

Benefits of Diy Gold And Silver Smelting: Why It’s Worthwhile

Engaging in DIY gold and silver smelting opens up numerous possibilities. Not only does it allow for cost-effective recovery of precious metals from scrap, but it also provides a deeper understanding of metallurgy principles. Furthermore, crafting jewelry or other items from self-smelted gold and silver adds a personal touch that cannot be replicated through commercial means. With FRT Machinery’s reliable equipment and expert guidance, turning raw materials into beautiful artifacts becomes both feasible and rewarding.