Diy Smelting Gold At Home

DIY Smelting Gold at Home: A Comprehensive Guide

Smelting gold at home can be a rewarding endeavor for hobbyists and those interested in refining precious metals. However, it’s essential to understand the process thoroughly, invest in quality equipment such as that provided byFRT Machinery, and take all necessary safety precautions. This guide will walk you through the steps involved in smelting gold at home, from gathering materials to refining your gold.

Preparing Materials for Gold Smelting

Before you begin the smelting process, you need to prepare your materials. This includes collecting gold ore or scrap gold, fluxes, and protective gear. Fluxes are crucial in the smelting process as they help separate impurities from the gold.FRT Machineryoffers specialized kits designed specifically for this purpose, making it easier for beginners to get started.

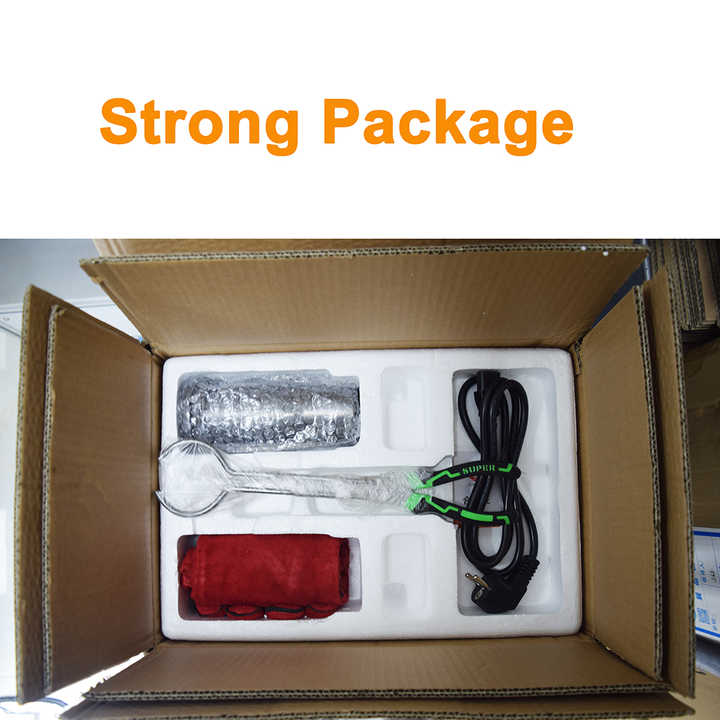

Selecting the Right Equipment for Home Smelting

Choosing the right equipment is critical when setting up your home smelting station. You’ll need a crucible capable of withstanding high temperatures, a heat source like a propane torch or a furnace, and tools for handling molten metal safely.FRT Machineryprovides durable and efficient furnaces suitable for home use, ensuring that you achieve optimal results without compromising on safety.

Safety Precautions During Gold Smelting

Safety must always come first when dealing with high temperatures and potentially hazardous materials. Always wear appropriate protective gear, including heat-resistant gloves, goggles, and a respirator mask. Ensure proper ventilation and have a fire extinguisher nearby.FRT Machineryemphasizes safety in all its product designs, offering solutions that prioritize user protection during the smelting process.

The Smelting Process: Step-by-Step

Now that you have everything prepared, let’s dive into the actual smelting process. Start by heating your crucible in the furnace until it reaches the melting point of gold (about 1,948°F or 1,064°C). Add your gold material along with fluxes to aid in purifying the metal. Once melted, carefully pour the molten gold into a mold to cool and solidify.FRT Machinery’s instructional manuals provide detailed guidance on each step, helping users achieve successful outcomes every time.

Refining Your Gold After Smelting

After smelting, your gold may still contain some impurities. Refining is the next step to achieve pure gold. Electrolysis and chemical leaching are common methods used for refining. These processes require careful handling and specific equipment, whichFRT Machineryalso supplies. Follow these steps precisely to ensure you end up with high-purity gold.

Cleaning Up and Storing Your Equipment

Once your smelting session is complete, allow all equipment to cool down completely before cleaning. Store your tools and any remaining materials securely, away from children and pets. Regular maintenance of your smelting equipment will extend its lifespan and maintain efficiency.FRT Machineryrecommends best practices for upkeep, ensuring that your investment remains valuable over time.

Conclusion: Embracing the Art of DIY Gold Smelting

DIY gold smelting at home can be a fascinating hobby that combines science, art, and practical skills. With the right preparation, equipment, and safety measures in place, you can successfully smelt and refine gold in the comfort of your own space.FRT Machinerysupports enthusiasts at every level, providing the tools and knowledge necessary to turn this ancient craft into a modern-day passion. Whether you’re a seasoned pro or just starting out, embracing the art of smelting opens up endless possibilities for creativity and discovery.