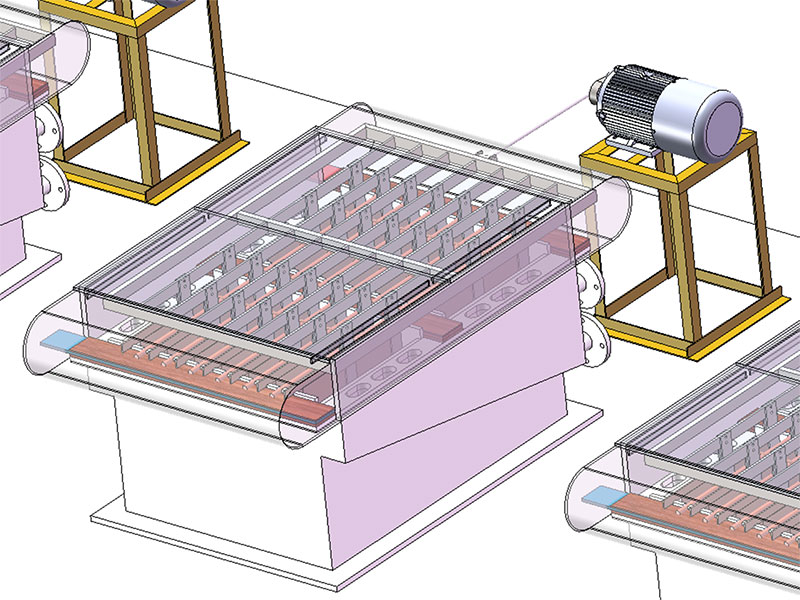

Electrolytic Cell

Features of the electrolytic cell:

1. Improve the on-site working environment: The electrolytic equipment uses a refrigerator to cool the electrolyte. When the electrolytic cell is running, the refrigerator temperature is set to 40℃. When the electrolyte temperature reaches 40℃, the refrigerator automatically starts to cool the electrolyte. When the temperature drops below 40℃, the refrigerator automatically stops running. The electrolyte is not easy to volatilize when electrolyzed at a reasonable temperature. Compared with the old process, the on-site working environment is significantly improved.

2. Fast electrolysis speed and significantly improved output: Fast electrolysis speed, traditional silver electrolysis current density 300/㎡ (silver electrolysis current density 750A/m²). The current density is 2-3 times that of the current conventional silver electrolytic cell, and the production capacity is greatly improved. Under the same production capacity, the required production workshop area is small. According to the current operating current of 1500A, the actual output is 55Kg per hour, reaching the designed production capacity of 1000Kg/day, which greatly reduces the occupation and loss of silver in the production process, and greatly reduces the company’s working capital and financial costs.

3. Easy operation for workers, saving time and effort:

The silver powder precipitated on the cathode is scraped off the mechanical conveyor belt at the bottom of the tank by mechanized conveyor belt, and then transported out of the electrolytic cell through the slope structure at the front of the tank, and directly falls into the car transporting silver powder for washing and ingot casting. Reduce the labor intensity of workers.

The automatic stirring device is adopted, and the silver powder produced on the cathode plate is automatically scraped off, without manual scraping, avoiding the short circuit between the cathode and the anode, which not only improves the reliability of the electrolytic cell operation, but also stops production once a month to clean the bottom of the tank. Now it is stopped for cleaning for nearly 7 months of continuous production. Reduce the labor intensity of workers.

4. Energy saving:

Silver electrolysis has an automatic stirring device to avoid the short circuit between the cathode and the cathode. There is no silver powder in the anode bag, and a large amount of nitric acid can be saved when treating the anode mud. According to current statistics, the daily nitric acid consumption for boiling anode mud has been reduced from 400Kg/day to 300Kg/day.

The daily consumption of nitric acid is reduced by 100 kg, and the daily production of nitrogen oxides is reduced by 36.5 kg. According to the data of the previous test, the nitrogen oxide content is calculated at an air volume of 7000 m3 per hour, and the nitrogen oxide emission is reduced, which saves the cost of subsequent treatment.

5. Improve the operation stability of the electrolytic cell: The new silver electrolytic cell adopts a new electrolyte circulation method, changes the circulation flow direction of the electrolyte in the electrolytic cell, and adopts a parallel flow method with the arrangement of the cathode and cathode, which effectively reduces the concentration polarization between the cathode and cathode. On the premise of ensuring that the quality of the silver powder reaches the national standard No. 1 silver, the current density of electrolytic production is greatly increased, and the silver ion concentration in the electrolyte is reduced.

Advantages:

1. Closed electrolytic cell, flue gas side extraction;

2. Single cell produces 100 kg per day, accounting for 600 liters of electrolyte; single output daily output is 200 kg, accounting for 1000 liters of electrolyte, single output daily output is 300 kg, accounting for 1500 liters of electrolyte.

3. The equipment occupies a small area;

4. Single tank electrolysis, electrolysis for different anodes, the silver powder produced does not contaminate each other.