Eternal Gold Smelting

Introduction to Eternal Gold Smelting: Transforming Precious Metals with Precision

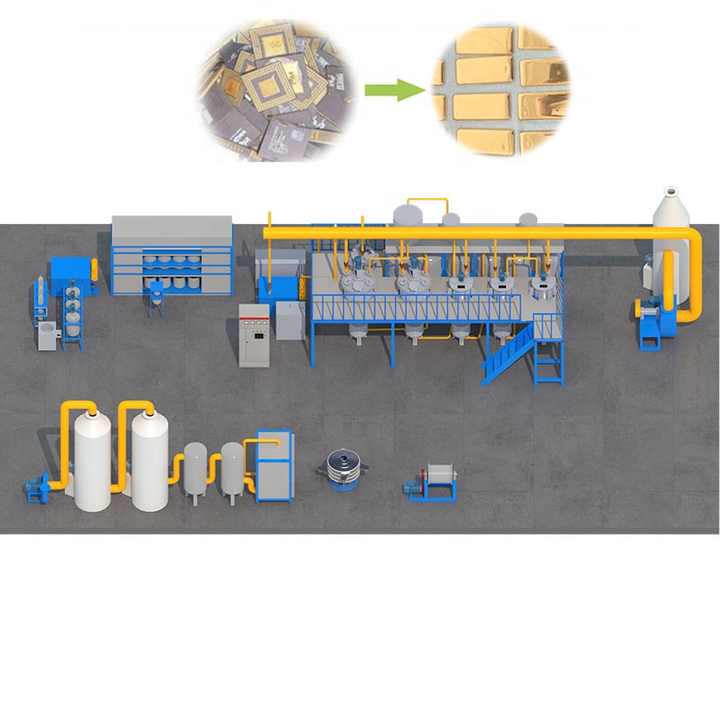

In the realm of precious metal processing, gold smelting stands out as a cornerstone technique that has evolved significantly over the centuries. From ancient civilizations to modern industrial practices, the process of smelting gold—transforming raw ore into pure gold—has been refined for efficiency and sustainability. FRT Machinery, a leader in mechanical equipment, introduces innovative solutions designed to enhance the gold smelting process, ensuring higher purity and reduced environmental impact.

Eternal Gold Smelting: The Process

Eternal gold smelting involves heating gold ore to high temperatures to separate the metal from its impurities. This process requires specialized furnaces capable of reaching and maintaining temperatures upwards of 1,000 degrees Celsius. FRT Machinery’s state-of-the-art furnaces are engineered with advanced insulation materials and efficient heating elements, ensuring minimal energy consumption while achieving optimal smelting conditions.

Advantages of Using FRT Machinery for Eternal Gold Smelting

When it comes to gold smelting, choosing the right equipment is crucial for achieving high-quality results. FRT Machinery offers several advantages over traditional smelting methods:

1.Energy Efficiency: Our furnaces are designed to use less energy without compromising on performance.

2.Environmental Impact: With a focus on reducing emissions and waste, our systems help minimize the carbon footprint associated with gold smelting.

3.Automation: Advanced control systems allow for precise temperature regulation and automated processes, enhancing productivity and consistency.

Innovative Technologies in Eternal Gold Smelting

FRT Machinery is committed to pushing the boundaries of what’s possible in gold smelting through continuous innovation. By integrating cutting-edge technologies such as AI-driven process optimization and IoT-enabled monitoring, we ensure that every step of the smelting process is streamlined and optimized for maximum efficiency.

Sustainability in Eternal Gold Smelting

Sustainability is at the heart of FRT Machinery’s approach to gold smelting. Recognizing the importance of responsible resource management, our equipment is designed to reduce water usage, recycle heat, and minimize the emission of harmful gases. This commitment to sustainability not only benefits the environment but also supports long-term operational viability for our clients.

Customization Options for Eternal Gold Smelting

Every operation is unique, which is why FRT Machinery offers a wide range of customization options tailored to specific needs. Whether you require modifications in furnace size, material handling systems, or integration with existing infrastructure, our team works closely with you to design a solution that perfectly fits your requirements.

Support and Maintenance for Eternal Gold Smelting Equipment

Investing in high-quality smelting equipment is just the beginning. To ensure uninterrupted operations and longevity of your machinery, FRT Machinery provides comprehensive support and maintenance services. Our dedicated team is always available to assist with installation, regular maintenance checks, and any technical issues that may arise, keeping your smelting process running smoothly.

By embracing the latest advancements in technology and adhering to stringent sustainability standards, FRT Machinery sets a new benchmark in eternal gold smelting. Whether you’re a small-scale operation looking to upgrade or a large enterprise seeking to optimize your production, our solutions are designed to meet your needs effectively and responsibly.