Flux Gold Smelting

Understanding Flux Gold Smelting: Enhancing Efficiency and Recovery

Gold smelting is a crucial process for extracting and purifying gold from its ore. Among various methods, flux gold smelting stands out for its efficiency and effectiveness. This technique involves the use of fluxes to separate precious metals from impurities, making it a preferred choice among professionals. FRT Machinery, a leader in providing innovative solutions for the mining industry, offers state-of-the-art equipment designed specifically for flux gold smelting processes.

Flux Gold Smelting Process: A Step-by-Step Guide

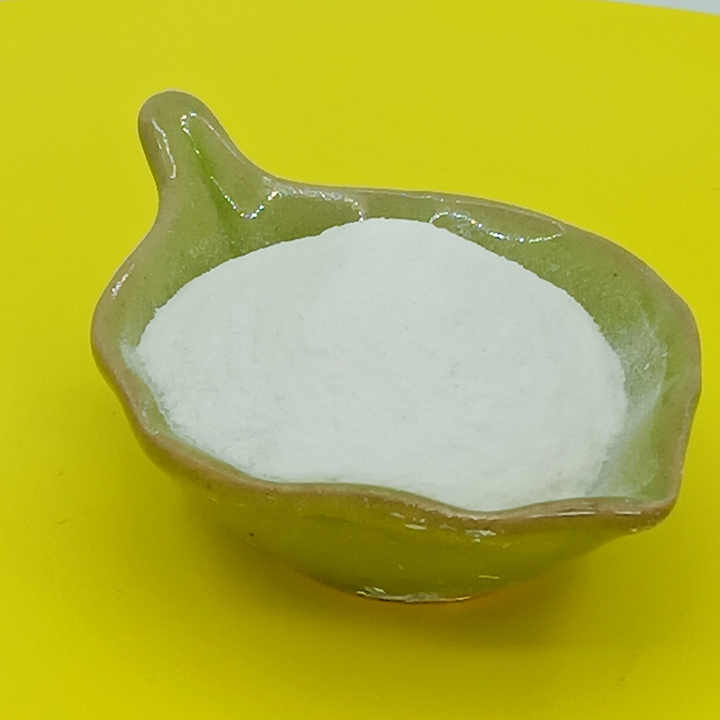

The first step in understanding how flux gold smelting works is to familiarize oneself with the process itself. It begins by crushing the ore into smaller pieces, which are then mixed with flux materials. These fluxes, typically consisting of silica, soda ash, or borax, help lower the melting point of the non-metallic components in the ore. As a result, during the smelting process, these components melt and separate from the gold, allowing for easier extraction.

Benefits of Using Flux in Gold Smelting

Incorporating flux into the gold smelting process brings several benefits. One of the most significant advantages is the increased efficiency of metal recovery. By using flux, the smelting temperature can be reduced, thereby saving energy and reducing operational costs. Additionally, the flux helps to create a slag layer that floats on top of the molten metal, effectively trapping impurities and protecting the precious metals below from oxidation.

Flux Gold Smelting Equipment by FRT Machinery

FRT Machinery has developed specialized equipment tailored for flux gold smelting operations. Their high-tech furnaces are designed to operate at optimal temperatures, ensuring that the flux melts correctly and facilitates efficient separation of gold from other elements. The equipment is also built with durability and ease of maintenance in mind, making it ideal for both small-scale and large-scale mining operations.

Safety Considerations in Flux Gold Smelting

Safety is paramount when dealing with high temperatures and chemicals involved in the smelting process. Proper protective gear must be worn at all times, including heat-resistant gloves, face shields, and respirators. Moreover, FRT Machinery’s smelting equipment includes advanced safety features such as automatic shut-off mechanisms and temperature control systems to prevent accidents and ensure a safe working environment.

Environmental Impact of Flux Gold Smelting

While gold smelting is essential for the mining industry, it’s important to consider its environmental impact. Traditional smelting methods can release harmful emissions and waste products. However, by utilizing flux in the process, some of these negative effects can be mitigated. For instance, the slag produced can be recycled or used in construction materials, reducing waste. Furthermore, FRT Machinery continuously works on improving their technology to reduce emissions and promote sustainable practices within the industry.

Future Innovations in Flux Gold Smelting

As technology advances, so too does the potential for innovation in flux gold smelting. Research is ongoing into developing new flux compositions that could further enhance the efficiency of the process while reducing its environmental footprint. FRT Machinery remains at the forefront of these developments, committed to pushing the boundaries of what’s possible in gold smelting technology. With a focus on sustainability and efficiency, they aim to set new standards for the industry, ensuring that gold smelting remains both profitable and responsible.