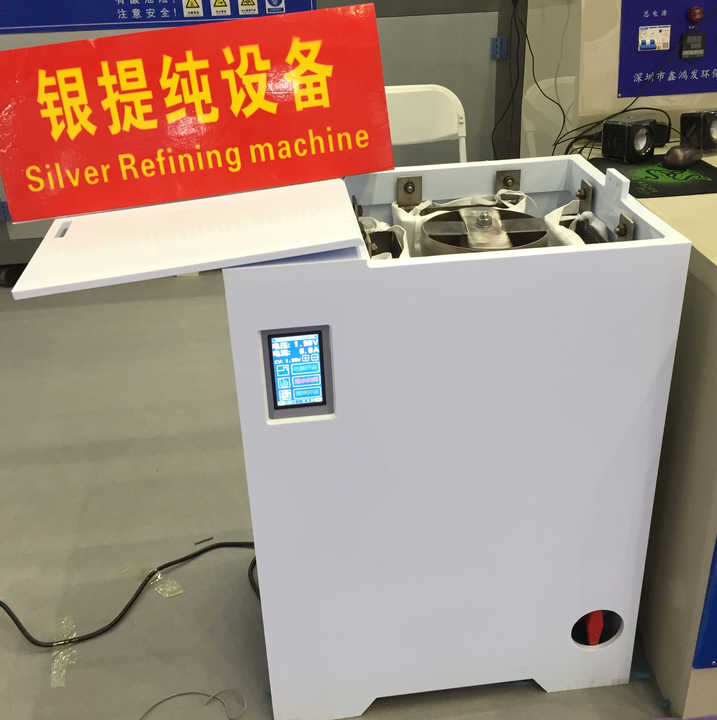

gold and silver smelting equipment

Gold and Silver Smelting Equipment: Essential Tools for Precious Metal Refining

Gold and silver smelting equipment plays a vital role in the process of refining precious metals. This equipment enables the efficient melting, separation, and purification of gold and silver from ores or scrap materials. In this article, we will explore the types of gold and silver smelting equipment, their functions, and the considerations for choosing the right tools for successful smelting operations.

Overview of Gold and Silver Smelting Equipment

Smelting equipment is used to heat and melt gold and silver to separate these metals from impurities. The equipment must be capable of reaching and maintaining high temperatures to effectively refine the metals. The choice of equipment depends on factors such as the scale of operations, the type of material being processed, and the desired purity of the final product.

Types of Gold and Silver Smelting Equipment

Furnaces

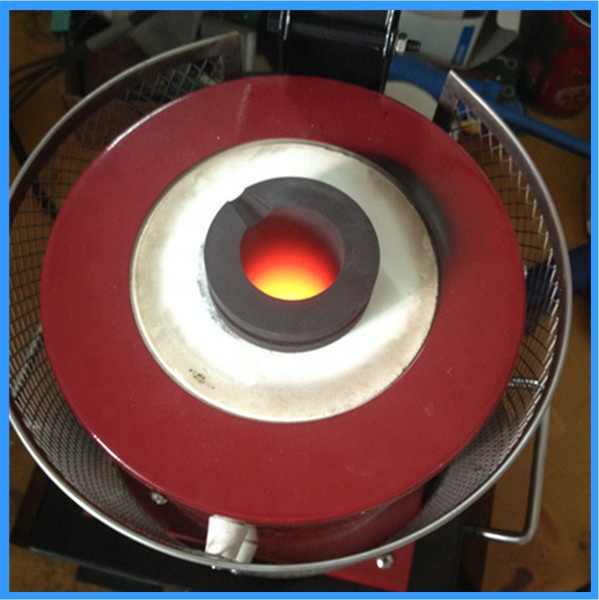

Furnaces are the cornerstone of any smelting operation. They provide the high temperatures necessary for melting gold and silver. There are several types of furnaces used in gold and silver smelting:

- Electric Furnaces: These furnaces use electrical resistance to generate heat. They offer precise temperature control and are suitable for small to medium-scale operations. Electric furnaces are popular for their efficiency and ability to maintain consistent temperatures.

- Gas Furnaces: Gas-fired furnaces use propane or natural gas to produce heat. They are commonly used in larger-scale operations due to their high heating capacity and versatility. Gas furnaces are ideal for continuous smelting processes.

- Induction Furnaces: Induction furnaces use electromagnetic induction to heat the metal. They are known for their rapid heating capabilities and energy efficiency. Induction furnaces are often used for both gold and silver smelting in industrial settings.

Crucibles

Crucibles are heat-resistant containers used to hold molten gold and silver during the smelting process. They are made from materials such as graphite, ceramic, or stainless steel. The choice of crucible material depends on its ability to withstand high temperatures and resist chemical reactions with the metal and fluxes.

Fluxes

Fluxes are chemicals added to the gold and silver during smelting to facilitate the removal of impurities. Common fluxes include borax, soda ash, and silica. Fluxes help lower the melting point of the metals and form a slag that can be easily separated from the molten metal. The proper selection of fluxes is crucial for achieving high purity in the final product.

Safety Gear

Safety gear is essential for protecting operators during the smelting process. Key items include:

- Protective Gloves: To handle hot materials and avoid burns.

- Safety Glasses and Face Shields: To protect against splashes and fumes.

- Heat-Resistant Aprons: To shield the body from intense heat.

Applications of Gold and Silver Smelting Equipment

Jewelry Manufacturing

In jewelry making, gold and silver smelting equipment is used to melt and purify scrap metals or to create custom pieces. The ability to control the purity of the metals is essential for producing high-quality jewelry.

Metal Recycling

Smelting equipment is also used in metal recycling operations to recover gold and silver from electronic waste, old coins, and other scrap materials. This process helps in recycling valuable metals and reducing environmental impact.

Mining Operations

In mining operations, gold and silver smelting equipment is used to process ore extracted from the ground. The equipment helps in separating valuable metals from waste materials, increasing the efficiency of the mining process.

Considerations for Choosing Gold and Silver Smelting Equipment

Scale of Operation

The scale of your smelting operation will influence the type and size of equipment required. Small-scale operations may benefit from electric furnaces and smaller crucibles, while larger operations may require gas or induction furnaces and larger crucibles.

Temperature Control

Accurate temperature control is crucial for successful smelting. Choose equipment that offers precise temperature management to ensure optimal melting and refining of gold and silver.

Material Compatibility

Ensure that the equipment is compatible with the types of gold and silver you plan to process. Different materials and fluxes may require specific types of crucibles and furnaces.

Safety Features

Safety should always be a top priority. Select equipment that includes safety features such as automatic shut-off systems, proper ventilation, and robust safety gear to protect operators and the environment.

Gold and silver smelting equipment is essential for refining precious metals and achieving high purity levels. By understanding the types of equipment available and their applications, you can make informed decisions for your smelting operations. Whether for jewelry making, metal recycling, or mining, investing in the right smelting equipment ensures efficient and effective processing of gold and silver.