Gold Electrolysis Equipment

The gold electrolysis unit is a device that uses electrolysis to purify crude gold with a gold content of more than 95% to 99.99%. It uses crude gold as anode, titanium sheet or pure gold as cathode, chloroauric acid solution as electrolyte, and DC/AC/DC superposition power supply to dissolve crude gold at the anode and precipitate pure gold at the cathode to achieve the purification effect.

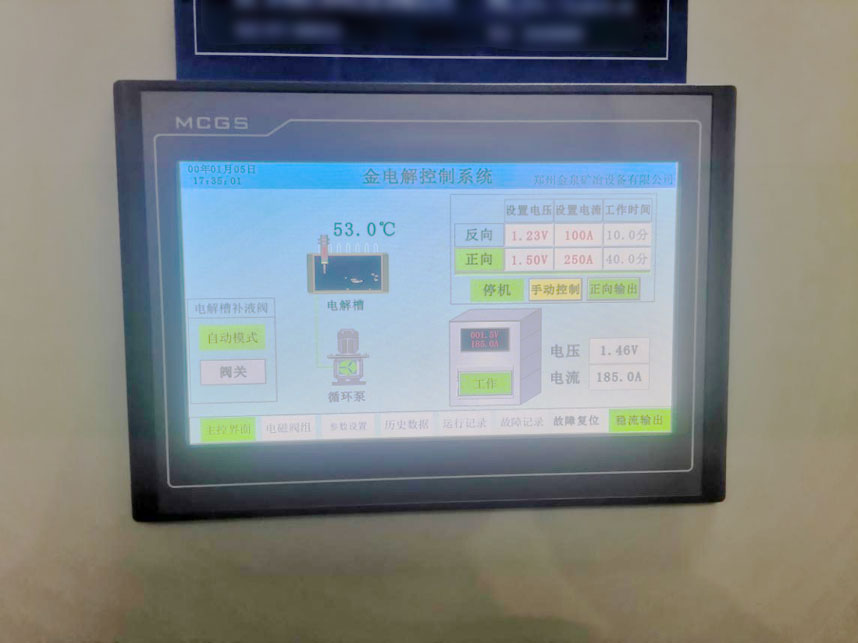

1. The cathode current density is as high as 1000A/M2

2. Automatic control of electrolyte temperature;

3. Titration and replenishment to maintain the electrolyte level;

4. The electrolyte maintains a self-circulating state;

Advantages

1. The product quality is stable and can meet the Au99.99 (first-level) gold ingot standard of the Shanghai Gold Exchange; according to the special needs of customers, it can also produce 99.999% pure gold ingots through secondary electrolysis;

2. Low production cost: about 0.02 yuan/gram of gold;

3. The electrolysis uses AC/DC superposition power supply, which can effectively prevent the production of silver chloride on the gold anode, making the anode plate electrolysis more thorough;

4 , high current density electrolysis technology, high production efficiency;

5. Transparent closed fume hood, good working environment, easy to operate, beautiful and generous, the whole set of equipment occupies about 4m2;

6. Equipped with flue gas condensation device, because the gold electrolysis process requires a high temperature (60-70℃), the flue gas condensation device can condense and reflux the volatile electrolyte to avoid gold loss;

7. The main body of the equipment is made of high-performance polypropylene material, and anti-aging agent is added to the material to greatly extend the service life of the equipment; the overall bracket material is PPH, which is extremely corrosion-resistant; the cathode and anode conductive strips are made of titanium-clad copper with excellent conductivity.