Gold Plated Refining

Gold Plated Refining: Elevating Quality and Efficiency

Gold plated refining is a specialized process that enhances the purity and quality of gold, making it suitable for high-end applications. This technique not only increases the value of the metal but also opens up new avenues in industries where precision and purity are paramount. FRT Machinery, a leader in the field, offers cutting-edge solutions designed to streamline this process while ensuring environmental sustainability.

Gold Plated Refining Techniques

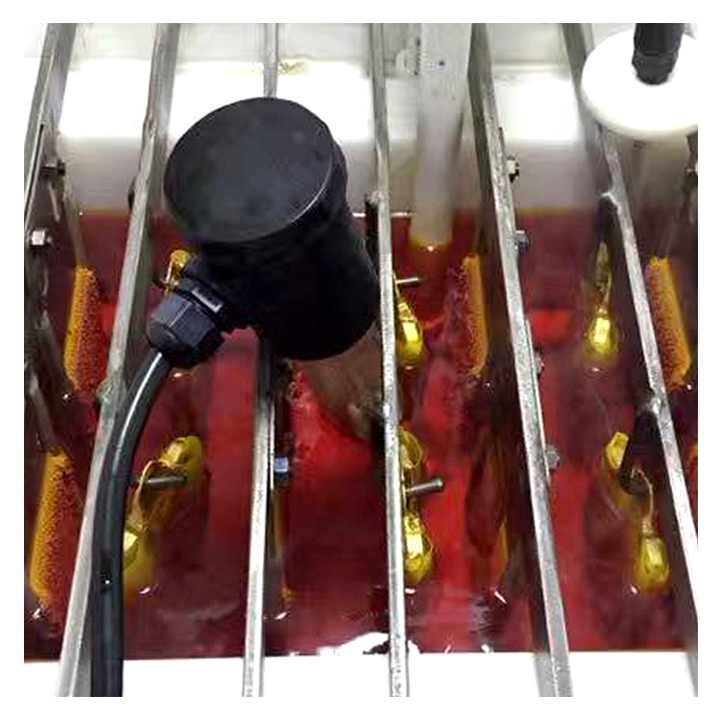

Understanding the nuances of gold plated refining techniques is crucial for maximizing efficiency and output. One of the most common methods involves electroplating, where a thin layer of gold is deposited onto a conductive substrate. This process requires precise control over variables such as current density, temperature, and pH levels to achieve uniform plating. FRT Machinery’s advanced systems provide unparalleled accuracy in these parameters, ensuring consistent results every time.

Benefits of Gold Plated Refining

The benefits of gold plated refining extend beyond enhancing the aesthetic appeal of jewelry. In industrial applications, this process can significantly improve the conductivity and corrosion resistance of components used in electronics, aerospace, and medical devices. By investing in gold plated refining, manufacturers can produce products that are more reliable and longer-lasting, thereby reducing maintenance costs and increasing customer satisfaction.

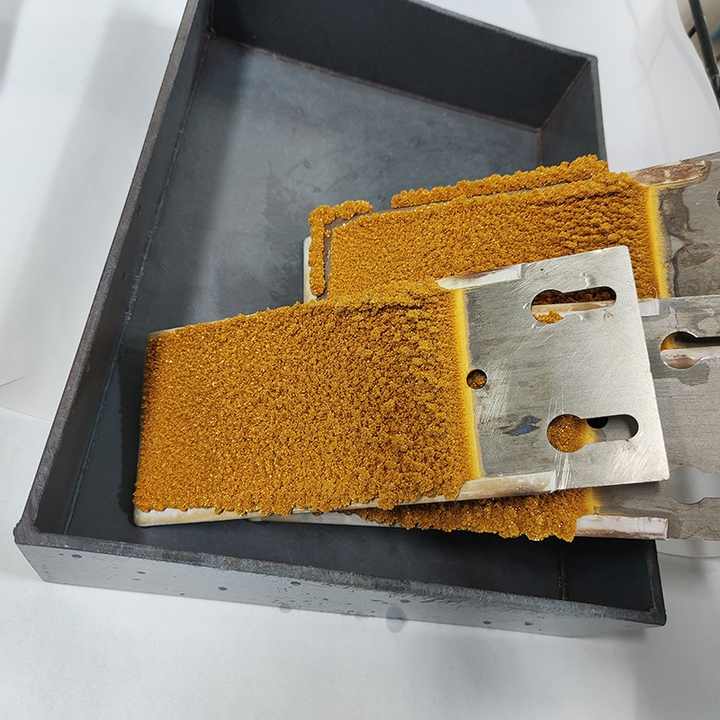

Equipment for Gold Plated Refining

Selecting the right equipment is fundamental to successful gold plated refining. FRT Machinery offers a range of machines tailored to meet specific industry needs. These include electroplating tanks, filtration systems, and automation technologies that enhance productivity while minimizing waste. Each piece of equipment is designed with durability and user-friendliness in mind, ensuring that operators can focus on quality control rather than maintenance issues.

Environmental Impact of Gold Plated Refining

As awareness grows regarding the environmental impact of manufacturing processes, companies are increasingly seeking ways to reduce their ecological footprint. Gold plated refining, when done correctly, can be both efficient and eco-friendly. FRT Machinery’s systems incorporate features like water recycling and energy-efficient designs, which help minimize resource consumption and waste generation. By adopting these practices, businesses can contribute positively to sustainability goals without compromising on operational excellence.

Future Trends in Gold Plated Refining

Looking ahead, the future of gold plated refining is likely to be shaped by technological advancements and changing market demands. Innovations in nanotechnology, for instance, promise to revolutionize how thin films are applied, potentially opening up new possibilities for product design and functionality. Moreover, there is a growing trend towards circular economy principles, which encourages the reuse and recycling of materials. FRT Machinery is committed to staying at the forefront of these developments, continuously improving its offerings to meet the evolving needs of its clients.

Conclusion

In conclusion, gold plated refining represents a strategic investment for companies aiming to enhance product quality and market competitiveness. With FRT Machinery’s support, businesses can harness the power of this technology to drive growth and innovation, all while contributing to a more sustainable future. Whether you’re part of the jewelry industry or involved in high-tech manufacturing, embracing gold plated refining could be the key to unlocking new opportunities and achieving long-term success.