Gold Plated Scrap Smelting

Gold Plated Scrap Smelting: A Comprehensive Guide

Gold plated scrap represents a valuable resource for recycling and reclamation. Whether from outdated electronics, jewelry, or industrial components, the process of smelting this scrap can recover precious metals efficiently and sustainably. FRT Machinery, a leading manufacturer in the field, offers insights into the techniques and technologies essential for gold plated scrap smelting.

Understanding Gold Plating and Its Recovery

Gold plating involves coating a base metal with a thin layer of gold to enhance its appearance or functionality. Commonly used in electronics due to its excellent conductivity, gold plating also adorns jewelry and decorative items. When these products reach their end-of-life, recovering the gold becomes economically and environmentally beneficial. FRT Machinery’s advanced smelting solutions facilitate this recovery process, ensuring minimal waste and maximum efficiency.

Preparation of Gold Plated Scrap for Smelting

Before smelting, gold plated scrap must undergo preparation steps to ensure optimal results. This includes sorting materials based on their composition and removing non-metallic parts. FRT Machinery provides specialized equipment designed to streamline these processes, making it easier to prepare gold plated scrap for smelting. Proper preparation enhances the purity of recovered gold and reduces contamination risks during the smelting phase.

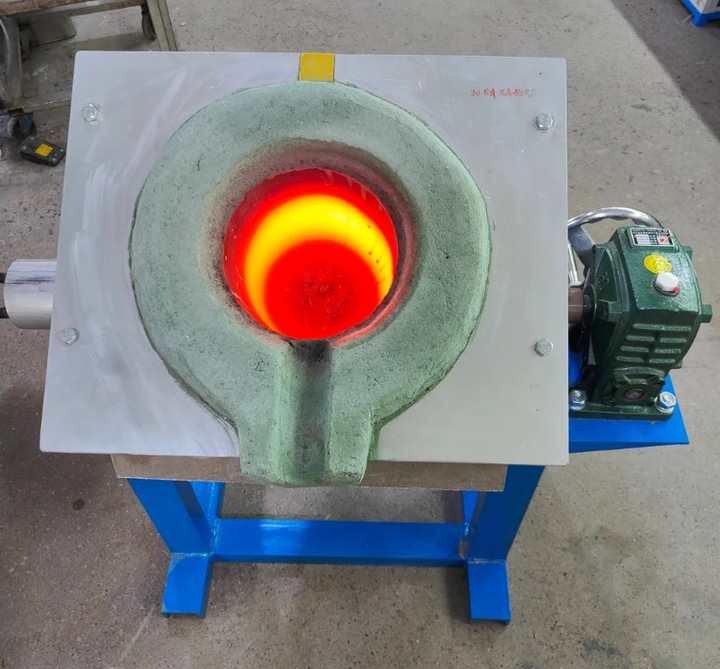

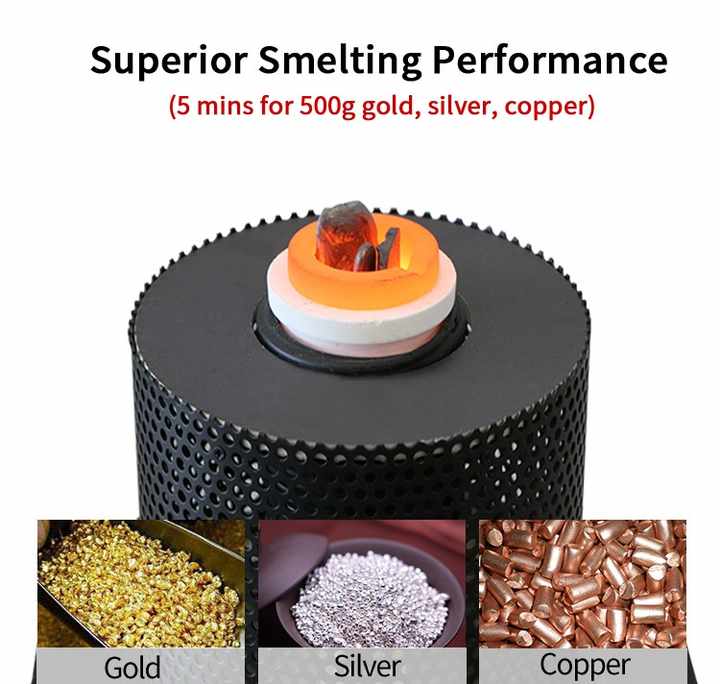

Techniques for Efficient Gold Plated Scrap Smelting

Several techniques can be employed for smelting gold plated scrap, each offering unique advantages depending on the scale and type of operation. FRT Machinery recommends considering factors such as energy consumption, environmental impact, and operational costs when selecting a smelting technique. Popular methods include induction furnaces, which provide precise temperature control, and crucible melting systems, ideal for smaller batches.

Environmental Considerations in Gold Plated Scrap Smelting

Given the potential environmental impacts associated with smelting operations, adopting eco-friendly practices is crucial. FRT Machinery emphasizes the importance of using energy-efficient equipment and implementing waste management strategies to minimize ecological footprints. By choosing sustainable smelting technologies, businesses can contribute positively to both profitability and environmental stewardship.

Quality Assurance in Gold Plated Scrap Smelting

Ensuring the quality of recovered gold is paramount for maintaining market trust and achieving high resale values. FRT Machinery integrates rigorous testing procedures throughout the smelting process, from initial material analysis to final product verification. Utilizing state-of-the-art analytical tools, operators can monitor purity levels and adjust parameters as needed, guaranteeing consistent output quality.

Innovative Solutions from FRT Machinery for Gold Plated Scrap Smelting

As technology evolves, so too do the capabilities of smelting equipment. FRT Machinery continuously develops innovative solutions aimed at improving efficiency, safety, and sustainability within the gold plated scrap smelting industry. From automation features that reduce labor requirements to modular designs that allow for easy maintenance and upgrades, FRT Machinery’s offerings support modern recycling efforts effectively.

By following these guidelines and utilizing the latest technologies from FRT Machinery, businesses engaged in gold plated scrap smelting can maximize their returns while minimizing environmental impact. Whether you’re just starting out or looking to upgrade your existing setup, investing in reliable, efficient smelting solutions is key to success in this lucrative field.