Details

- Home

- gold purification methods

gold purification methods

Gold purification is a crucial step in refining raw gold to remove impurities and achieve a high level of purity. Various gold purification methods are available, ranging from ancient techniques to modern scientific approaches. In this article, we will explore the different methods used to purify gold, their advantages and disadvantages, and how they work in practice.

Table of Contents

Toggle1. The Importance of Gold Purification

Purification of gold is essential to ensure that the metal is of high quality and free from impurities such as other metals or minerals. Pure gold is not only more valuable but also more versatile in its applications, ranging from jewelry to industrial uses. Several gold purification methods are employed to refine gold to its purest form, ensuring the best results for different applications.

2. Traditional Gold Purification Methods

Traditional methods of gold purification have been used for centuries and still hold relevance today. These methods often involve basic equipment and processes that were developed long before modern technology.

2.1. The Fire Assay Method

One of the oldest gold purification methods is the fire assay method, also known as cupellation. This method involves melting gold in a furnace with lead and other chemicals to separate impurities. Once the lead melts, it absorbs non-precious metals, leaving pure gold behind.

2.2. Gold Panning

Gold panning is another ancient technique used to separate gold from other materials. By placing gold-bearing soil or rock in a pan and swirling it in water, the heavier gold sinks to the bottom while lighter materials wash away. Although not as precise as other gold purification methods, gold panning remains popular among hobbyists.

3. Modern Gold Purification Methods

With advancements in technology, modern gold purification methods have become more efficient and precise. These methods are widely used in both industrial and artisanal gold refining.

3.1. Aqua Regia

Aqua regia is a highly effective method for purifying gold, involving the use of a mixture of nitric acid and hydrochloric acid. The acids dissolve the gold, allowing impurities to be filtered out. Once the gold is dissolved, it can be precipitated from the solution and recovered in a purified form.

How Aqua Regia Works

Aqua regia dissolves gold by breaking it down into gold chloride, a soluble compound. The solution is then filtered to remove impurities, and a reducing agent is added to precipitate pure gold.

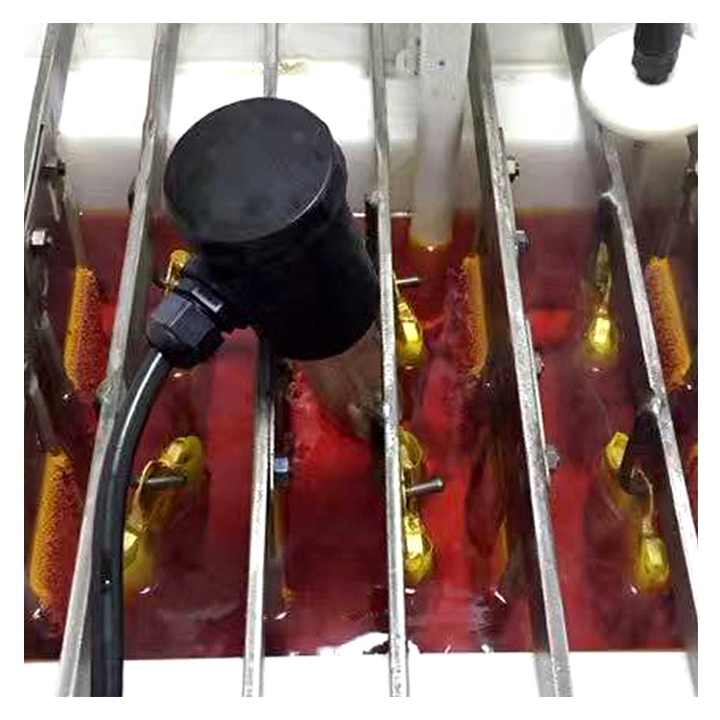

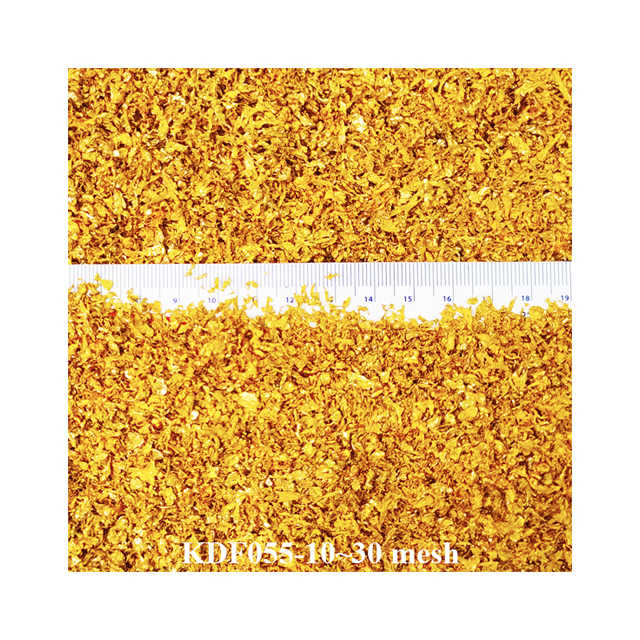

3.2. Electrolytic Refining

Electrolytic refining is one of the most precise gold purification methods, involving the use of an electric current to purify gold. In this process, impure gold is placed in an electrolyte solution, and an electric current is passed through it, causing pure gold to deposit onto a cathode.

Advantages of Electrolytic Refining

Electrolytic refining offers high levels of precision and efficiency, making it suitable for refining gold to a purity of 99.99%. It is widely used in industrial gold refining due to its ability to produce gold of exceptional purity.

3.3. The Miller Process

The Miller process is another modern gold purification technique, which uses chlorine gas to purify molten gold. Chlorine reacts with impurities, forming chloride compounds that rise to the surface and can be removed.

Benefits of the Miller Process

The Miller process is faster and less expensive than electrolytic refining, though it produces gold with slightly lower purity levels. It is often used in combination with other gold purification methods to achieve the highest possible purity.

4. Chemical Gold Purification Methods

Chemistry plays a significant role in many gold purification methods, with various chemicals used to dissolve or separate gold from impurities.

4.1. Acid-Based Gold Purification

Acid-based purification methods, such as aqua regia and the Wohlwill process, rely on chemical reactions to dissolve gold and separate it from impurities. These methods are highly effective for achieving high purity levels, though they require careful handling of corrosive acids.

4.2. The Wohlwill Process

The Wohlwill process is a chemical method that uses electrolysis to purify gold to the highest level of purity, often reaching 99.999%. It is one of the most advanced gold purification methods, producing gold of the highest quality.

5. Smelting as a Gold Purification Method

Smelting is a widely used method for refining metals, including gold. It involves heating the metal to a high temperature to melt it and separate impurities.

5.1. How Smelting Works

In gold smelting, gold ore or impure gold is heated in a furnace along with a flux, which helps to remove impurities. The molten gold sinks to the bottom of the furnace, while impurities form a slag that floats on top and can be removed.

The Role of Flux in Smelting

Flux is a chemical agent that helps bind impurities, making them easier to separate from molten gold. Common fluxes used in gold smelting include borax and silica.

6. Comparing Different Gold Purification Methods

Each gold purification method has its own advantages and disadvantages, making them suitable for different situations and levels of purity required. Below is a comparison of the most common methods.

6.1. Cost and Efficiency

Some methods, such as gold panning and smelting, are more affordable but less efficient at achieving high purity levels. On the other hand, modern methods like electrolytic refining and the Wohlwill process are more expensive but can achieve near-perfect purity.

6.2. Purity Levels

The level of purity required will determine which gold purification method is best. For industrial purposes, methods like the Wohlwill process are preferred, as they produce gold of the highest purity. For artisanal refining, methods like smelting and gold panning may be sufficient.

7. Environmental Impact of Gold Purification Methods

Gold purification can have significant environmental impacts, particularly when chemicals like acids or cyanide are used. It is important for gold refiners to consider environmentally friendly alternatives and adopt practices that minimize waste and pollution.

7.1. Reducing Chemical Waste

Modern gold purification methods have been developed to reduce the use of harmful chemicals, with methods like electrolytic refining and aqua regia offering safer alternatives. Additionally, many gold refiners are adopting recycling practices to reduce waste.

7.2. Eco-Friendly Methods

Some gold refiners are exploring more sustainable gold purification techniques, such as biological gold extraction, which uses microorganisms to recover gold from ore without harmful chemicals.

The range of gold purification methods available today provides refiners with numerous options to achieve high levels of purity. From traditional methods like gold panning and fire assay to modern techniques like aqua regia and electrolytic refining, each method has its own strengths and applications. By choosing the right method, gold refiners can ensure they achieve the highest levels of purity, whether for industrial use, jewelry making, or investment purposes.