gold purification

Gold is one of the most precious metals on Earth, prized for its rarity, beauty, and resistance to corrosion. However, naturally occurring gold is rarely pure. It is often mixed with other metals and impurities that need to be removed before it can be used in various applications. The gold purification process ensures that gold reaches its highest purity levels, making it suitable for investment, jewelry, or industrial purposes. This article will delve into the different methods of gold purification and the equipment used, as well as key considerations when refining this valuable metal.

Methods of Gold Purification

The process of gold purification can be achieved through various methods, depending on the desired level of purity and the nature of the gold ore or scrap. Each method has its advantages and challenges, and understanding these techniques is crucial for achieving optimal results.

1. Chemical Gold Purification

One of the most common methods of gold purification is chemical purification, which involves the use of chemicals to dissolve impurities from the gold.

Aqua Regia Method

Aqua regia is a mixture of nitric acid and hydrochloric acid, and it is one of the most effective solutions for dissolving gold. The gold is placed into the aqua regia solution, where it dissolves. Impurities are then filtered out, leaving behind pure gold. This method is widely used in both industrial and small-scale purification processes due to its effectiveness.

Cyanide Process

The cyanide process is another widely used method for gold purification. In this method, gold is dissolved in a solution of sodium cyanide or potassium cyanide. The gold forms a complex with the cyanide, which can then be separated from other materials. Although effective, this method is controversial due to the toxicity of cyanide, and stringent environmental regulations govern its use.

2. Physical Gold Purification

Physical methods of gold purification involve the mechanical separation of gold from impurities without the use of chemicals.

Miller Process

The Miller process involves blowing chlorine gas through molten gold, causing impurities to form chlorides, which are less dense and rise to the surface, where they can be skimmed off. This method is often used for large-scale gold purification operations and can achieve purity levels of up to 99.5%.

Wohlwill Process

The Wohlwill process is a refinement of the Miller process and involves passing an electric current through a solution containing gold. This electrolytic method results in extremely high purity levels, often reaching 99.99%. It is commonly used for industrial-grade gold purification.

3. Fire Assay Purification

The fire assay method is one of the oldest techniques used in the gold purification process. It involves melting the gold in a high-temperature furnace along with lead, which combines with impurities to form a slag. The gold is then separated from the slag and can be further purified. This method is particularly effective for small quantities of gold.

Equipment for Gold Purification

The gold purification process requires specialized equipment to achieve optimal results. Depending on the chosen method, the necessary equipment can vary, but certain tools are common across most techniques.

1. Crucibles and Furnaces

Crucibles and furnaces are essential for melting gold during the purification process. They must be able to withstand extremely high temperatures and resist reactions with molten gold and impurities.

Graphite Crucibles

Graphite crucibles are often used due to their high thermal conductivity and resistance to chemical reactions. These crucibles can hold molten gold without contaminating it, making them ideal for gold purification.

Induction Furnaces

Induction furnaces provide the precise heat control needed for melting gold during the purification process. They are highly efficient and can be used for small and large-scale operations alike.

2. Chemical Processing Equipment

For chemical methods such as the aqua regia and cyanide processes, specialized equipment is required to handle the hazardous chemicals involved.

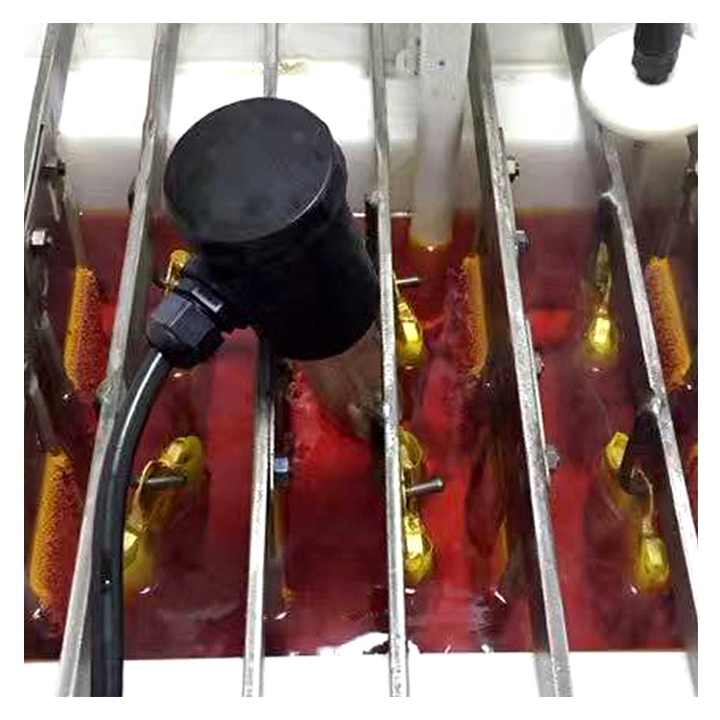

Reaction Vessels

Reaction vessels are used to dissolve gold in acid or cyanide solutions. These vessels must be resistant to corrosion and able to withstand the exothermic reactions that occur during the gold purification process.

Filtration Systems

Filtration systems are essential for separating impurities from gold during chemical purification. These systems ensure that contaminants are removed, leaving behind only pure gold.

Considerations for Gold Purification

There are several factors to consider when purifying gold, especially when choosing the method and equipment that best suits the specific application.

1. Purity Requirements

The level of purity required for the final product will determine the method used for gold purification. Jewelry and investment-grade gold typically require the highest levels of purity, whereas industrial applications may tolerate lower purity levels.

2. Environmental Impact

Certain gold purification methods, particularly those involving toxic chemicals like cyanide, can have significant environmental impacts. It is important to adhere to strict environmental regulations and use safe disposal methods for hazardous waste.

3. Cost of Purification

The cost of gold purification can vary depending on the method and scale of the operation. Chemical methods, while highly effective, may be more expensive due to the need for specialized chemicals and equipment. Physical methods, such as the Miller process, can be more cost-effective for large-scale purification.

Benefits of Gold Purification

The benefits of gold purification go beyond aesthetic appeal and industrial use. Pure gold has a higher market value, is more durable, and is essential for specific applications that demand the highest level of purity.

1. Increased Market Value

Purified gold is worth more than gold containing impurities. This is particularly important for investors and gold dealers who seek to maximize the value of their assets.

2. Enhanced Durability

Impurities can weaken gold, making it less durable. Pure gold is stronger and more resistant to tarnish, ensuring a longer lifespan for products made from purified gold.

3. Critical for Industrial Use

Certain industrial applications, such as electronics manufacturing, require extremely pure gold to ensure the proper functioning of devices. Gold purification is critical for meeting these exacting standards.

The gold purification process is essential for refining this precious metal and ensuring that it meets the high standards required for various applications. Whether through chemical methods like the aqua regia and cyanide processes or physical methods like the Miller and Wohlwill processes, the goal is to remove impurities and produce pure, high-quality gold. Understanding the equipment, methods, and key considerations involved in gold purification allows for the efficient production of this valuable resource.