Gold Refining Company

Gold Refining: Transforming Raw Materials into Precious Metals

In the dynamic landscape of precious metal processing, gold refining stands out as a critical link between raw materials and high-value products. FRT Machinery, a leader in the design and manufacturing of specialized equipment for the mining and metallurgical industries, plays a pivotal role in this process. By focusing on innovation and efficiency, FRT Machinery helps gold refining companies achieve unparalleled purity levels, ensuring that every ounce of gold is maximized for value.

Gold Refining Techniques: Enhancing Purity Levels

Gold refining techniques have evolved significantly over the years, driven by the need for higher purity and more sustainable processes. At the heart of these advancements are technologies developed by FRT Machinery. These include hydrometallurgical and pyrometallurgical methods, which remove impurities and separate gold from other metals or minerals. The choice of technique depends on the form of the raw material and the desired purity level of the final product.

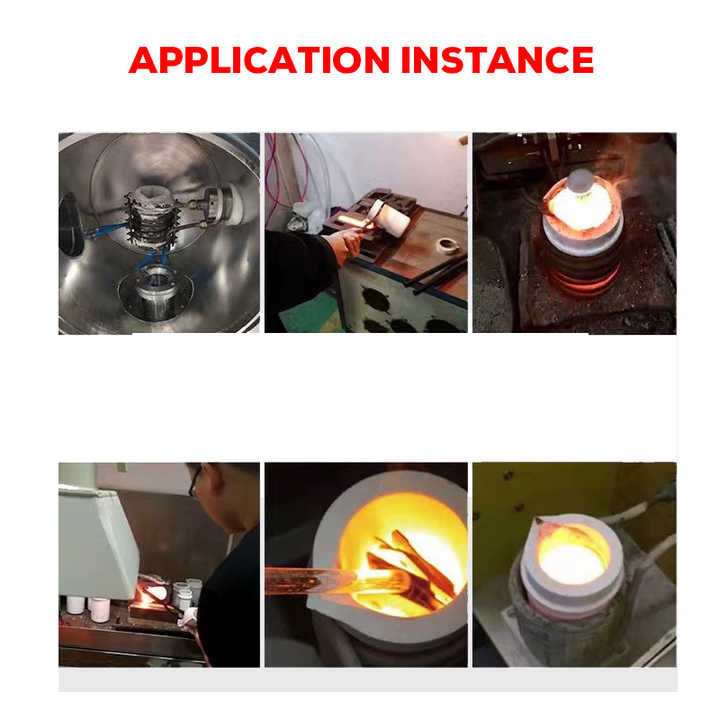

Equipment for Gold Refining: Precision Engineering by FRT Machinery

FRT Machinery offers a comprehensive range of equipment tailored for gold refining operations. This includes furnaces designed for high-temperature melting, electrolysis cells for chemical purification, and filtration systems to remove contaminants. Each piece of equipment is engineered with precision to meet the stringent requirements of the refining process, ensuring that gold reaches its highest possible purity.

Environmental Impact: Green Solutions in Gold Refining

The environmental impact of gold refining has been a concern for many years. Recognizing this, FRT Machinery has developed solutions that minimize waste and reduce emissions. For instance, their advanced filtration systems capture harmful gases and particulates, while recycling technologies recover valuable materials from waste streams. These green initiatives not only protect the environment but also contribute to the sustainability goals of gold refining companies.

Safety Standards in Gold Refining Processes

Safety is paramount in gold refining due to the use of high temperatures and potentially hazardous chemicals. FRT Machinery ensures that all its equipment complies with international safety standards, providing operators with a safer working environment. Features such as automated controls and remote monitoring systems help prevent accidents, making the refining process more reliable and secure.

Cost Efficiency: Maximizing Returns in Gold Refining

Cost efficiency is crucial for profitability in gold refining. FRT Machinery’s innovative designs focus on reducing energy consumption and minimizing downtime, which directly impacts operational costs. Additionally, their maintenance-friendly equipment reduces long-term expenses, allowing refining companies to maximize returns on investment.

Future Trends: Innovations Shaping Gold Refining

Looking ahead, the future of gold refining promises exciting innovations. FRT Machinery continues to invest in research and development, exploring new methods to enhance efficiency and sustainability. From the integration of artificial intelligence for predictive maintenance to the development of cleaner refining techniques, the company is committed to leading the way in technological advancements within the industry.

By focusing on these key areas—techniques, equipment, environmental impact, safety, cost efficiency, and future trends—FRT Machinery supports gold refining companies in achieving excellence. Their dedication to innovation ensures that the industry remains robust, capable of meeting global demand while setting new standards for sustainability and efficiency.