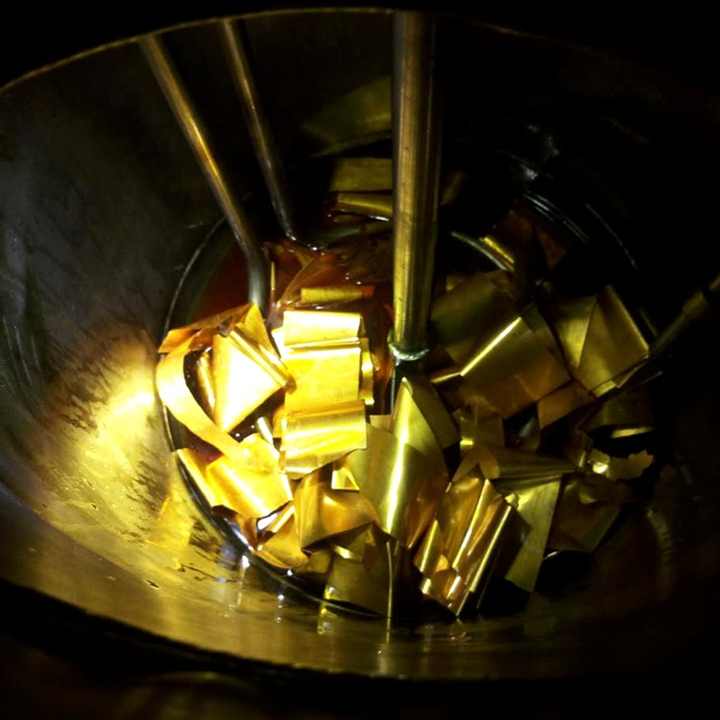

gold refining machine

The Gold Refining Machine A Key to High Purity Gold

Gold refining has always been a vital process in the metal industry, helping to achieve the highest levels of purity in this precious metal. The gold refining machine is one of the most essential tools used to accomplish this task. Whether for industrial purposes or investment, obtaining pure gold is crucial, and the efficiency of a gold refining machine plays a key role in that process.

How Does a Gold Refining Machine Work?

A gold refining machine operates by utilizing various methods to separate impurities from raw gold or gold alloys. One of the most common techniques is electrolysis, where an electric current passes through an electrolyte solution to purify the gold. Another method involves chemical processes that dissolve the impurities while leaving the pure gold behind.

The gold refining machine’s efficiency depends on its design, which typically includes an anode and a cathode for electrolysis-based machines or various chambers and filters for chemical-based systems. As the gold is refined, it becomes purer, allowing it to be used for more specialized purposes.

Key Features of a Gold Refining Machine

A gold refining machine is designed to ensure high levels of precision and purity. Some of the key features include the ability to handle different amounts of raw gold, operate at various temperatures, and offer real-time monitoring of the refining process. Advanced machines also allow for the recycling of by-products, making them more environmentally friendly.

For smaller operations, portable gold refining machines provide flexibility, while larger machines are suitable for industrial-scale refining. These machines are equipped with modern technology to ensure efficiency and safety during the refining process.

Types of Gold Refining Machines

There are several types of gold refining machines, each designed for specific purposes. Understanding these types can help in selecting the best option for a particular application.

Electrolytic Gold Refining Machines

Electrolytic gold refining machines are commonly used due to their ability to produce high-purity gold. This method uses electrolysis to separate gold from impurities, and it is widely adopted in both small-scale and large-scale refineries. The process is precise and allows for continuous operation, making it a popular choice for many industries.

Chemical-Based Gold Refining Machines

Another type of gold refining machine uses chemical processes to dissolve impurities from the gold. These machines typically use acids or other chemical compounds to separate gold from unwanted materials. While effective, they require careful handling due to the hazardous nature of the chemicals involved. These machines are often favored when dealing with gold alloys that contain more complex impurities.

Portable Gold Refining Machines

For smaller operations or individuals looking to refine gold on a smaller scale, portable gold refining machines offer a convenient solution. These machines are easy to transport and set up, allowing users to refine gold in various locations. Despite their smaller size, they can still deliver high-purity results, making them a popular option for small businesses or hobbyists.

Choosing the Right Gold Refining Machine for Your Needs

Selecting the right gold refining machine depends on several factors, including the scale of operations, the desired level of purity, and the type of gold being processed. For industrial purposes, large machines with advanced technology are often necessary, while smaller operations can benefit from portable machines that offer flexibility.

Another important factor is the type of refining process preferred. If environmental impact is a concern, machines that use eco-friendly methods, such as electrolysis, may be the best choice. Additionally, ensuring that the machine can handle the desired volume of gold is crucial for efficient operation.

Maintenance of Gold Refining Machines

Regular maintenance is essential to keep a gold refining machine operating at peak efficiency. This includes cleaning the equipment, checking for wear and tear, and ensuring that all components are functioning properly. For machines that use chemical processes, special attention must be given to the handling and disposal of chemicals to prevent contamination or damage to the machine.

Operators should also ensure that the gold refining machine is regularly calibrated to maintain accuracy in the refining process. Periodic inspections can help identify potential issues early, preventing costly repairs or downtime.

Environmental Benefits of Modern Gold Refining Machines

One of the significant advancements in gold refining machines is the move toward more environmentally friendly practices. Traditional gold refining methods often involved hazardous chemicals that could harm the environment. Modern machines, especially those using electrolysis, are designed to minimize environmental impact by recycling by-products and reducing waste.

Some gold refining machines also have built-in systems to manage emissions, making them more compliant with environmental regulations. These machines not only help protect the environment but also provide cost savings through the reuse of materials and lower energy consumption.

Applications of a Gold Refining Machine

A gold refining machine is essential in various industries where gold purity is paramount. In the jewelry industry, high-quality gold is necessary to produce beautiful, durable pieces. The electronics industry also relies on gold with minimal impurities, as even slight contamination can affect the performance of electronic components.

Additionally, gold refined using a gold refining machine is favored by investors, as it holds a higher value due to its purity. The financial market places a premium on pure gold, making it a worthwhile investment for those looking to diversify their portfolios.

A gold refining machine is a crucial tool in achieving high-purity gold, whether for industrial applications, investment, or personal use. By understanding how these machines work and the types available, businesses and individuals can choose the best equipment for their needs. With advancements in technology and a focus on environmental sustainability, gold refining machines continue to play a vital role in the precious metals industry.