gold refining system

Understanding the Gold Refining System A Complete Guide

A gold refining system is essential for anyone involved in the business of purifying gold. Whether you are refining on a small scale for personal purposes or operating commercially, a gold refining system ensures that the gold you recover is of the highest purity. This article will explore what a gold refining system is, how it works, and the key components that make it effective.

What is a Gold Refining System?

A gold refining system is a combination of equipment, chemicals, and processes used to remove impurities from gold and recover it in its purest form. Gold refining can be done through various methods, such as chemical refining, melting, and smelting. Each method relies on different techniques and equipment but aims for the same outcome: high-purity gold that is free from contaminants.

These systems are designed to simplify the complex process of refining gold, allowing for efficiency, safety, and accuracy. Gold refining systems are used by both hobbyists and professionals to refine gold scrap, jewelry, and even gold ore.

Components of a Gold Refining System

A complete gold refining system includes several key components, each playing a specific role in the refining process. Below are the main components you’ll typically find in such a system.

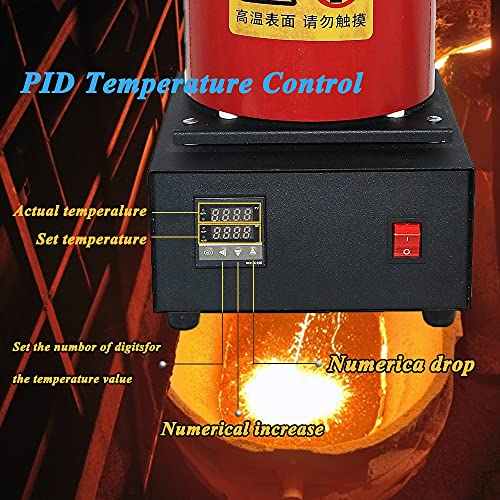

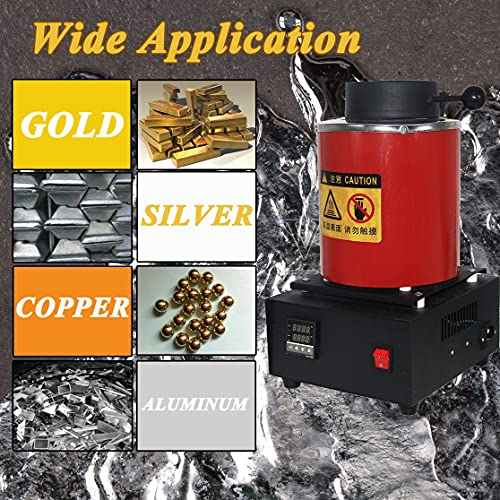

1. Gold Melting Furnace

A gold melting furnace is an essential part of any gold refining system. It is used to heat gold to its melting point, which is approximately 1,064°C (1,947°F). Furnaces come in different types, including electric, propane, and induction furnaces. The furnace allows for the gold to be melted down and separated from other metals or contaminants before further refining steps are applied.

2. Crucibles and Molds

Crucibles are used in conjunction with the furnace to hold the gold as it melts. They are made from heat-resistant materials, ensuring that they can withstand the high temperatures needed for melting gold. Once the gold is melted and impurities are removed, it can be poured into molds to create bars, coins, or other forms. Molds are also important in shaping the final refined gold product.

3. Chemical Solutions and Flux

Chemicals play a critical role in the refining system, especially when using chemical refining methods. Solutions like aqua regia (a mixture of hydrochloric and nitric acids) are often used to dissolve gold and separate it from other metals. Additionally, flux, which is a mixture of chemical agents such as borax and soda ash, is used to help remove impurities during the smelting process. These chemicals make it easier to extract and refine gold to its purest form.

4. Precipitation Equipment

In chemical refining systems, after the gold is dissolved in acid, it needs to be precipitated out of the solution. This step involves adding a precipitant, like sodium metabisulfite or urea, to cause the dissolved gold to solidify into particles. Precipitation equipment, such as filters and funnels, helps separate the solid gold from the liquid solution, making the recovery process easier and more efficient.

5. Gold Testing Kits

A vital part of any gold refining system is the testing of the refined gold to ensure it has reached the desired purity. Testing kits, including electronic gold testers and acid-based gold test kits, help assess the purity of the refined gold. The ability to verify gold purity is crucial for both professional refiners and hobbyists, as it confirms the success of the refining process.

Types of Gold Refining Systems

There are different types of gold refining systems available, each catering to different needs and scales of operation. Understanding the options can help determine which system is best for your refining needs.

1. Chemical Gold Refining Systems

Chemical refining is one of the most common methods used to purify gold. A chemical gold refining system uses acid solutions, such as aqua regia, to dissolve and purify gold. This method is highly effective and can achieve gold purity levels up to 99.99%. However, it requires careful handling of chemicals, as they can be hazardous to health and the environment.

Chemical refining systems are ideal for those working with scrap gold, jewelry, or small amounts of gold that need high-purity refinement. These systems are also widely used in commercial operations because of their precision and ability to handle larger quantities.

2. Electrolytic Gold Refining Systems

Electrolytic refining is another highly effective system for refining gold. In this method, gold is placed into an electrolyte solution, where it undergoes a chemical reaction that separates the pure gold from other metals and impurities. This method is widely used in industrial refining processes and is highly efficient, though it requires more complex equipment and precise control over the refining conditions.

3. Smelting Systems for Gold Refining

Smelting is a physical process used to separate gold from impurities using heat. A smelting system includes a furnace, crucibles, and flux, which work together to melt down the gold and remove other metals or contaminants. This system is less complicated than chemical methods and can be used by hobbyists or smaller refiners to achieve decent gold purity. However, smelting does not typically achieve the same level of purity as chemical methods.

Why a Gold Refining System is Important

Having a dedicated gold refining system is essential for ensuring that the refining process is efficient, accurate, and safe. Refining systems help eliminate human error and make it easier to achieve consistent results. They are designed to simplify the process and provide the necessary tools and equipment to handle gold refining effectively.

For professionals, a gold refining system is critical for meeting industry standards and ensuring that the gold meets purity requirements. For hobbyists or small-scale refiners, these systems make it possible to refine gold from scrap or other sources at home with a level of precision and safety that would otherwise be difficult to achieve.

Factors to Consider When Choosing a Gold Refining System

When selecting a gold refining system, several factors need to be considered to ensure it meets your specific needs:

- Scale of Operation: Are you refining gold on a small, medium, or large scale? Smaller systems are often sufficient for hobbyists, while larger systems are necessary for commercial operations.

- Type of Refining Method: Different systems are tailored for chemical, electrolytic, or smelting processes. Choose a system that aligns with your preferred refining method.

- Purity Requirements: If achieving 99.99% pure gold is a priority, chemical refining systems may be the best option. For less stringent purity needs, smelting systems may be more practical.

- Safety and Environmental Considerations: Handling chemicals and high temperatures requires proper safety equipment and procedures. Ensure the system you choose includes appropriate safety features and meets environmental standards.

A gold refining system is an essential investment for anyone involved in the process of purifying gold. From chemical refining systems to smelting setups, each method has its unique benefits and can be tailored to different refining needs. With the right equipment and techniques, you can ensure that the gold you refine is of the highest possible quality. Whether for personal or professional use, a gold refining system allows you to achieve consistent, safe, and efficient results, ensuring that your refined gold is ready for resale, investment, or manufacturing.