gold refining techniques

Gold Refining Techniques An Overview

Gold refining is the process of purifying raw gold to eliminate impurities and enhance its value. Throughout history, various gold refining techniques have been developed to extract pure gold from its ores and other materials. These methods have evolved over time, with some ancient techniques still in use today, alongside more modern, sophisticated processes.

Why Gold Refining Is Important

Refining gold is critical for both the mining industry and the precious metals market. Raw gold contains impurities such as silver, copper, and other base metals, which diminish its value. Gold refining techniques help to purify the gold to the highest possible standard, increasing its market worth and utility in various industries such as jewelry making, electronics, and investment products.

Traditional Gold Refining Techniques

Fire Assay

One of the oldest gold refining techniques is the fire assay method, which dates back to ancient times. This process involves melting the gold ore in a furnace and adding lead and silver to extract pure gold. The metal mixture is subjected to high heat, causing the impurities to separate. The pure gold is then retrieved from the molten mass. Although this method is still used today for small-scale refining, it is time-consuming and requires a great deal of skill.

Cupellation

Cupellation is another ancient gold refining technique used to purify gold. This process involves heating the gold in a furnace with a porous material called a cupel. The impurities in the gold, primarily base metals, oxidize and are absorbed by the cupel, leaving behind refined gold. This method is effective for removing lead and other base metals but may not produce the highest purity levels compared to modern methods.

Modern Gold Refining Techniques

With advancements in technology, modern gold refining techniques have become more efficient and capable of producing higher purity gold. These methods are used in both industrial and commercial settings to refine gold on a large scale.

Chemical Gold Refining

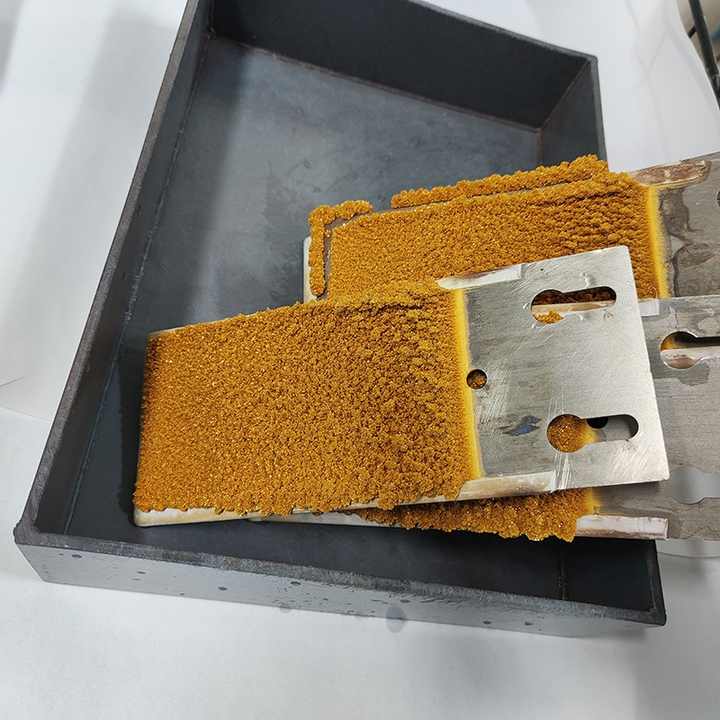

One of the most widely used modern gold refining techniques is chemical refining. This method involves dissolving the gold in a chemical solution, such as aqua regia, a mixture of nitric and hydrochloric acids. Once dissolved, the gold is separated from other materials in the ore. The gold is then precipitated out of the solution using a reducing agent like sodium metabisulfite or ferrous sulfate.

The chemical refining process is highly effective, capable of producing gold with purity levels of 99.9% or higher. It is widely used by major refineries worldwide and is considered one of the most reliable techniques for refining gold.

Electrolytic Refining

Electrolytic refining is another advanced gold refining technique used to achieve high purity levels. In this method, gold is dissolved in a solution of gold chloride, and an electric current is passed through the solution. The pure gold is deposited onto a cathode, while the impurities remain in the solution or collect on the anode.

Electrolytic refining is known for producing gold with exceptional purity, often reaching 99.99%. This method is favored by industries requiring highly pure gold, such as the electronics and aerospace sectors.

Comparison of Gold Refining Techniques

Each gold refining technique offers different advantages depending on the desired purity, scale of operation, and type of impurities present in the raw material. Traditional methods like fire assay and cupellation are ideal for small-scale refining, while modern techniques like chemical and electrolytic refining are preferred for larger operations and higher purity requirements.

| Technique | Purity Achieved | Scale of Operation | Efficiency |

|---|---|---|---|

| Fire Assay | Moderate | Small | Moderate |

| Cupellation | Moderate | Small | Moderate |

| Chemical Refining | High (99.9%) | Large | High |

| Electrolytic Refining | Very High (99.99%) | Large | Very High |

Environmental Considerations in Gold Refining

With the growing awareness of environmental impact, many refineries are adopting greener gold refining techniques. Traditional methods, such as fire assay and chemical refining, often involve hazardous chemicals and high energy consumption. In response, some refineries are shifting to cleaner processes that minimize environmental harm.

Bioleaching

Bioleaching is an emerging technique that uses bacteria to extract gold from its ore. This method is eco-friendly, as it reduces the need for toxic chemicals and high temperatures. While bioleaching is still in its early stages, it shows promise as a sustainable alternative to traditional gold refining methods.

Gold Refining in Industry Today

Today, gold refining techniques are used not only by large-scale mining companies but also by jewelers, investors, and hobbyists. Industrial refineries use advanced methods like chemical and electrolytic refining to produce gold for global markets. Smaller refiners and goldsmiths may still rely on more traditional methods for refining gold on a small scale.

The wide variety of gold refining techniques available today offers refiners the ability to choose the most appropriate method for their specific needs. From ancient methods like fire assay to cutting-edge technologies like electrolytic refining, each technique plays a crucial role in transforming raw gold into a valuable commodity. As technology advances and environmental considerations become more important, the industry will continue to evolve, seeking out cleaner and more efficient ways to refine gold.