gold silver smelting equipment

Essential Gold and Silver Smelting Equipment

Smelting is a critical process in the extraction of gold and silver from their ores, and having the right equipment is essential for achieving optimal results. Whether for small-scale operations or industrial-scale production, the right gold and silver smelting equipment can significantly impact efficiency, safety, and the quality of the final product. This article explores the various types of equipment used in the smelting of gold and silver, their functions, and considerations for selecting the right tools for your needs.

Overview of the Smelting Process

Before diving into the equipment, it is important to understand the smelting process itself. Smelting involves heating ore to high temperatures in the presence of a reducing agent, allowing the separation of valuable metals from impurities. This process not only concentrates the metals but also prepares them for further refining to achieve higher purity.

Key Smelting Equipment

The following types of equipment are commonly used in the smelting of gold and silver:

Furnaces

Furnaces are the heart of any smelting operation. They are responsible for providing the high temperatures necessary to melt the ores.

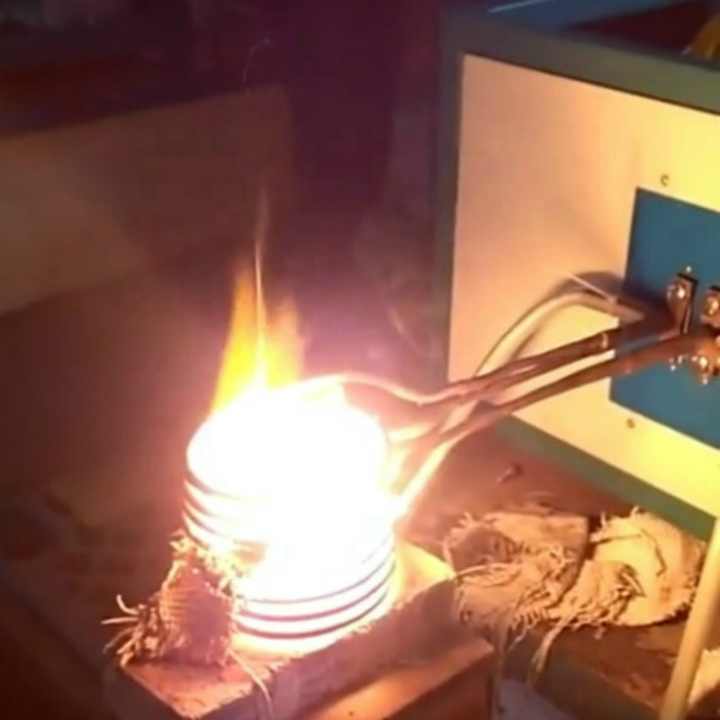

- Induction Furnaces: These furnaces use electromagnetic induction to generate heat. They are highly efficient and can quickly reach the required temperatures, making them ideal for small to medium-scale operations. Induction furnaces minimize oxidation and provide precise temperature control, essential for producing high-purity metals.

- Electric Arc Furnaces: Often used in industrial settings, electric arc furnaces create heat by passing an electric current through electrodes. They can handle larger quantities of ore and are capable of reaching extremely high temperatures, making them suitable for large-scale production.

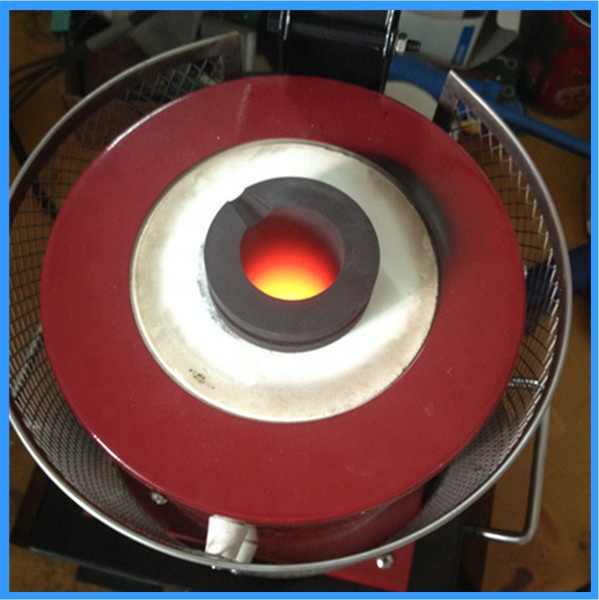

- Crucible Furnaces: These furnaces are typically used for small-scale operations or by hobbyists. They consist of a crucible that can be heated using various fuels, including propane or charcoal. Crucible furnaces are versatile and relatively inexpensive, making them accessible for smaller operations.

Crucibles

Crucibles are essential components of the smelting process. They are containers designed to withstand high temperatures and are used to hold the ore and flux during heating.

- Materials: Crucibles can be made from various materials, including graphite, ceramic, and fire clay. The choice of material depends on the specific smelting application and the temperatures involved. Graphite crucibles are popular for their high thermal conductivity and resistance to thermal shock.

Flux

Flux is a material added during the smelting process to help separate impurities from the metal. Common fluxes used in gold and silver smelting include borax, soda ash, and silica. The type of flux chosen can influence the efficiency of the smelting process and the quality of the final product.

Safety Equipment

Safety is paramount in smelting operations due to the high temperatures and potential hazards involved. Key safety equipment includes:

- Protective Gear: Operators should wear heat-resistant gloves, goggles, and protective clothing to shield against burns and exposure to harmful fumes.

- Ventilation Systems: Proper ventilation is crucial to prevent the accumulation of harmful gases released during the smelting process. Fume hoods and exhaust systems help ensure a safe working environment.

- Fire Extinguishing Equipment: Given the risk of fire, having appropriate fire extinguishing equipment readily available is essential for any smelting operation.

Considerations for Choosing Equipment

When selecting gold and silver smelting equipment, several factors should be taken into account:

- Scale of Operation: Determine whether the operation will be small-scale or industrial. This decision will influence the type and size of the equipment needed.

- Purity Requirements: If high-purity gold and silver are a priority, investing in advanced furnaces that offer precise temperature control may be necessary.

- Budget: Evaluate the budget for purchasing equipment. While some furnaces and tools may have higher upfront costs, they may provide better efficiency and return on investment over time.

- Space: Consider the available space for setting up the equipment. Some furnaces require more room than others, and it is crucial to ensure that the workspace can accommodate the equipment safely.

Gold and silver smelting equipment is vital for efficiently extracting and refining these precious metals. Understanding the different types of furnaces, crucibles, fluxes, and safety equipment available will help operators make informed decisions to optimize their smelting processes. With the right equipment in place, the journey from ore to pure metal can be both efficient and safe, ensuring high-quality results that meet industry standards. As technology continues to evolve, staying informed about advancements in smelting equipment will enhance productivity and sustainability in gold and silver refining operations.