Gold Smelting And Refining Process

Gold Smelting And Refining Process: A Comprehensive Guide by FRT Machinery

Understanding the Basics of Gold Smelting And Refining Process

Gold smelting and refining process is a sophisticated method used to extract and purify gold from raw ore. This process involves several steps that ensure the removal of impurities, leaving behind pure gold. For manufacturers and artisans alike, understanding the intricacies of this process is essential for achieving high-quality results. FRT Machinery, a leading provider of smelting and refining equipment, offers insights into the key stages of gold smelting and refining.

Preparing the Ore for Gold Smelting And Refining Process

Before the actual smelting begins, it’s crucial to prepare the ore properly. This preparation includes crushing and grinding the ore into fine particles, which increases its surface area and facilitates more efficient smelting. FRT Machinery’s advanced crushers and grinders are designed to handle large volumes of ore while maintaining optimal particle size distribution, ensuring that each piece of ore is ready for the next phase of the gold smelting and refining process.

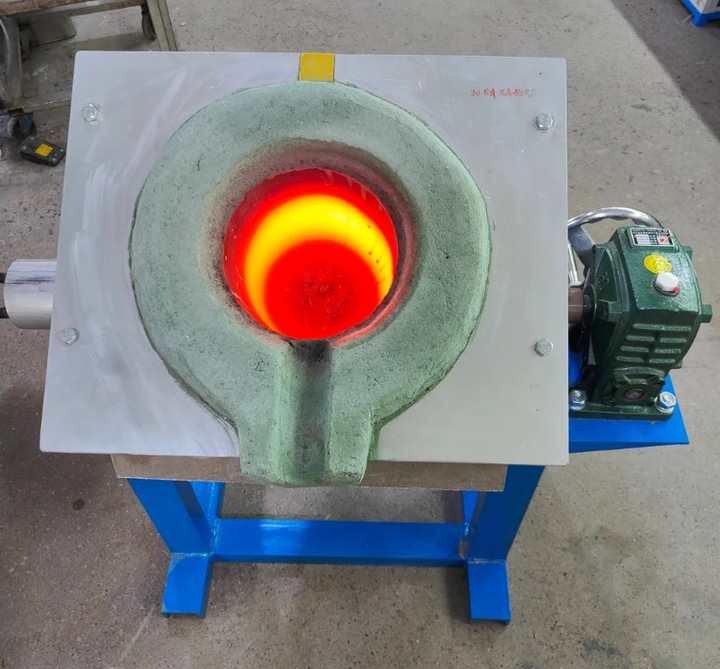

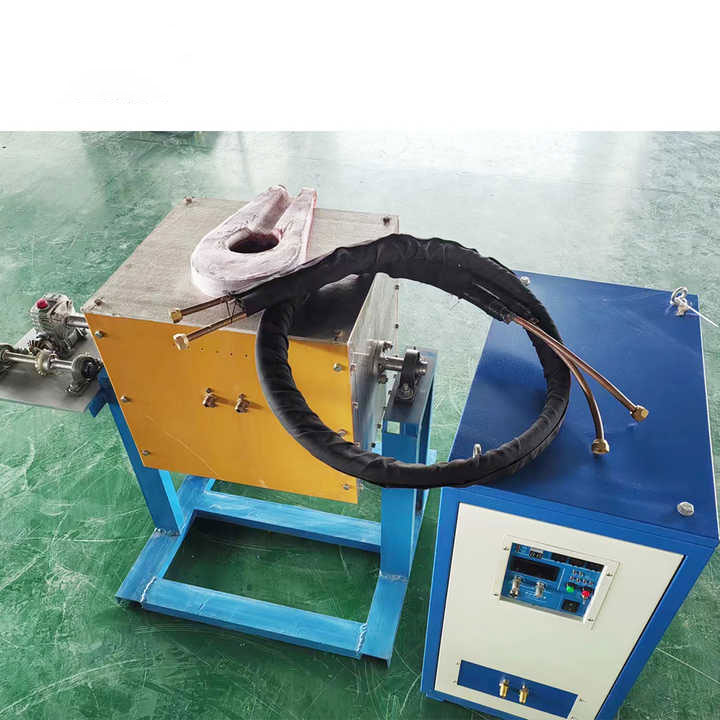

The Crucial Step of Melting in the Gold Smelting And Refining Process

Melting is a critical step in the gold smelting and refining process where the prepared ore is heated until it liquefies. FRT Machinery’s state-of-the-art furnaces provide uniform heat distribution, enabling the ore to melt efficiently without losing its valuable components. Once melted, additives like fluxes are introduced to help separate the gold from other metals and impurities present in the ore.

Utilizing Fluxes During the Gold Smelting And Refining Process

Fluxes play a vital role in the separation of gold from non-metallic materials during the smelting process. These chemical agents combine with impurities to form slag, which can be easily removed from the molten gold. FRT Machinery recommends specific types of fluxes based on the composition of the ore being processed, ensuring maximum efficiency and purity of the final product.

Purification Techniques in the Gold Smelting And Refining Process

After the initial smelting, further purification techniques are employed to refine the gold to its highest purity level. Electrolysis and chemical leaching are common methods used in this stage. FRT Machinery provides specialized equipment for these processes, ensuring that all remaining impurities are eliminated, resulting in 99.99% pure gold. These advanced purification techniques are crucial for industries requiring ultra-pure gold, such as electronics and jewelry making.

Safety Measures in the Gold Smelting And Refining Process

Safety is paramount in any industrial process, especially one involving high temperatures and potentially hazardous chemicals. FRT Machinery emphasizes the importance of adhering to strict safety protocols throughout the gold smelting and refining process. This includes the use of protective gear, proper ventilation systems, and regular maintenance checks on all machinery. By prioritizing safety, FRT Machinery helps ensure a secure working environment for all personnel involved in the process.

Conclusion: The Future of Gold Smelting And Refining Process

As technology advances, so too does the gold smelting and refining process. FRT Machinery is committed to developing innovative solutions that enhance efficiency, improve safety standards, and reduce environmental impact. By staying at the forefront of technological advancements, FRT Machinery aims to support the growth and sustainability of the gold industry for years to come. Whether you’re a small-scale artisan or a large industrial operation, investing in modern smelting and refining technologies from FRT Machinery can significantly impact your production capabilities and product quality.