gold smelting companies

A Comprehensive Overview of Gold Smelting Companies

Gold smelting is an integral part of the gold refining industry, where raw gold is processed to remove impurities and convert it into pure, usable metal. Gold smelting companies play a crucial role in this process, offering specialized services and equipment to ensure that the smelting is done efficiently and effectively. This article provides an in-depth look at the operations of gold smelting companies, the services they offer, and their significance in the global gold market.

The Role of Gold Smelting Companies in the Industry

Gold smelting companies are responsible for the critical task of transforming raw gold ore or scrap gold into refined gold bars or other forms of pure gold. These companies typically operate large-scale smelting facilities equipped with advanced technology and machinery to achieve high levels of purity.

How Gold Smelting Companies Operate

The operation of gold smelting companies involves several key processes, including the acquisition of raw materials, smelting, refining, and distribution of the final product. These companies often work closely with mining firms, recycling companies, and other stakeholders to source gold that can be smelted and refined.

Sourcing Raw Materials

Gold smelting companies acquire raw materials from various sources, including gold mines, scrap gold, and other recyclable gold products. The quality and purity of the raw materials directly impact the efficiency and effectiveness of the smelting process.

Smelting and Refining

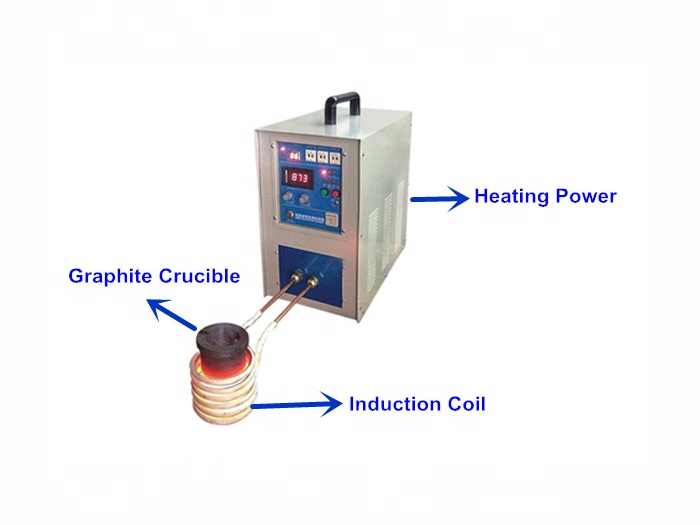

The smelting process involves heating the gold ore or scrap to high temperatures to separate the gold from other metals and impurities. This is followed by refining, which further purifies the gold to meet industry standards. Smelting companies utilize various techniques, including traditional fire-based smelting and modern methods like induction melting, to achieve the desired results.

Distribution of Refined Gold

Once the gold has been refined, it is cast into bars, coins, or other forms and distributed to various markets. Gold smelting companies often supply their products to banks, jewelers, investment firms, and industrial users.

The Importance of Quality Control in Gold Smelting Companies

Quality control is a top priority for gold smelting companies. Ensuring that the gold produced meets the highest standards of purity is essential for maintaining the company’s reputation and meeting the needs of its customers.

Techniques for Ensuring High Purity

Gold smelting companies employ various techniques to ensure that the gold they produce is of the highest purity. These techniques include careful selection of raw materials, precise control of smelting temperatures, and the use of advanced refining processes.

Selection of Raw Materials

Choosing high-quality raw materials is the first step in producing pure gold. Gold smelting companies work closely with suppliers to ensure that the ore or scrap they receive is free from excessive impurities.

Temperature Control in Smelting

Controlling the temperature during the smelting process is critical for separating gold from other metals and impurities. Gold smelting companies use sophisticated equipment to monitor and adjust temperatures to achieve optimal results.

Advanced Refining Processes

After smelting, the gold undergoes further refining to remove any remaining impurities. This may involve processes like electrolysis, chemical treatment, or additional smelting, depending on the desired level of purity.

Testing and Verification

Once the gold has been refined, it undergoes rigorous testing to verify its purity. Gold smelting companies use techniques like X-ray fluorescence (XRF) and fire assay to ensure that the final product meets industry standards.

Innovations in the Gold Smelting Industry

The gold smelting industry has seen significant technological advancements in recent years, with companies investing in new equipment and processes to improve efficiency and reduce environmental impact.