Gold Smelting Furnaces

Understanding the Precision of Gold Smelting Furnaces by FRT Machinery

Gold smelting furnaces are essential tools in the precious metals industry, enabling the extraction and purification of gold from its ore. These furnaces have evolved significantly over time, incorporating advanced technologies to enhance efficiency and reduce environmental impact. As experts in manufacturing high-quality industrial machinery, FRT Machinery offers a range of gold smelting furnaces designed for both small-scale and large-scale operations.

The Role of Temperature Control in Gold Smelting Furnaces

Temperature control is one of the most critical aspects of operating a gold smelting furnace effectively. Precise temperature regulation ensures that the gold melts at the optimal point without causing unnecessary oxidation or loss. FRT Machinery’s furnaces feature state-of-the-art heating elements and insulation materials that maintain consistent temperatures, even during prolonged smelting sessions. This stability is crucial for achieving high purity levels in the final product.

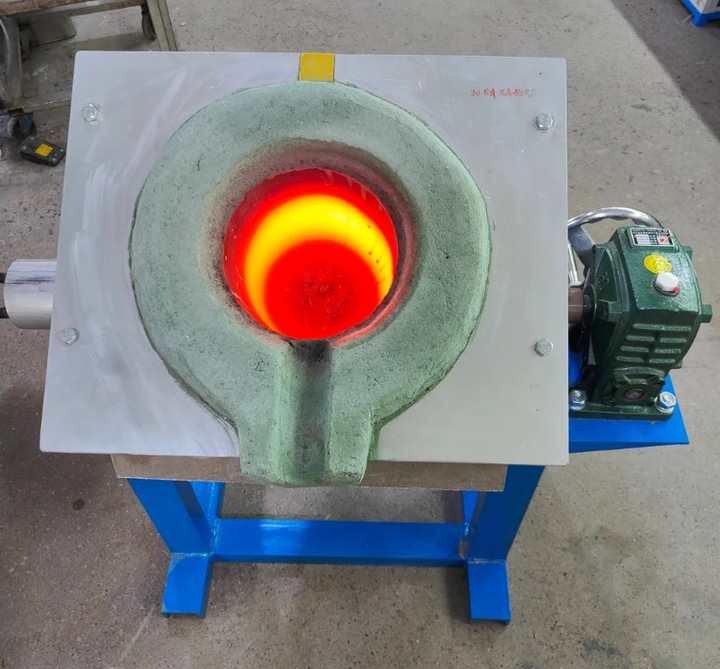

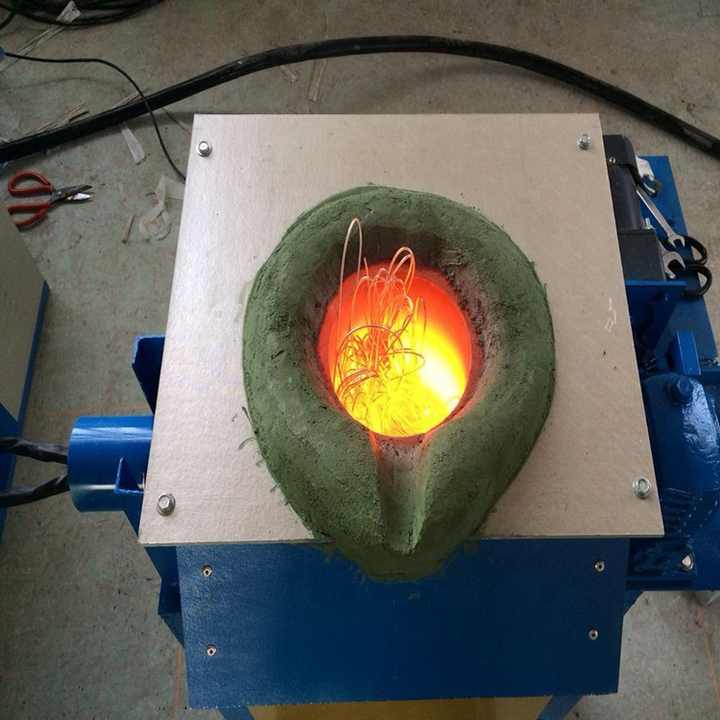

Innovative Design Features of Gold Smelting Furnaces

FRT Machinery prides itself on innovative design features that set our gold smelting furnaces apart from competitors. One such feature is the tilting mechanism, which allows for easy and safe pouring of molten gold into molds. Additionally, the compact design of these furnaces makes them suitable for various settings, from small artisanal workshops to large industrial complexes. Each unit is built with durability in mind, ensuring long-lasting performance under demanding conditions.

Safety Protocols in Operating Gold Smelting Furnaces

Safety is paramount when dealing with high-temperature processes like gold smelting. FRT Machinery integrates multiple safety protocols into its furnaces to protect operators and ensure compliance with industry standards. These include automatic shut-off systems, heat-resistant handles, and clear viewing windows for monitoring the smelting process without direct exposure to heat. Training programs provided by FRT Machinery also emphasize best practices for maintaining a safe working environment.

Eco-Friendly Practices in Modern Gold Smelting Furnaces

Environmental sustainability has become increasingly important in all industries, including gold smelting. FRT Machinery’s commitment to eco-friendly practices is reflected in the design of its furnaces, which utilize energy-efficient technologies to minimize fuel consumption and reduce emissions. By adopting these green solutions, operators can significantly lower their carbon footprint while still achieving top-notch smelting results.

Maintenance Requirements for Gold Smelting Furnaces

Regular maintenance is key to prolonging the lifespan of a gold smelting furnace and maintaining its peak performance. FRT Machinery provides comprehensive guidelines on routine checks and maintenance procedures tailored specifically for our range of furnaces. From cleaning the combustion chamber to inspecting electrical connections, these steps help identify potential issues early on, preventing costly breakdowns and downtime.

Customization Options for Gold Smelting Furnaces

Recognizing that every operation has unique needs, FRT Machinery offers customization options for its gold smelting furnaces. Whether it’s adjusting the size, modifying the fuel type, or adding specialized features, we work closely with clients to tailor solutions that perfectly match their specific requirements. This flexibility ensures that each furnace operates at maximum efficiency within its designated setting, contributing to overall productivity gains.

By investing in FRT Machinery’s gold smelting furnaces, businesses can benefit from advanced technology, reliable performance, and unparalleled support—all designed to drive success in today’s competitive mining sector.