gold smelting process

Introduction to the Gold Smelting Process

The gold smelting process is a fundamental method used to extract and refine gold from its ore. This process, which has been practiced for centuries, involves the use of high temperatures and chemical agents to remove impurities and produce pure gold. Understanding the gold smelting process is key for those involved in mining, refining, or investing in gold, as it is the step that transforms raw material into valuable, refined metal.

Steps Involved in the Gold Smelting Process

The gold smelting process begins by mining raw gold ore from the earth. This ore typically contains other metals, such as silver and copper, along with non-metallic impurities. The first step in the process is crushing and grinding the ore to increase the surface area and make it easier to extract the gold. Once the ore is broken down, it is ready for smelting.

Melting the Ore to Extract Gold

At the heart of the gold smelting process is the melting phase. In this stage, the crushed ore is placed into a furnace, which is heated to temperatures exceeding 1,000 degrees Celsius. At this extreme heat, the gold inside the ore melts, separating from the surrounding rock and other metals. This is the point at which the gold begins to transition from its raw form to a more refined state.

The Role of Flux in the Gold Smelting Process

An essential component of the gold smelting process is the use of flux. Flux is a chemical substance that helps to separate impurities from the molten gold. Commonly used flux materials include borax, silica, and sodium nitrate. These chemicals bind with impurities such as dirt and other metals, forming a slag that floats on the surface of the molten gold. This slag can then be easily removed, leaving behind purer gold.

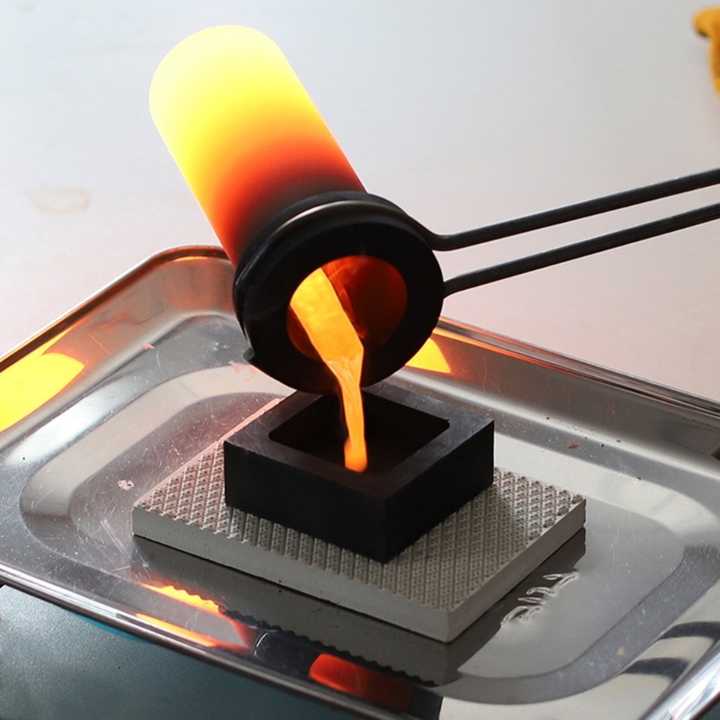

Cooling and Solidifying the Gold

Once the molten gold is free from most of its impurities, it is poured into molds to cool and solidify. As the gold cools, it takes the shape of bars or ingots. These gold bars are not yet fully pure, but they are significantly cleaner than the raw ore. Further refining processes may be necessary to achieve the desired level of purity, depending on the intended use of the gold.

Refining After the Smelting Process

While the gold smelting process removes many impurities, it is often followed by a refining stage to achieve higher purity. Refining techniques such as electrolysis or chemical methods can remove even trace impurities, resulting in gold that is 99.9% pure. This is especially important for gold used in jewelry, electronics, and financial markets, where the highest level of purity is required.

Gold Smelting vs. Gold Refining

It is important to differentiate between gold smelting and gold refining. Smelting is the process of using heat to extract gold from its ore and remove larger impurities. Refining, on the other hand, focuses on removing the last traces of impurities to produce highly pure gold. Both processes are critical in transforming raw gold into a usable product.

Environmental and Safety Considerations

The gold smelting process has environmental and safety implications. The high temperatures required for smelting can result in energy consumption, while the use of chemicals in flux can pose risks if not handled properly. Furthermore, emissions from smelting plants can contribute to air pollution. As a result, modern gold smelting operations are adopting greener technologies, such as advanced filtration systems and energy-efficient furnaces, to mitigate these concerns.

Technological Advances in the Gold Smelting Process

Recent advancements in technology have made the gold smelting process more efficient and environmentally friendly. New furnace designs allow for greater temperature control and reduced energy usage. In addition, innovations in flux formulations have improved the removal of impurities, leading to higher purity levels in the final product. These technological improvements have made gold smelting safer, faster, and more cost-effective.

The gold smelting process is a crucial step in the journey from raw gold ore to refined metal. It involves a series of carefully controlled stages, including melting, the use of flux, and cooling, to remove impurities and produce gold that is suitable for further refining or direct use. As technology continues to advance, the gold smelting process is becoming more efficient and environmentally conscious, ensuring that gold remains one of the most valuable and sought-after metals in the world.