in the refining of silver

Understanding the Process in the Refining of Silver

In the refining of silver, various techniques are employed to transform raw silver ore or impure silver into a purer and more usable form. Silver is often found mixed with other metals and impurities, so refining is essential to achieve the desired level of purity. This article delves into the steps and methods involved in the refining of silver, focusing on both traditional and modern approaches used to achieve high-quality, pure silver.

The Importance of Refining Silver

Silver is a valuable metal used in various industries, from jewelry and electronics to photography and medicine. In its raw form, silver extracted from mines or recycled products contains impurities and other metals that must be removed. The refining process purifies the silver, making it suitable for industrial and commercial applications. In the refining of silver, achieving purity levels of up to 99.9% is often required for specific uses, such as in electronics where high conductivity is crucial.

Key Steps in the Refining of Silver

Mining and Ore Extraction

Before refining can begin, the silver must first be extracted from its ore. Silver is commonly found in mineral ores such as argentite and galena, often alongside other metals like lead, zinc, or copper. In the mining process, these ores are brought to the surface and prepared for refining through crushing and grinding to release the silver from its surrounding material.

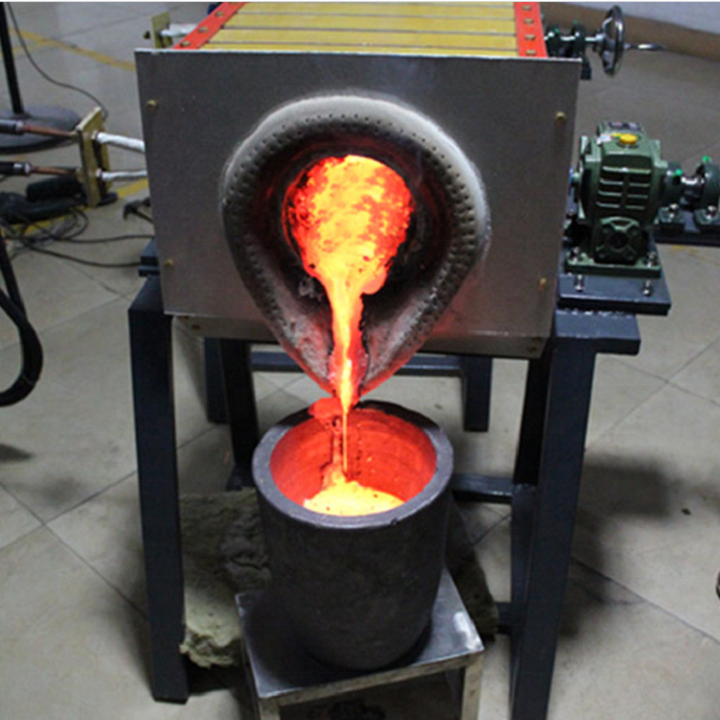

Smelting the Silver Ore

One of the initial steps in the refining of silver is smelting. Smelting is a process that involves melting the ore at high temperatures to separate silver from other metals and impurities. The ore is placed in a furnace along with a flux, which helps bind the impurities and allows the silver to separate. The result is a molten silver alloy that still contains trace amounts of other elements like lead or copper.

Cupellation: A Traditional Refining Method

After smelting, the silver still contains some impurities that need to be removed. Cupellation is an ancient method used in the refining of silver to further purify the metal. In this process, the silver alloy is placed in a special furnace and heated to extremely high temperatures. The lead and other non-precious metals oxidize and are absorbed by a porous material called a cupel. What remains is purified silver, which is then ready for further use.

Electrolytic Refining: Achieving High Purity

For silver that needs to meet exceptionally high purity standards, electrolytic refining is often employed. In the refining of silver using this method, an electrolyte solution is created by dissolving the impure silver in an acid, typically nitric acid. An electric current is passed through the solution, causing pure silver to accumulate on the cathode, while impurities either remain in the solution or fall to the bottom as sludge.

This method can produce silver with a purity level of 99.9%, which is often required for specific applications like fine jewelry and electronic components. The sludge, which may contain valuable metals like gold, can also be processed to recover these materials.

Chemical Refining: An Alternative Approach

Another method used in the refining of silver is chemical refining. This process involves dissolving silver in an acid to create a silver nitrate solution. The impurities are filtered out, and pure silver is recovered through precipitation using a reducing agent such as copper or zinc. The precipitated silver is then melted and cast into bars or ingots, achieving a high level of purity.

Modern Innovations in Silver Refining

While traditional methods like cupellation and smelting are still used, modern advancements in technology have led to more efficient and environmentally friendly techniques in the refining of silver. Automated refining equipment and more sustainable chemicals have helped reduce the environmental impact of silver refining. For instance, advanced filtration systems now capture toxic emissions, while energy-efficient furnaces lower the carbon footprint of the smelting process.

Applications of Refined Silver

Once the refining process is complete, the pure silver is used in a wide range of industries. Some of the primary uses of refined silver include:

- Jewelry: Silver’s luster and malleability make it a popular material for crafting fine jewelry.

- Electronics: Silver’s excellent conductivity is crucial in the manufacturing of electronic devices, including smartphones, computers, and televisions.

- Medical Equipment: Silver’s antimicrobial properties are used in medical instruments and devices.

- Coins and Bullion: Many investors prefer silver bullion and coins as a form of wealth preservation.

Environmental Considerations in Silver Refining

In the refining of silver, there are several environmental concerns that need to be addressed, particularly with regard to emissions from smelting and the use of toxic chemicals. Modern refineries have implemented stricter regulations and cleaner technologies to minimize their impact on the environment. Recycling silver from old electronics and industrial byproducts has also become a common practice, reducing the need for mining and lowering the overall environmental footprint of the refining process.

Challenges in the Refining of Silver

Despite the advancements in technology, refining silver still poses several challenges. One of the key difficulties lies in the removal of other precious metals, like gold or platinum, that may be present in the ore. Additionally, achieving extremely high levels of purity requires precise control over temperature, chemicals, and other refining parameters, making it a time-consuming and costly endeavor. Nonetheless, as demand for high-purity silver continues to grow, refiners are constantly seeking new methods to improve efficiency and reduce costs.

In the refining of silver, various processes are employed to remove impurities and produce high-quality, pure silver. From traditional methods like cupellation and smelting to modern techniques like electrolytic refining, each step plays a vital role in transforming raw silver into a valuable commodity. With continued advancements in technology and growing environmental awareness, the silver refining industry is poised to become even more efficient and sustainable in the years to come.