Melting And Refining Silver

Melting and Refining Silver: A Comprehensive Guide

When it comes to precious metals, silver holds a special place in both industry and art. Its versatility, conductivity, and beauty make it indispensable across various sectors. However, the process of transforming raw silver into a refined form ready for use is intricate and requires specialized knowledge and equipment. FRT Machinery, a leader in metallurgical solutions, offers insights into the key stages of melting and refining silver, ensuring purity and efficiency every step of the way.

Melting Silver: The Initial Step

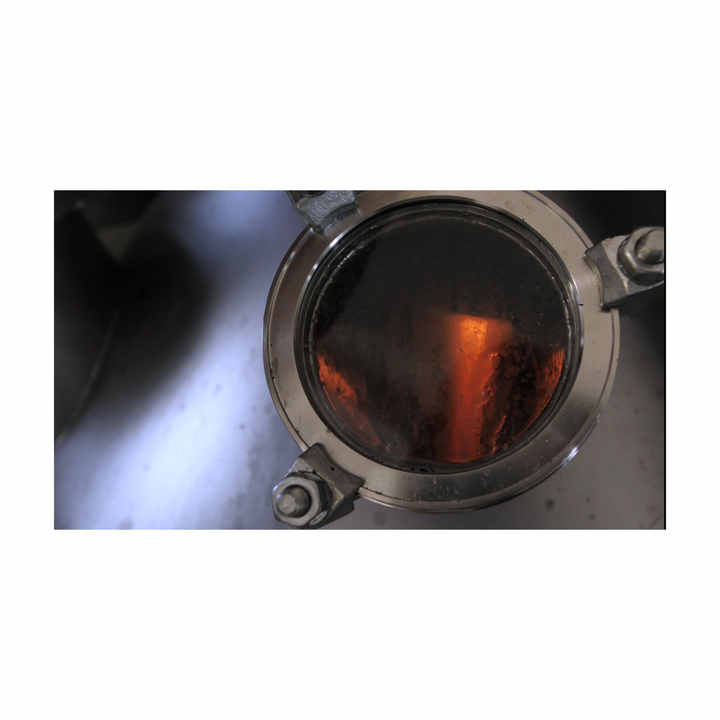

Melting silver is the first crucial stage in preparing this metal for further refinement. This process involves heating silver to its melting point—961.93°C (1763.5°F)—under controlled conditions using high-quality furnaces designed by FRT Machinery. Proper melting ensures that all impurities can be more effectively removed during subsequent refining processes. The choice of furnace depends on factors such as batch size, production rate, and desired final product quality.

Refining Silver: Removing Impurities

Once melted, silver enters the refining phase where it undergoes purification. FRT Machinery’s advanced refining techniques focus on eliminating contaminants through electrolysis or chemical methods. Electrolytic refining, for instance, involves passing an electric current through molten silver, causing impurities to settle at the bottom as sludge while pure silver plates out at the cathode. This method achieves exceptional purity levels, typically over 99.9%.

Silver Melting Equipment by FRT Machinery

To achieve optimal results in melting and refining silver, utilizing the right equipment is essential. FRT Machinery specializes in designing and manufacturing state-of-the-art furnaces and refining systems tailored to meet specific needs. Our range includes induction furnaces, which provide uniform heating and easy temperature control, ideal for melting operations. Additionally, we offer customized solutions for electrolytic refining setups, ensuring maximum efficiency and minimal environmental impact.

Benefits of Efficient Silver Refining

Efficient refining of silver not only enhances its purity but also contributes significantly to cost savings and sustainability efforts. By recovering valuable metals from scrap or recycled materials, industries can reduce their reliance on primary mining resources. Furthermore, advanced refining technologies from FRT Machinery minimize energy consumption and waste production, aligning with global environmental standards and promoting a circular economy within the silver processing industry.

Quality Assurance in Silver Refining

Ensuring the highest quality in silver refining requires rigorous testing and inspection procedures. FRT Machinery supports clients with comprehensive quality assurance protocols, including spectroscopic analysis to verify elemental composition and purity levels. These measures guarantee that refined silver meets international standards, making it suitable for applications ranging from jewelry making to electronic components.

Innovations in Silver Melting and Refining

Continuous innovation drives advancements in silver melting and refining technologies. FRT Machinery invests heavily in research and development to introduce cutting-edge solutions that address evolving market demands. From developing more efficient melting processes to improving recovery rates of precious metals from waste streams, our commitment to innovation ensures that we remain at the forefront of sustainable metallurgy practices.

By understanding the nuances of melting and refining silver, along with leveraging advanced machinery and methodologies provided by FRT Machinery, businesses can unlock new opportunities while maintaining high standards of quality and sustainability. Whether you’re looking to upgrade your existing setup or establish a new facility focused on silver processing, partnering with FRT Machinery will equip you with the tools necessary for success in today’s competitive landscape.