precious metal smelting equipment

Precious metal smelting equipment is essential for the refining and processing of valuable metals such as gold, silver, and platinum. This equipment facilitates the extraction of pure metals from ores and scrap materials, making it a cornerstone of the precious metal industry. This article explores the different types of smelting equipment, their functions, and best practices for their use.

The Importance of Precious Metal Smelting Equipment

Precious metal smelting equipment plays a crucial role in transforming raw materials into high-purity metals. Its importance can be understood through the following aspects:

Efficient Metal Extraction

Smelting equipment is designed to efficiently extract metals from ores and scrap. This process involves melting the materials at high temperatures to separate the metal from impurities.

Enhanced Purity

High-quality smelting equipment ensures that the final product is of high purity, meeting industry standards and specifications. This is vital for applications in jewelry, electronics, and investment.

Support for Various Metal Types

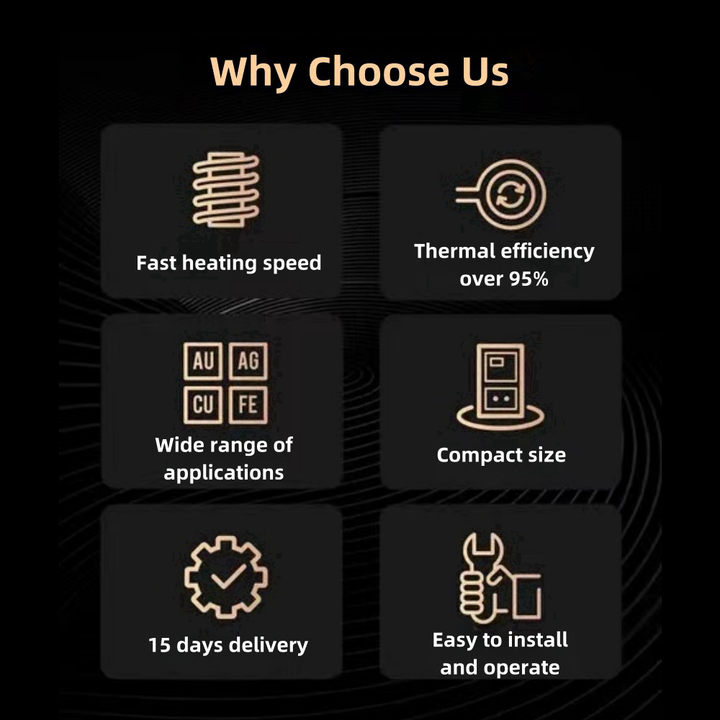

Smelting equipment can handle various types of precious metals, including gold, silver, and platinum. Different metals require specific equipment and processes for optimal results.

Versatility

Modern smelting equipment is versatile, allowing for the processing of different metals using adjustable settings and configurations. This flexibility makes it suitable for diverse applications.

Types of Precious Metal Smelting Equipment

Understanding the types of precious metal smelting equipment available can help in selecting the right tools for specific needs. Here are some common types:

Electric Furnaces

Electric furnaces are widely used in precious metal smelting due to their precision and efficiency. They use electrical energy to generate the high temperatures required for melting metals.

Arc Furnaces

Arc furnaces use electrical arcs to produce intense heat. They are commonly used for large-scale operations and can handle high volumes of material.

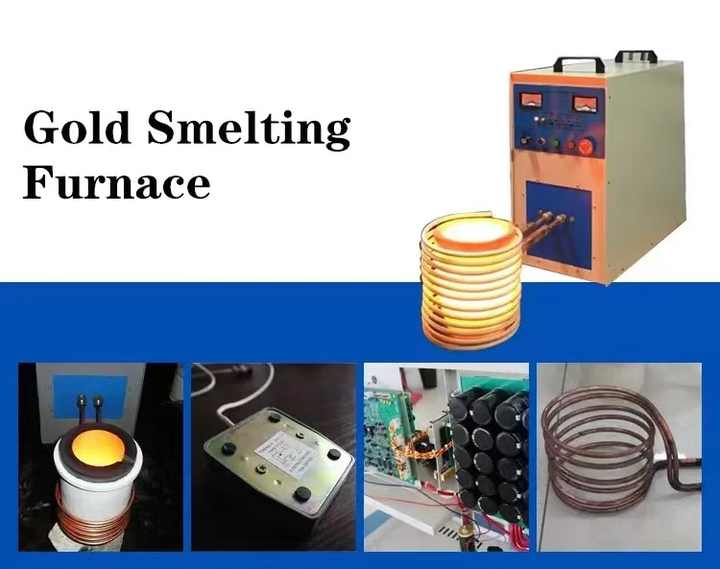

Induction Furnaces

Induction furnaces utilize electromagnetic induction to heat the metal. They are known for their energy efficiency and precise temperature control, making them ideal for smaller-scale operations.

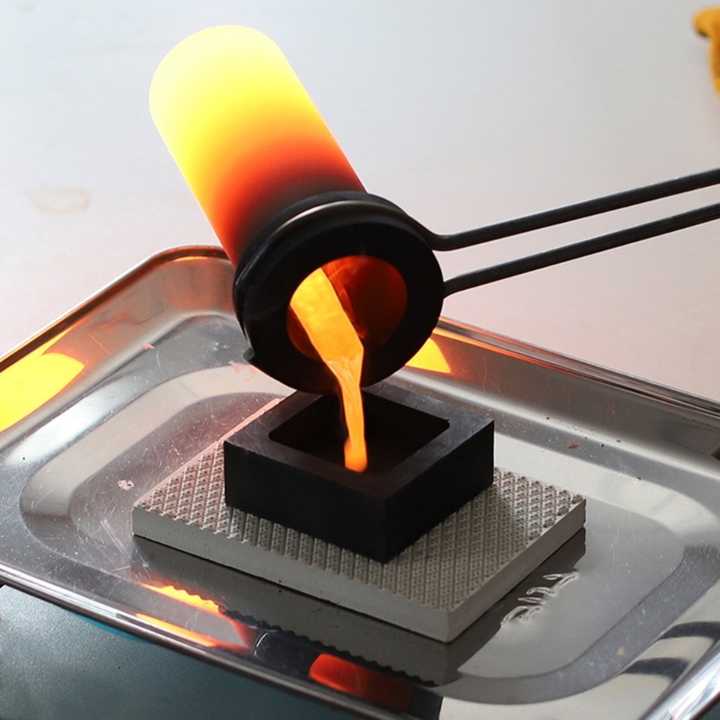

Crucibles

Crucibles are containers used to hold the metal during the smelting process. They must withstand extreme temperatures and resist chemical reactions with molten metal.

Graphite Crucibles

Graphite crucibles are popular for smelting precious metals due to their high thermal conductivity and resistance to molten metals.

Ceramic Crucibles

Ceramic crucibles are also used for high-temperature smelting. They are suitable for specific applications where graphite may not be ideal.

Electrodes

Electrodes are essential for conducting electrical energy into the furnace. They play a crucial role in maintaining a steady supply of electricity during the smelting process.

Graphite Electrodes

Graphite electrodes are commonly used due to their ability to withstand high temperatures and conduct electricity efficiently.

Metal Electrodes

Metal electrodes can be used depending on the specific requirements of the smelting process and the type of metal being processed.

Best Practices for Using Precious Metal Smelting Equipment

To achieve the best results with precious metal smelting equipment, certain best practices should be followed. These practices ensure efficient operation and high-quality results.

Regular Maintenance

Regular maintenance of smelting equipment is crucial for its longevity and performance. This includes:

Inspecting and Replacing Parts

Regularly inspect critical components, such as electrodes and crucibles, for wear and damage. Replace parts as needed to prevent equipment failure.

Cleaning Equipment

Clean the equipment thoroughly after each use to prevent contamination and ensure optimal performance in subsequent operations.

Monitoring the Smelting Process

Proper monitoring of the smelting process helps achieve desired results and maintain equipment efficiency.

Temperature Control

Ensure accurate temperature control during the smelting process. Use reliable temperature measurement tools to avoid fluctuations and achieve consistent results.

Process Adjustment

Adjust the equipment settings as needed based on the type of metal and desired purity. This may involve changing furnace temperatures, fluxes, or other parameters.

Ensuring Safety

Safety is paramount when operating smelting equipment. Follow these safety guidelines to protect yourself and others:

Using Protective Gear

Wear appropriate protective gear, including heat-resistant gloves, safety goggles, and protective clothing. This helps prevent injuries from high temperatures and molten metal.

Adhering to Safety Protocols

Follow established safety protocols and procedures to minimize the risk of accidents and ensure a safe working environment.

Innovations in Precious Metal Smelting Equipment

The field of precious metal smelting continues to evolve, with new innovations enhancing equipment performance and efficiency. Key developments include:

Automation and Control Systems

Modern smelting equipment often incorporates automation and control systems. These systems improve precision, efficiency, and ease of operation by automating various aspects of the smelting process.

Automated Furnaces

Automated furnaces provide precise control over temperature and other parameters, reducing the need for manual adjustments and improving consistency.

Advanced Monitoring

Advanced monitoring systems offer real-time data on the smelting process, allowing for better control and early detection of issues.

Energy Efficiency

New advancements focus on improving the energy efficiency of smelting equipment. This includes:

High-Efficiency Furnaces

High-efficiency furnaces use less energy while maintaining optimal performance. They help reduce operational costs and environmental impact.

Waste Heat Recovery

Some modern smelting equipment incorporates waste heat recovery systems, capturing and reusing heat that would otherwise be lost. This enhances overall energy efficiency.

Precious metal smelting equipment is essential for refining and processing valuable metals, ensuring high purity and quality. By understanding the types of equipment available, best practices for operation, and recent innovations, you can make informed decisions and achieve optimal results in precious metal processing. Whether for industrial applications or smaller-scale projects, investing in the right smelting equipment can significantly impact the efficiency and effectiveness of your operations.