precious metal smelting

Precious metal smelting is a vital process in the extraction and refinement of metals like gold, silver, platinum, and palladium. This procedure is crucial for producing high-purity metals that are used in various industries, including jewelry, electronics, and investment. In this article, we will explore the process of precious metal smelting, the techniques involved, and the significance of this process in different applications.

What is Precious Metal Smelting?

Precious metal smelting is the process of extracting valuable metals from their ores by applying heat and a reducing agent to decompose the ore, drive off other elements as gases or slag, and leave behind the pure metal. This process is essential for separating precious metals from impurities and other non-metallic elements found in raw ore. The smelting process is a fundamental step in the production of high-quality metals that meet industry standards for purity and performance.

The Precious Metal Smelting Process

The smelting process involves several stages, each designed to extract and purify precious metals from their ores. Below, we break down the key steps in the precious metal smelting process.

1. Ore Preparation and Concentration

Before smelting can begin, the ore must be prepared and concentrated. This involves crushing the ore to a fine powder to increase its surface area, making it easier to extract the metal during smelting. After crushing, the ore undergoes concentration, where the valuable metal particles are separated from the waste material. Techniques such as gravity separation, flotation, and magnetic separation are commonly used to concentrate the ore.

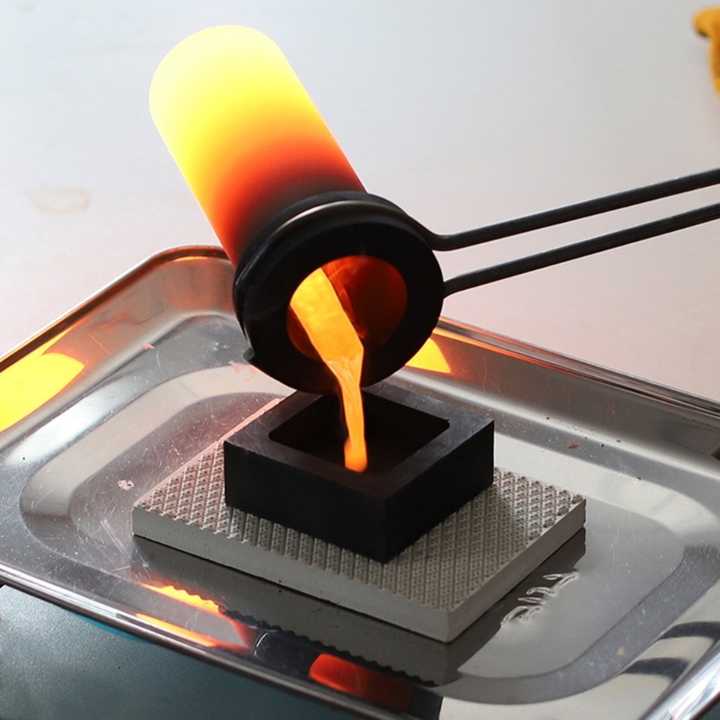

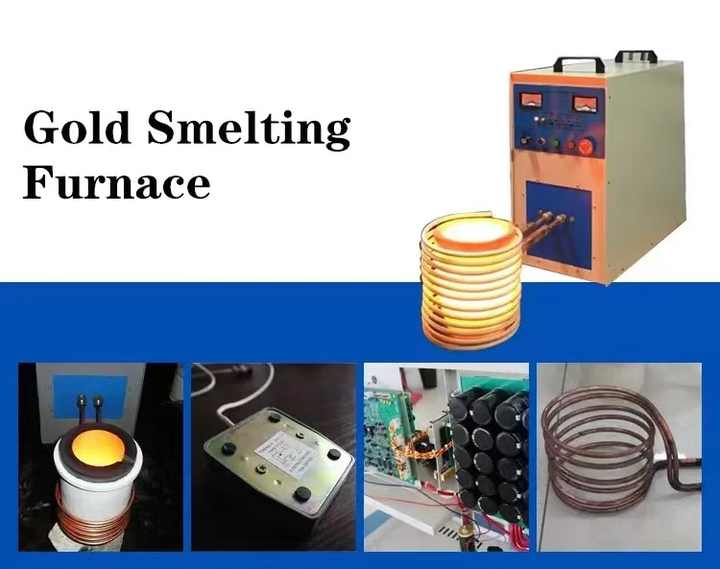

2. Smelting the Concentrated Ore

Once the ore is concentrated, it is ready for the smelting process. In precious metal smelting, the concentrated ore is placed in a furnace and heated to high temperatures, typically between 1,200 and 1,600 degrees Celsius. A chemical reducing agent, such as carbon or a flux material, is added to the furnace to help separate the precious metal from the other elements in the ore. As the ore melts, the precious metal separates and sinks to the bottom, while impurities rise to the surface, forming a layer of slag that can be removed.

3. Refining the Precious Metal

After smelting, the metal is typically not pure and may contain some residual impurities. To achieve the desired purity level, the metal undergoes a refining process. Various refining techniques can be used depending on the specific metal and the required purity. For example, the Wohlwill process is often used for gold, while the electrolytic refining method is common for silver and platinum. Refining is a crucial step in producing high-purity precious metals for industrial and commercial use.

Importance of Precious Metal Smelting

Precious metal smelting is essential for several reasons. Firstly, it allows for the extraction of valuable metals from their ores, making it possible to obtain usable metals that can be further refined or used in various applications. Without smelting, the precious metals contained in ore would remain locked within the rock and be of little value.

Secondly, smelting is vital for ensuring the purity of the final product. By separating precious metals from impurities and other non-metallic elements, smelting helps produce metals that meet industry standards for quality and performance. This is particularly important for applications where the purity of the metal is critical, such as in jewelry making, electronics, and investment products.

Applications of Precious Metal Smelting

Precious metal smelting plays a crucial role in several industries, where the quality and purity of the metal are of utmost importance. Below are some of the key applications of precious metal smelting.

1. Jewelry Making

The jewelry industry relies heavily on precious metal smelting to produce high-purity metals that can be alloyed with other elements to create different types of jewelry. The ability to smelt metals into various forms and purities allows jewelers to create a wide range of products, from simple silver rings to intricate gold necklaces and platinum earrings. Smelting ensures that the metals used in jewelry are of the highest quality, enhancing the durability, appearance, and value of the final product.

2. Electronics and Technology

In the electronics industry, precious metals like gold, silver, and platinum are used in various components due to their excellent conductivity, resistance to corrosion, and ability to form strong, stable connections. Precious metal smelting ensures that the metals used in electronic devices are of the highest quality, contributing to the performance and longevity of products such as smartphones, computers, and medical devices.

3. Investment and Bullion

Precious metal smelting is also essential in the production of bullion, which is used for investment purposes. Investors prefer bullion with high purity levels, as it is more valuable and can be traded or stored with confidence. Smelting is the process that makes this possible, producing gold bars, silver coins, and platinum ingots that meet strict industry standards for purity and quality.

Environmental Considerations in Precious Metal Smelting

While precious metal smelting is necessary for extracting and refining valuable metals, it is important to consider its environmental impact. The smelting process requires a significant amount of energy and can produce harmful emissions, including greenhouse gases and toxic substances. Additionally, the chemicals used in smelting, such as cyanide and mercury, can pose environmental and health risks if not properly managed.

To address these concerns, the industry is increasingly focusing on developing more sustainable smelting practices. This includes using cleaner energy sources, improving waste management practices, and developing alternative smelting technologies that minimize the use of hazardous chemicals.

Precious metal smelting is a critical process in the production of high-quality metals used in various industries. From jewelry making to electronics and investment, the importance of smelting cannot be overstated. By understanding the smelting process and its applications, industry professionals can ensure that they are producing metals that meet the highest standards for purity, performance, and sustainability.

As the demand for precious metals continues to grow, the need for efficient, sustainable, and environmentally friendly smelting practices will also increase. Through continued innovation and improvement in smelting techniques, the industry can meet the needs of the market while minimizing its impact on the environment.