process of purification of gold

The Process of Purification of Gold From Ore to Lustrous Metal

Gold, a symbol of wealth and prestige, has fascinated humans for thousands of years. Its lustrous appearance and malleability make it highly prized, not just for ornamental use but also for industrial applications. However, the journey from raw gold ore to the purest form of gold involves a series of intricate purification processes. This article delves into the various steps that constitute the process of purification of gold, revealing the science and art behind transforming crude ore into a refined metal.

Extraction and Initial Processing

The process begins with the extraction of gold-bearing ore from the earth. Typically, gold is found in veins within rocks, often mixed with other minerals like quartz. Once mined, the ore undergoes crushing and grinding to break it down into smaller particles, increasing the surface area and facilitating the liberation of gold from the surrounding rock.

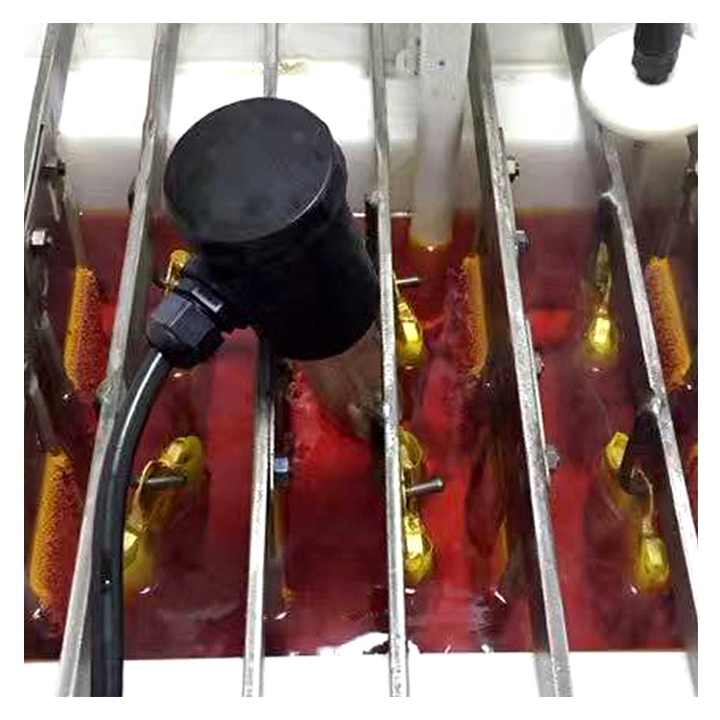

After crushing, the ore is subjected to a concentration process, which aims to separate the valuable gold particles from the waste material or gangue. This is often achieved through methods such as flotation, where the ore is mixed with water and reagents that cause the gold to attach to air bubbles, rising to the surface and forming a concentrate.

Leaching and Dissolution

The concentrated gold is then leached using chemicals to dissolve the gold particles. One common method is cyanidation, where the concentrate is treated with a cyanide solution, typically sodium cyanide, which forms a soluble complex with gold, allowing it to be separated from the rest of the material. This process is highly effective but requires careful handling due to the toxicity of cyanide.

Another method, especially useful for refractory ores that resist cyanidation, involves the use of pressure oxidation followed by cyanidation. In this process, the ore is exposed to high pressure and temperature in the presence of oxygen, breaking down the resistant compounds and making the gold more accessible to cyanide leaching.

Precipitation and Recovery

Once the gold is dissolved, it is precipitated out of the solution using a reducing agent. Zinc dust is commonly used for this purpose, reacting with the gold-cyanide complex and displacing the gold, which then settles out of the solution. This process is known as the Merrill-Crowe process and is widely used in gold extraction plants.

An alternative method involves electrowinning, where the gold is deposited onto a cathode through an electrolytic process. This method is favored for its ability to recover gold with a higher degree of purity and for its environmental benefits over chemical precipitation.

Final Refining and Purification

The precipitated gold is not yet in its purest form and typically contains trace amounts of other metals such as silver, copper, and lead. Further refining is necessary to achieve the desired purity level, which is often 99.99% or higher for commercial purposes.

Electrolytic refining is a popular method for achieving ultra-high purity. In this process, the impure gold is used as an anode in an electrolyte solution containing gold salts. Pure gold is deposited onto a cathode, leaving impurities behind in the electrolyte or as sludge at the bottom of the cell.

Another method used for purifying gold is the Parkes process, which involves adding zinc to a molten mixture of gold and silver. The zinc reacts with the base metals, forming an alloy that floats to the top of the molten mixture, allowing it to be removed, leaving behind nearly pure gold.

Sustainability and the Future of Gold Purification

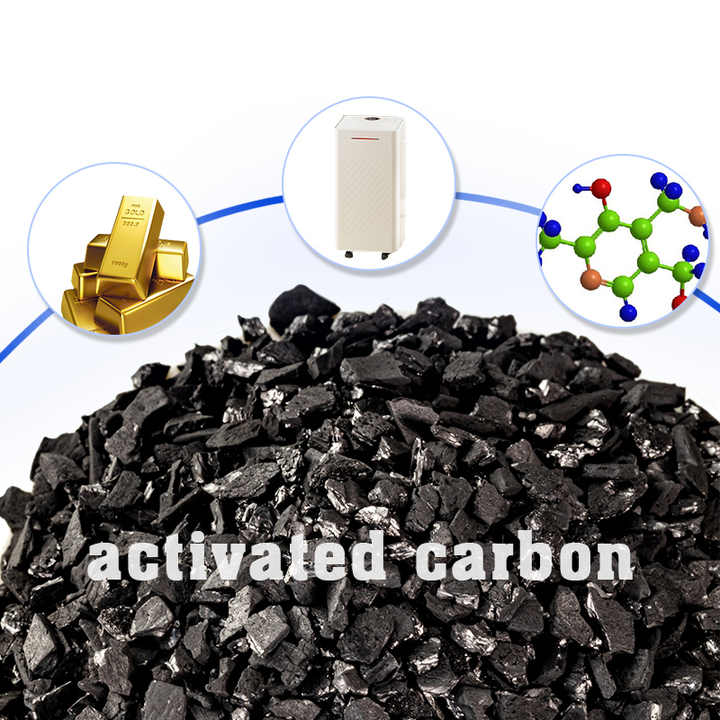

As awareness grows regarding the environmental impact of gold mining and processing, there is a concerted effort to develop more sustainable purification techniques. Innovations include the use of bioleaching, where bacteria are used to leach gold from ores, offering a potentially less toxic alternative to cyanide leaching.

Furthermore, advances in recycling and the recovery of gold from electronic waste present opportunities to reduce the reliance on new mining activities, thereby minimizing environmental damage and conserving natural resources.

The process of purification of gold is a complex and multi-faceted endeavor that combines traditional techniques with modern advancements. Each step in the process is crucial for ensuring that the final product meets the high standards of purity required for both aesthetic and industrial applications.