Process Of Refining Gold Filled Scrap

The Process of Refining Gold Filled Scrap: A Comprehensive Guide

Gold filled scrap represents a valuable resource for recovery and recycling. Whether it’s old jewelry, watch parts, or other items, these materials contain precious metals that can be refined and reused. This article will guide you through theprocess of refining gold filled scrap, highlighting key steps and techniques used by professionals to extract pure gold.

The Initial Sorting Process of Refining Gold Filled Scrap

Before any refining begins, the first step involves sorting the scrap into categories based on their composition and quality. This ensures that different types of materials are processed appropriately. For instance, gold-filled items are distinguished from solid gold pieces because they contain a layer of gold bonded to a base metal, typically brass or copper. Proper sorting helps in determining the rightprocess of refining gold filled scrapfor maximum efficiency.

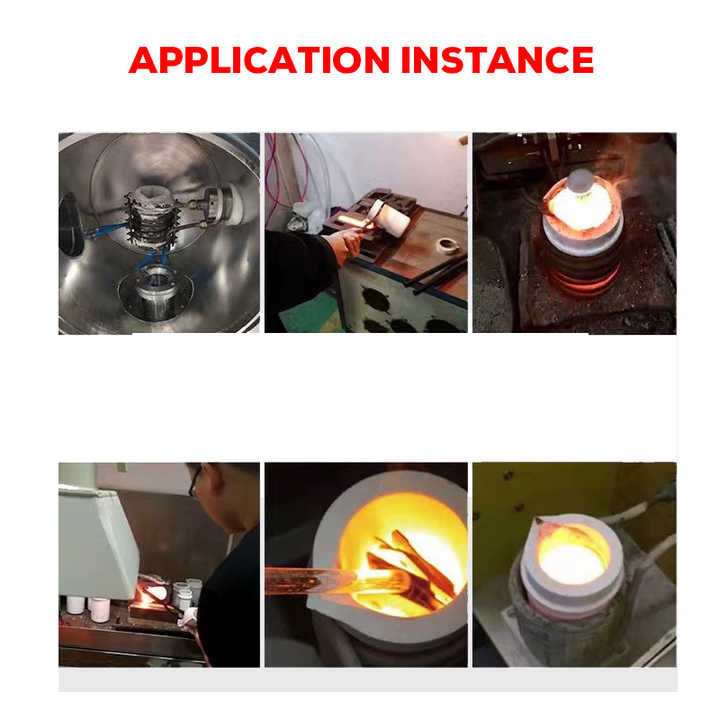

Crushing and Pulverizing in the Process of Refining Gold Filled Scrap

Once sorted, the next phase is crushing and pulverizing the material. This process breaks down larger pieces into smaller fragments, increasing surface area exposure for subsequent treatments. Specialized machinery from FRT Machinery designed for this task ensures that the gold-filled scrap is reduced to a manageable size without losing any of the precious metal content. Crushing is a critical part of theprocess of refining gold filled scrap, as it prepares the material for further refinement steps.

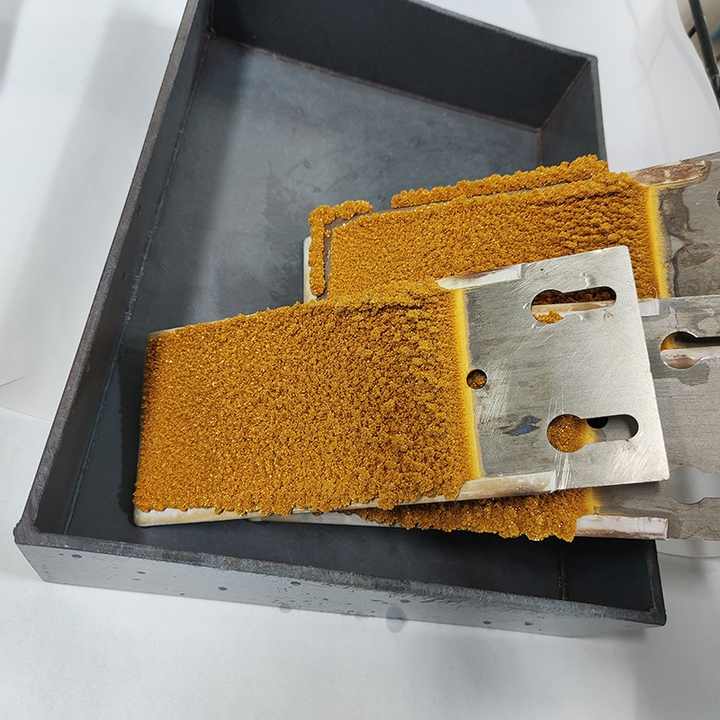

Chemical Leaching Techniques in the Process of Refining Gold Filled Scrap

After crushing, chemical leaching becomes essential in theprocess of refining gold filled scrap. This technique uses chemicals such as cyanide solutions to dissolve the gold from the base metals. The solution is carefully monitored to ensure safety and effectiveness. Leaching allows for the separation of gold from the surrounding materials, concentrating it for easier extraction.

Electrolysis During the Process of Refining Gold Filled Scrap

Following leaching, electrolysis is often employed in theprocess of refining gold filled scrap. This process involves passing an electric current through a conductive solution containing dissolved gold. As the current flows, metallic gold deposits onto a cathode, leaving impurities behind. Electrolysis is particularly useful for achieving higher purity levels in the refined gold, making it ready for various applications.

Final Purification Steps in the Process of Refining Gold Filled Scrap

The final stages of refining involve further purification techniques aimed at achieving the highest possible purity level of the recovered gold. Methods like precipitation, where impurities are removed by adding reagents that cause them to settle out, and distillation, which separates gold from other elements based on boiling points, are commonly used. These steps conclude theprocess of refining gold filled scrap, ensuring that the end product meets industry standards for quality and purity.

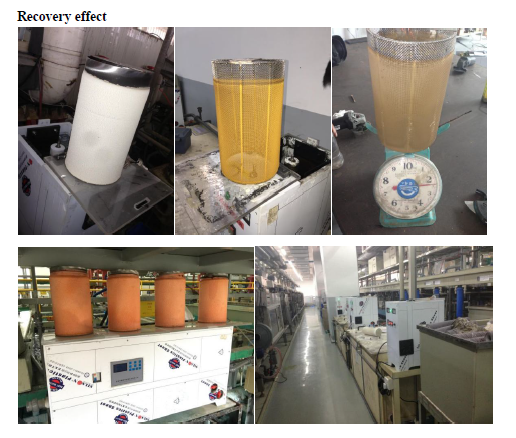

Sustainability and Environmental Considerations in the Process of Refining Gold Filled Scrap

It’s important to consider environmental impacts when discussing theprocess of refining gold filled scrap. Modern refining techniques, including those offered by FRT Machinery, focus on minimizing waste and reducing harmful emissions. By using closed-loop systems and recycling water and chemicals, refineries can significantly decrease their ecological footprint while still maintaining high efficiency in gold recovery processes.

By understanding these detailed steps involved in refining gold-filled scrap, one can appreciate the complexity and precision required to transform seemingly worthless materials into valuable resources. FRT Machinery’s commitment to innovation ensures that these processes remain both effective and environmentally friendly, contributing positively to the global effort towards sustainable resource management.