Process Of Refining Gold Ore

The Intricate Process of Refining Gold Ore

Gold ore refining is a meticulous process that transforms raw gold ore into pure gold, a precious metal renowned for its luster and durability. This transformation involves several stages, from crushing and grinding to purification, all requiring specialized machinery and techniques. FRT Machinery, a leading manufacturer in the field, offers insights into the key steps involved in refining gold ore.

Crushing and Grinding: Initial Stages of Gold Ore Refinement

The journey begins with the extraction of gold ore from mines, followed by the primary stage of processing—crushing and grinding. This step aims to reduce the size of the ore particles, making it easier to extract gold. FRT Machinery’s robust crushers and grinders are designed to handle the toughest materials efficiently, ensuring a consistent particle size that enhances the subsequent refining processes.

Leaching: Extracting Gold from Crushed Ore

Once the ore has been crushed and ground into a fine powder, leaching is employed to extract gold. In this process, cyanide solutions are used to dissolve gold particles, separating them from other minerals. FRT Machinery provides advanced leaching tanks equipped with agitators that ensure uniform mixing, maximizing the efficiency of gold dissolution. Proper pH control and aeration are critical during leaching, enhancing the rate of gold recovery.

Separation Techniques: Concentrating Gold from Leached Solution

After leaching, the solution containing dissolved gold must be separated from the remaining solids. This is achieved through various separation techniques such as carbon adsorption or resin ion exchange. FRT Machinery’s specialized separation units effectively concentrate gold, reducing the volume of solution for further processing. These systems are designed to minimize environmental impact by recycling chemicals and reducing waste.

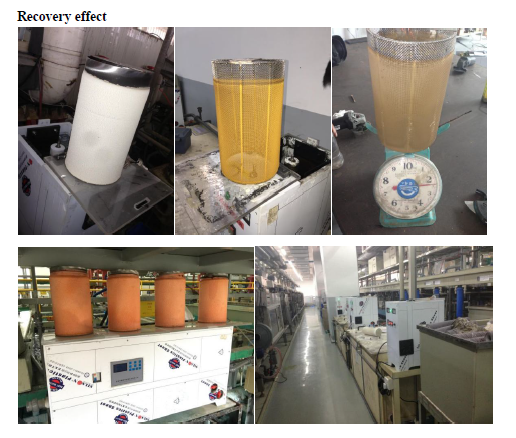

Electrowinning: Recovering Gold from Solution

Electrowinning is a crucial step where gold is recovered from the leached solution using an electric current. This process deposits gold onto cathodes within an electrolytic cell, creating a solid form of gold that can be further refined. FRT Machinery’s electrowinning cells are optimized for high recovery rates, ensuring that even trace amounts of gold are captured. Regular maintenance and monitoring of these cells are essential for maintaining optimal performance.

Smelting: Final Purification of Gold

The final step in refining gold ore is smelting, which involves heating the recovered gold to a high temperature to remove impurities. This process requires furnaces capable of reaching temperatures exceeding 1,000°C. FRT Machinery’s high-temperature furnaces are designed for efficient melting and purifying, producing gold of exceptional purity. Post-smelting, the gold is cast into ingots or bars, ready for market.

Environmental Considerations in Gold Ore Refining

While the focus on refining gold ore often centers around efficiency and yield, it is equally important to consider the environmental impact of these processes. FRT Machinery is committed to developing technologies that reduce water usage, chemical consumption, and waste production. By implementing sustainable practices throughout the refining cycle, manufacturers can contribute positively to both economic growth and environmental conservation.

Through each phase of refining gold ore, from initial crushing to final smelting, FRT Machinery supports the industry with innovative solutions designed to enhance productivity while minimizing environmental footprint. Understanding and optimizing these processes is key to ensuring the continued success of gold mining operations worldwide.