Details

- Home

- purification of gold process

purification of gold process

Table of Contents

ToggleThe Purification of Gold Process Methods and Techniques

Gold, one of the most precious and sought-after metals in the world, has been purified through various methods for thousands of years. The purification of gold process ensures that gold reaches the highest possible purity levels, making it suitable for use in industries such as jewelry, electronics, and finance. Understanding the different techniques used in gold purification helps highlight the intricate nature of refining this valuable resource. In this article, we explore the primary methods of purifying gold and the critical role each plays in ensuring the production of pure gold.

Importance of Gold Purification

Gold in its natural state, often found in ores or mixed with other metals and minerals, is rarely pure. Impurities such as silver, copper, and other trace elements can compromise the quality of gold. To obtain the desired level of purity for specific applications, these impurities must be removed through various refining processes.

The purification of gold process is essential for maintaining its value, especially for use in fine jewelry, where the aesthetic and quality must be flawless. In industries like electronics, where gold is used for its excellent conductivity and resistance to corrosion, even small impurities can affect performance. Thus, achieving high-purity gold is critical for both functionality and value.

Common Methods of Gold Purification

Fire Assaying

Fire assaying is one of the oldest and most reliable methods for the purification of gold process. This method has been used for centuries and remains widely popular today due to its effectiveness.

- Process: Gold is heated in a furnace at extremely high temperatures to separate it from other metals and impurities. A lead-based flux is often used to combine with base metals, allowing the pure gold to settle at the bottom of the crucible.

- Advantages: Fire assaying provides accurate results and can be used to purify both small and large amounts of gold. It is especially useful for separating gold from silver and other alloyed metals.

Aqua Regia

Aqua regia is a chemical method for purifying gold that uses a mixture of nitric acid and hydrochloric acid. This method is particularly effective for separating gold from other metals.

- Process: Gold is dissolved in the acid mixture, forming a solution. Impurities either do not dissolve or can be filtered out. The pure gold is then precipitated from the solution using chemical agents, typically by adding a reducing agent like sodium metabisulfite.

- Advantages: Aqua regia is highly effective at purifying gold from ores or scrap metals. It is widely used in laboratories and small-scale operations because it can achieve very high purity levels.

Electrolytic Refining

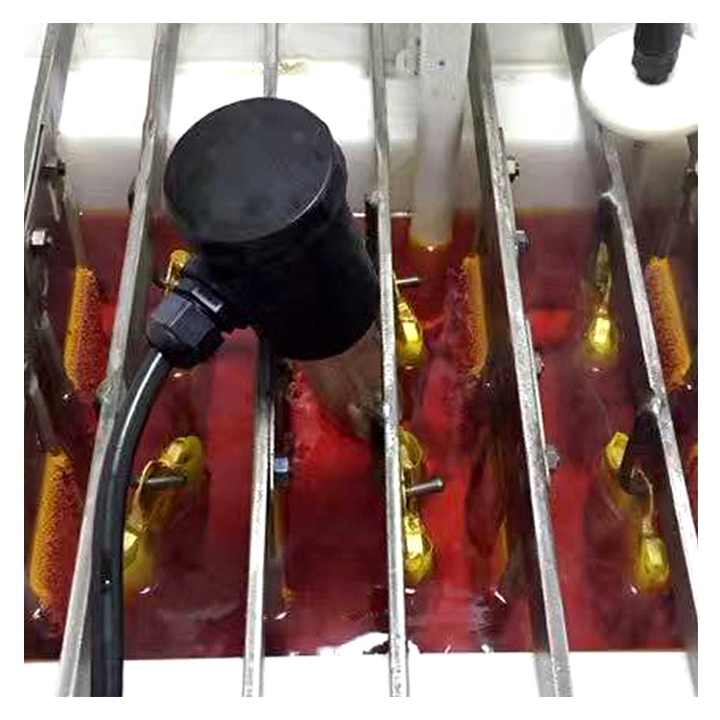

Electrolytic refining is a modern method that uses electricity to purify gold. This process is particularly useful for refining large amounts of gold and achieving very high levels of purity.

- Process: In electrolytic refining, gold is placed in an electrolyte solution, and an electrical current is passed through it. The gold dissolves into the solution, and pure gold is deposited onto a cathode. The impurities, meanwhile, either remain in the solution or settle as sludge.

- Advantages: Electrolytic refining is highly efficient and can yield gold with a purity level of 99.99%. It is a preferred method in large-scale industrial operations due to its accuracy and scalability.

Miller Process

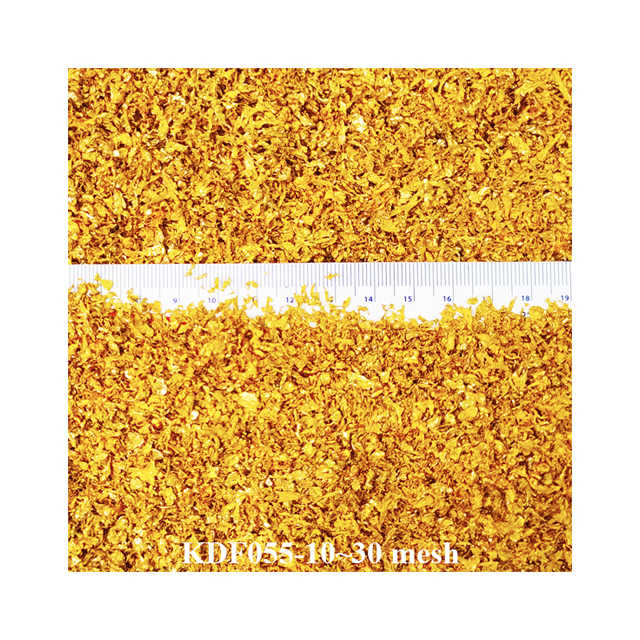

The Miller process is a widely used refining method that produces gold with a purity of 99.5%. This method is typically used by gold refineries as the first step in a multi-stage purification process.

- Process: Chlorine gas is bubbled through molten gold, causing the impurities to form chlorides, which rise to the surface and can be skimmed off. This leaves behind relatively pure gold.

- Advantages: The Miller process is fast and efficient, making it ideal for processing large amounts of gold. However, it is usually followed by other methods, such as the Wohlwill process, to achieve even higher levels of purity.

Wohlwill Process

The Wohlwill process is an extension of electrolytic refining, specifically designed to achieve the highest possible purity levels in gold.

- Process: Similar to electrolytic refining, gold is dissolved into an electrolyte solution, but the Wohlwill process uses an electrolyte of gold chloride. Pure gold is deposited onto the cathode, while impurities remain in the solution.

- Advantages: The Wohlwill process can produce gold with a purity level of 99.999%. It is commonly used in large refineries to produce gold of the highest quality for investment or industrial purposes.

Challenges in the Purification of Gold

While the purification of gold process is essential for obtaining pure gold, several challenges exist in this intricate procedure:

- Cost: Some gold purification methods, such as the Wohlwill process, are expensive and require significant energy and resources, making them more suitable for large-scale operations.

- Environmental Impact: Methods like aqua regia use hazardous chemicals, which must be disposed of properly to prevent environmental damage.

- Yield Losses: During purification, a small percentage of gold may be lost, particularly in processes like fire assaying or chemical refining. Minimizing these losses is crucial to ensure economic efficiency.

The purification of gold process involves several key methods, each designed to remove impurities and produce gold of varying purity levels. From traditional techniques like fire assaying to modern methods such as electrolytic refining, gold can be purified for a range of applications. Each method offers distinct advantages and is chosen based on factors like the amount of gold being processed, the desired purity level, and the specific application of the refined gold.

As the demand for pure gold continues to grow, especially in high-tech industries and investment markets, refining techniques will continue to evolve, providing more efficient, cost-effective, and environmentally friendly solutions for purifying gold.