Red Slag By Product Of Refining Gold

Understanding Red Slag: A By-Product of Refining Gold

Gold refining is a complex process that involves several stages to purify raw gold into its purest form. One of the by-products generated during this process is red slag. This material, while often overlooked, can provide valuable insights into the efficiency of the refining process and even has potential secondary uses. FRT Machinery, a leading manufacturer of refining equipment, explores the nature of red slag and its implications for the industry.

Characteristics of Red Slag in Gold Refining

Red slag is a by-product formed when impurities are separated from gold during the refining process. These impurities, including oxides and other metallic compounds, combine with fluxes added to the molten mixture, resulting in a bright red residue. The color comes from iron oxide, which is a common component of the slag. Understanding the composition and properties of red slag is crucial for optimizing the refining process and managing waste effectively.

The Formation Process of Red Slag During Gold Refining

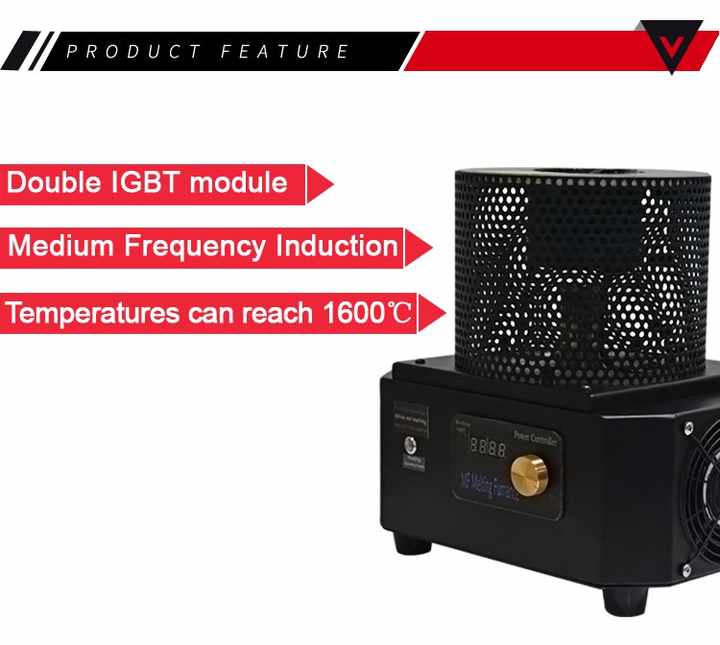

During the smelting stage of gold refining, the raw material is heated to extremely high temperatures, causing it to melt. At these temperatures, unwanted elements within the gold alloy rise to the surface, forming a layer of slag. The formation of red slag is indicative of a successful separation process, where the majority of impurities have been removed. FRT Machinery’s advanced refining systems ensure that this separation is efficient, minimizing the amount of gold lost in the slag.

Environmental Impact and Management of Red Slag

The disposal of red slag must be managed carefully due to its potentially hazardous components. Proper handling and storage prevent environmental contamination and ensure compliance with regulations. Some refineries are exploring ways to recycle red slag or use it in construction materials, reducing waste and promoting sustainability. FRT Machinery supports these initiatives by developing technologies that facilitate the safe and effective processing of red slag.

Utilizing Red Slag: Opportunities and Challenges

Despite being a waste product, red slag contains valuable metals such as copper, lead, and zinc, which can be recovered through further processing. However, the cost-effectiveness of extracting these metals depends on the slag’s composition and market prices. FRT Machinery is committed to researching innovative methods for recovering metals from red slag, aiming to turn what was once considered waste into a resource.

Innovations in Reducing Red Slag Production

Continuous efforts are being made to reduce the production of red slag during gold refining. By improving the efficiency of refining processes, not only is the yield of pure gold increased, but the volume of slag produced is also minimized. FRT Machinery leads the way in developing more precise control systems and cleaner refining technologies, contributing to a more sustainable future for the gold industry.

Conclusion: The Role of Red Slag in Modern Gold Refining

While red slag has traditionally been viewed as a waste product, it plays a critical role in understanding and improving gold refining processes. Its analysis can reveal inefficiencies in the refining cycle, guiding refineries towards more sustainable practices. As FRT Machinery continues to innovate, the industry moves closer to realizing the full potential of red slag, transforming it from a by-product into a valuable asset.