Refining Gold Computer Parts

Refining Gold from Computer Parts: A Comprehensive Guide

In today’s digital age, the demand for precious metals like gold has skyrocketed, particularly within the electronic waste (e-waste) recycling sector. With millions of outdated computers being discarded annually, the potential for recovering valuable materials such as gold from these devices is enormous. FRT Machinery, a leader in the field of e-waste recycling solutions, offers advanced techniques and equipment designed specifically for refining gold computer parts. This article delves into the process of extracting and purifying gold from computer components, highlighting key steps and best practices.

Benefits of Refining Gold Computer Parts

Refining gold from computer parts not only helps in reducing environmental pollution but also provides a sustainable source of this precious metal. By recycling gold from old electronics, companies can significantly reduce their reliance on mining, which often involves environmentally harmful practices. Moreover, the economic benefits are substantial, as the value of gold recovered can offset the costs associated with processing e-waste.

Preparation for Refining Gold Computer Parts

Before the actual refining process begins, it is crucial to prepare the computer parts properly. This includes dismantling the devices and sorting out components that contain gold, such as motherboards, processors, and RAM sticks. Using specialized tools and machinery provided by FRT Machinery, technicians can efficiently separate these parts, ensuring a high yield of gold-containing materials ready for further processing.

Chemical Processes in Refining Gold Computer Parts

Once the gold-containing components are isolated, chemical processes come into play to extract the gold. One common method is leaching, where a solution of cyanide is used to dissolve the gold from the circuit boards. After leaching, the gold is precipitated out using zinc dust. Another technique involves smelting, which melts down the components at high temperatures to separate the gold from other metals and impurities. Both methods require precise control over conditions to maximize recovery rates while minimizing environmental impact.

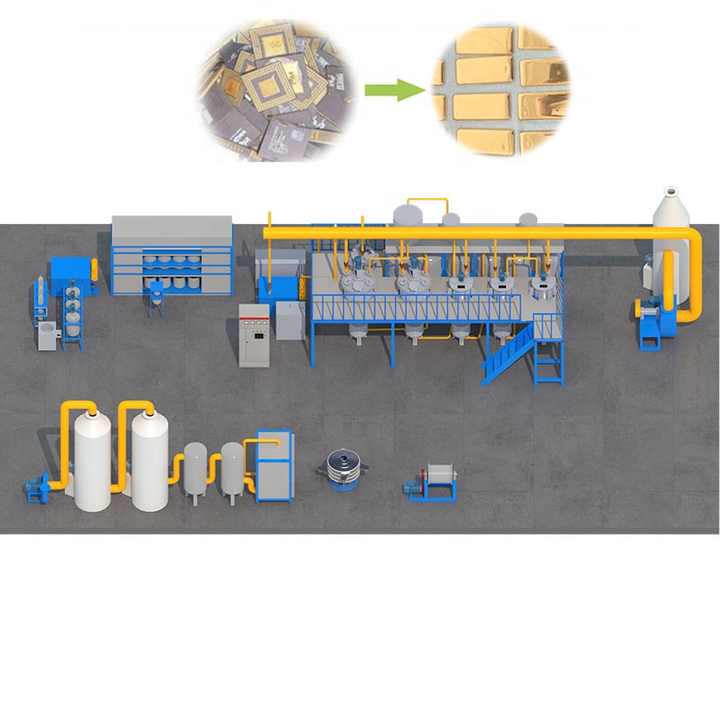

Equipment for Refining Gold Computer Parts

FRT Machinery offers a range of equipment tailored for refining gold from computer parts. Their machines are designed to handle every step of the process, from initial shredding and sorting to the final purification stages. Key pieces of equipment include shredders for breaking down larger components, magnetic separators for removing ferrous materials, and specialized leaching tanks that ensure efficient gold extraction under controlled conditions.

Safety Considerations When Refining Gold Computer Parts

Safety must be a top priority when dealing with chemicals and high-temperature processes involved in gold refining. Proper protective gear, ventilation systems, and safety protocols are essential to protect workers from potential hazards. FRT Machinery ensures that all their equipment meets stringent safety standards, providing comprehensive training programs to help operators understand and implement best practices for safe operation.

Environmental Impact of Refining Gold Computer Parts

While refining gold from computer parts is generally considered more eco-friendly than traditional mining, it still poses certain environmental challenges. The use of chemicals like cyanide requires careful management to prevent contamination of water sources and soil. FRT Machinery addresses these concerns by incorporating advanced filtration systems and waste management strategies into their equipment design, promoting responsible recycling practices throughout the industry.

Future Trends in Refining Gold Computer Parts

As technology advances, so too does the efficiency and sustainability of gold refining processes. FRT Machinery continues to innovate, developing new methods and technologies aimed at increasing recovery rates while further reducing environmental impacts. By staying at the forefront of these developments, they help ensure that the practice of refining gold from computer parts remains a viable and responsible option for years to come.