Refining Gold Computer Pins

Refining Gold from Computer Pins: A Precise Art

The Importance of Gold in Computer Pins

Gold has been a staple material in the electronics industry due to its excellent conductivity and resistance to corrosion. In particular, computer pins often contain gold plating to ensure reliable connections and long-lasting performance. As technology advances and electronic devices become more compact, the demand for gold in these components continues to grow. However, this also means that when these devices reach their end-of-life, there’s a significant amount of gold that can be recovered and recycled.

Understanding the Process of Refining Gold Computer Pins

The process of refining gold from computer pins involves several steps designed to extract the precious metal while removing impurities. FRT Machinery offers specialized equipment tailored for this task, ensuring efficiency and environmental responsibility. Let’s delve into the key stages of refining gold from computer pins.

Preparing Computer Pins for Refining

Before the actual refining process begins, it’s crucial to prepare the computer pins properly. This includes sorting them based on their composition and cleaning them to remove any contaminants. Using FRT Machinery’s automated systems, this preparation phase can be streamlined, reducing labor costs and improving overall throughput.

Utilizing Electrolysis for Gold Extraction

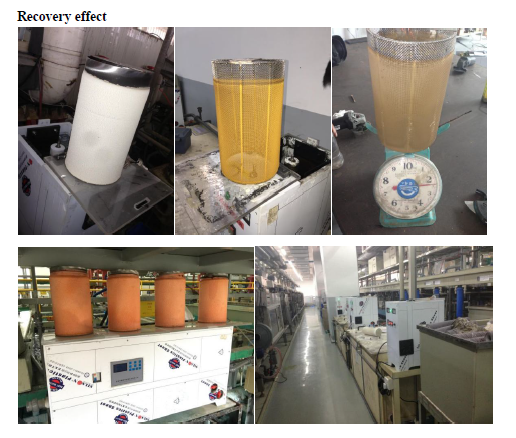

One of the most effective methods for extracting gold from computer pins is through electrolysis. This technique involves passing an electric current through a solution containing the pins, causing the gold to separate from other materials. FRT Machinery’s advanced electrolysis units are designed to maximize gold recovery rates while minimizing energy consumption.

Implementing Chemical Leaching for Enhanced Recovery

Chemical leaching is another method used in the refining process, especially when dealing with smaller quantities of gold or when higher purity levels are required. By using specific chemicals, such as cyanide solutions, gold can be dissolved and then precipitated out, leaving behind non-valuable metals. FRT Machinery ensures that all chemical processes are carried out safely and comply with environmental regulations.

Final Purification and Testing

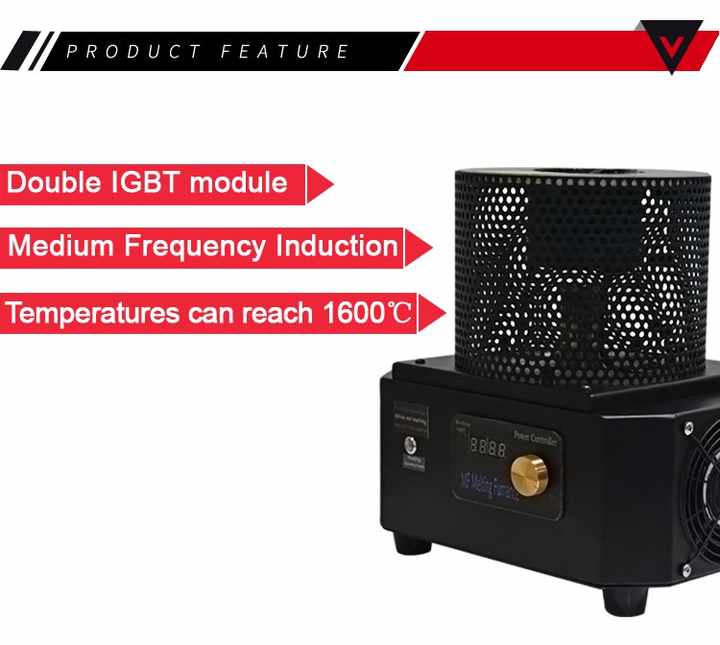

After the initial extraction, the gold must undergo further purification to achieve the desired level of purity. This step often involves techniques like smelting and refining in specialized furnaces provided by FRT Machinery. Once purified, the gold is tested for quality assurance, ensuring it meets market standards for resale or reuse in new products.

The Role of FRT Machinery in Sustainable Gold Refining

FRT Machinery is committed to advancing sustainable practices in the gold refining industry. By providing state-of-the-art equipment and solutions, they help businesses not only recover valuable resources but also reduce their environmental footprint. Whether you’re a small-scale operation or a large industrial facility, FRT Machinery has the tools and expertise to support your recycling needs efficiently and responsibly.

Through continuous innovation and dedication to sustainability, FRT Machinery plays a pivotal role in making the process of refining gold from computer pins not just economically viable but environmentally conscious as well.