refining gold filled scrap

Refining Gold Filled Scrap A Step-by-Step Guide

Refining gold filled scrap is a practical way to recover valuable gold content from materials that are coated or filled with gold. This process differs from refining solid gold items, as the gold layer is typically bonded to a base metal, such as brass or copper. In this article, we will explore the process of refining gold filled scrap, the methods used, and the reasons why this process is essential for recovering gold.

What Is Gold Filled Scrap?

Gold filled scrap refers to items that are not solid gold but have a thick layer of gold bonded to a base metal. The gold content in gold filled items is usually higher than in gold-plated items, typically making up around 5% or more of the item’s total weight. These items may include jewelry, watches, and other decorative objects. Unlike gold plating, which involves a very thin layer of gold, gold filled items contain a significant amount of gold that can be worth recovering through the refining process.

Why Refining Gold Filled Scrap Is Important

Refining gold filled scrap is important for several reasons:

- Maximizing Value: Recovering gold from scrap ensures that the valuable gold content does not go to waste.

- Environmental Sustainability: Refining gold filled scrap helps recycle materials, reducing the need for gold mining and its associated environmental impacts.

- Profitability: For businesses and individuals dealing with gold, refining scrap is a cost-effective way to recover and resell gold.

Methods for Refining Gold Filled Scrap

Several methods are available for refining gold filled scrap, with each offering a different approach based on the desired purity and scale of operation. Here are the most common methods:

Chemical Refining

Chemical refining is one of the most effective methods for extracting gold from gold filled scrap. It involves dissolving the base metals and leaving behind the pure gold.

- Aqua Regia Process: Aqua regia is a mixture of nitric acid and hydrochloric acid, which dissolves gold and other metals. This process begins by placing the gold filled scrap in a solution of aqua regia, which dissolves both the base metals and gold. Once the base metals are dissolved, the gold can be precipitated out using a reducing agent like sodium metabisulfite.

- Electrolytic Refining: Another chemical method involves using an electrolytic cell to separate the gold from the base metal. The scrap is submerged in a solution where the gold is drawn to the cathode, leaving behind the base metals.

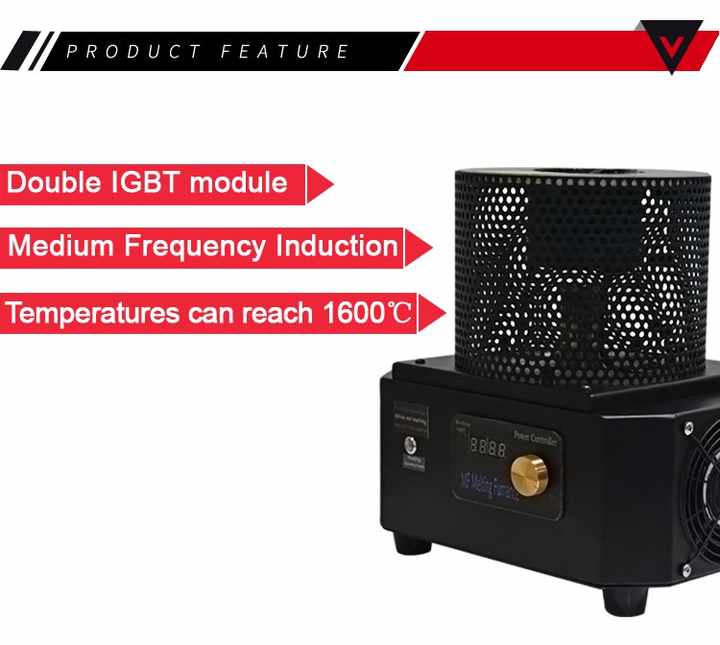

Fire Refining

Fire refining is a traditional method that involves melting the gold filled scrap in a furnace. This method is effective for larger quantities of scrap. During the process, the base metals will oxidize and separate from the molten gold. The remaining gold can be collected and further refined if necessary.

- Flux Use: A flux, such as borax or soda ash, is added to the melt to help separate impurities from the gold during the fire refining process. The flux acts as a cleansing agent, making it easier to collect the pure gold.

The Refining Process

Refining gold filled scrap follows these general steps:

- Collection of Gold Filled Scrap: Gather the scrap items that contain gold, such as broken jewelry, watches, and other items.

- Initial Cleaning: Clean the scrap to remove dirt and contaminants before refining.

- Choosing the Refining Method: Depending on the quantity of scrap and desired purity level, select either chemical or fire refining. For small-scale refiners, chemical methods such as the aqua regia process are often more accessible, while larger operations may prefer fire refining.

- Dissolving Base Metals: If using the aqua regia process, the scrap is placed in the acid solution to dissolve the base metals.

- Gold Precipitation: After the base metals dissolve, the gold is precipitated out of the solution using a chemical agent like sodium metabisulfite.

- Gold Collection and Melting: The recovered gold is collected and melted into bars or other forms for resale or reuse.

- Further Purification: Depending on the desired purity, the gold may undergo additional refining steps to reach a higher level of purity.

Safety Considerations

Refining gold filled scrap involves handling hazardous chemicals and high temperatures. It is crucial to follow these safety guidelines:

- Wear protective gloves, goggles, and a lab coat when working with chemicals.

- Ensure proper ventilation to avoid inhaling toxic fumes.

- Handle acids and other chemicals with care and follow disposal regulations.

Refining gold filled scrap is an effective way to recover valuable gold that might otherwise be lost. By using chemical methods like aqua regia or traditional fire refining, individuals and businesses can extract pure gold from scrap items. The process not only maximizes the value of gold-filled items but also contributes to sustainable practices by recycling precious materials. Whether you are a hobbyist or a professional refiner, refining gold filled scrap offers a rewarding way to recover gold.