Refining Gold Through Electrolysis

Refining Gold Through Electrolysis: A Comprehensive Guide

When it comes to refining gold, electrolysis stands out as one of the most effective methods for achieving purity levels that other techniques simply cannot match. This process, which involves passing an electric current through a solution containing gold, has been refined over the years to become a cornerstone of modern gold purification. FRT Machinery, a leader in manufacturing advanced electrolytic refining systems, offers insights into the intricacies and benefits of this technique.

Electrolytic Bath Preparation

The first step in the electrolytic refining process involves preparing the bath where the gold will be purified. Typically, this bath consists of a solution of hydrochloric acid and sodium chloride, creating an environment conducive to the dissolution of impurities while leaving the gold unaffected. FRT Machinery’s specialized tanks are designed to withstand the corrosive nature of these solutions, ensuring both safety and efficiency during the entire refining cycle.

Role of Cathodes and Anodes in Electrolysis

At the heart of the electrolysis process are the cathodes and anodes. The anode, made from impure gold, is placed opposite the cathode, usually composed of pure gold or another inert material. When an electric current is applied, impurities in the anode dissolve into the electrolyte while pure gold migrates towards the cathode. FRT Machinery’s innovative electrode designs maximize the surface area contact, enhancing the rate of gold migration and reducing refining times significantly.

Precision Control Over Current and Voltage

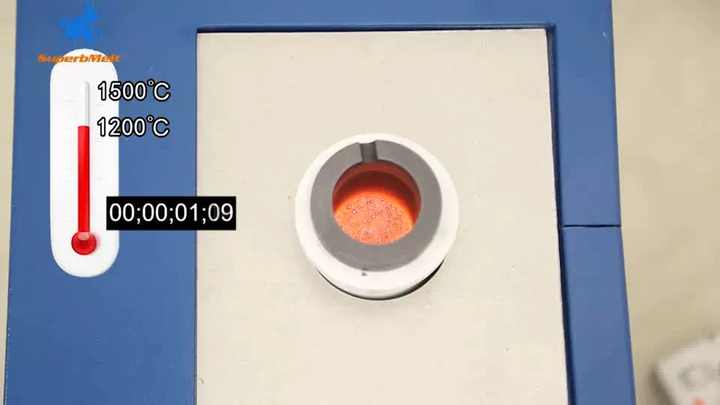

Achieving optimal results in electrolytic gold refining requires precise control over the electrical parameters. Too much current can lead to overheating and degradation of the electrodes, while too little may result in inefficient refining. FRT Machinery’s systems incorporate advanced digital controllers that monitor and adjust the current and voltage in real-time, ensuring consistent purity levels across all batches.

Importance of Solution Circulation

Maintaining a steady flow of electrolyte solution is crucial for the success of the electrolysis process. Proper circulation ensures that fresh solution constantly contacts the electrodes, promoting uniform refining and preventing the buildup of insoluble impurities. FRT Machinery equips its refining systems with efficient circulation mechanisms, guaranteeing that every part of the gold is exposed to the refining conditions equally.

Environmental Considerations and Safety Measures

While highly effective, electrolytic gold refining must be conducted with due consideration for environmental impact and operator safety. FRT Machinery adheres to stringent guidelines in the design and operation of its refining systems, incorporating features such as sealed tanks and automated handling processes that minimize exposure to hazardous materials and reduce the risk of leaks or spills.

Future Innovations in Electrolytic Refining

As technology advances, so does the potential for refining gold more efficiently and sustainably. FRT Machinery remains committed to researching and developing new methods that could further enhance the capabilities of electrolytic refining. From exploring alternative electrolyte solutions to improving the recyclability of used materials, the future looks bright for those seeking cleaner, more efficient ways to refine gold.

By understanding the principles behind electrolytic gold refining and utilizing state-of-the-art equipment like that offered by FRT Machinery, gold refiners can achieve unparalleled purity levels while maintaining operational efficiency and environmental responsibility.