refining of silver

The Refining of Silver Techniques, Benefits, and Modern Practices

The refining of silver is a critical process that transforms raw silver ore or scrap into a high-purity form suitable for various applications. This process is essential for industries that require silver for its functional and aesthetic properties, such as jewelry, electronics, and investments. This article explores the refining of silver, detailing the techniques used, the benefits of refining, and modern advancements in the field.

Understanding the Refining of Silver

The refining of silver involves separating pure silver from impurities found in raw ore or scrap material. This process enhances the quality of the silver, ensuring that it meets industry standards for purity and performance. The primary goal is to produce silver that is free from contaminants and suitable for specific applications, ranging from high-end jewelry to advanced electronic components.

Techniques in the Refining of Silver

Traditional Smelting

One of the oldest methods for the refining of silver is smelting. In this process, silver ore or scrap is heated to high temperatures in a furnace. The addition of fluxes, such as borax and soda ash, helps to separate impurities from the molten silver. The impurities form a slag that is removed, leaving behind a purer form of silver. This method is effective for achieving high levels of purity and is still widely used today.

Fire Assay

Fire assay is another traditional technique used in the refining of silver. This method involves heating a sample of silver with fluxes in a high-temperature furnace. The process separates silver from base metals and other impurities. The resulting silver is then tested to ensure its purity. Fire assay is renowned for its accuracy and reliability in determining the purity of silver.

Electrolytic Refining

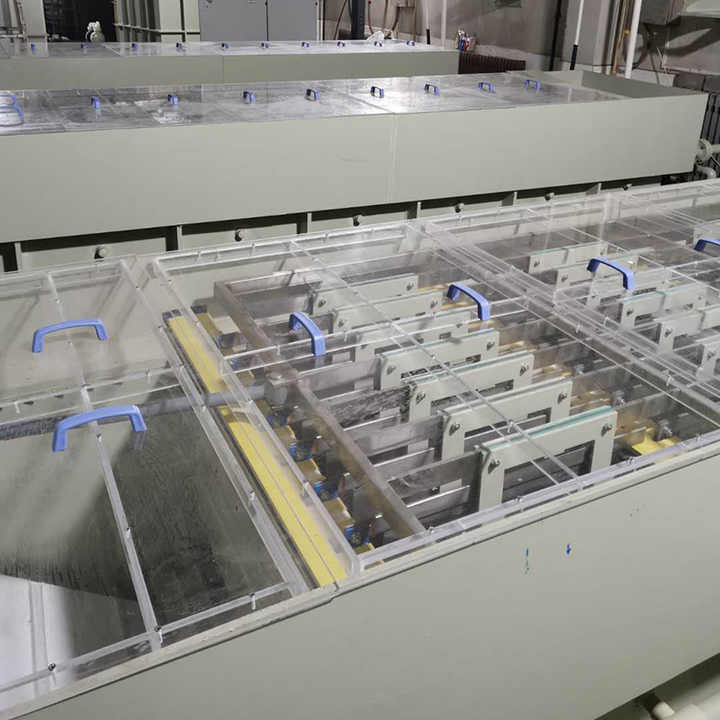

For achieving very high purity levels, electrolytic refining is often employed. In this method, silver is dissolved in an electrolyte solution and then deposited onto a cathode. This process uses electrolysis to remove any remaining impurities and ensures that the silver meets the highest purity standards. Electrolytic refining is particularly useful for refining scrap silver and recovering silver from electronic waste.

Chemical Refining

Chemical refining is another method used to purify silver. This involves using chemical reagents to dissolve impurities and separate them from the silver. The process typically includes the use of acids or other chemicals that react with the impurities, leaving behind pure silver. Chemical refining is often used in conjunction with other refining techniques to achieve the desired purity.

Benefits of Refining Silver

The refining of silver offers several key benefits:

- Increased Purity: Refining removes impurities and enhances the purity of silver, making it suitable for high-quality applications.

- Enhanced Value: Pure silver has a higher market value compared to unrefined silver, which is beneficial for both commercial and investment purposes.

- Resource Conservation: Refining allows for the recycling of silver from scrap materials, reducing the need for new mining operations and conserving natural resources.

- Improved Performance: High-purity silver is essential for applications that require excellent conductivity, durability, and aesthetic qualities.

Modern Practices in Silver Refining

The refining of silver has evolved with advancements in technology and practices. Modern refining facilities employ advanced equipment and techniques to improve efficiency, safety, and environmental sustainability. Key advancements include:

- Automated Systems: Automated refining systems enhance precision and consistency in the refining process. These systems can control temperature, timing, and chemical reactions with high accuracy.

- Environmental Controls: Modern refining facilities incorporate technologies to minimize environmental impact. This includes improved filtration systems, waste management practices, and the use of eco-friendly chemicals.

- Advanced Analytical Techniques: Techniques such as X-ray fluorescence (XRF) and inductively coupled plasma (ICP) spectroscopy are used to analyze the composition of silver with high precision, ensuring accurate assessment of purity.

The refining of silver is a crucial process that transforms raw or scrap silver into a high-purity metal suitable for a wide range of applications. Through various techniques such as smelting, fire assay, electrolytic refining, and chemical refining, silver can be purified to meet industry standards. The benefits of refining include increased purity, enhanced value, and resource conservation. With modern advancements in technology and practices, the refining of silver continues to evolve, offering more efficient and environmentally friendly solutions for producing high-quality silver.