silver cell refining

Understanding Silver Cell Refining A Key Process for Purifying Silver

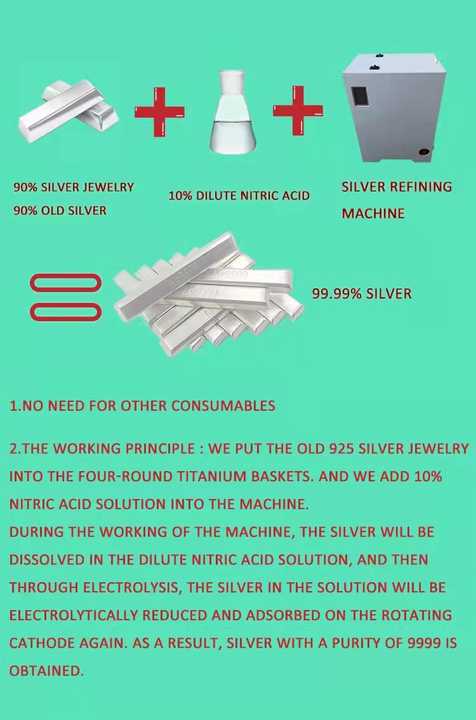

Silver cell refining is a highly efficient and widely used process for purifying silver to achieve the highest levels of purity. This electrochemical method is employed by refineries and industrial facilities to refine large quantities of silver, removing impurities and producing silver of remarkable quality. In this article, we will explore the silver cell refining process, its advantages, and how it compares to other silver refining methods.

What Is Silver Cell Refining?

Silver cell refining is an electrochemical refining process that relies on the principles of electrolysis to purify silver. In this method, silver is dissolved in an electrolyte solution and then deposited as pure silver onto a cathode. Impurities in the silver remain in the solution or form a residue that is easily separated from the refined silver. This process is particularly effective for producing silver with a purity of 99.99% or higher.

Silver cell refining is primarily used for refining large quantities of silver, such as in the production of bullion or industrial-grade silver. It is favored for its ability to produce exceptionally pure silver and its efficiency in handling high volumes of material.

How Does Silver Cell Refining Work?

The silver cell refining process relies on the principle of electrolysis, in which an electric current is passed through a silver-containing solution to purify the metal. Here’s a breakdown of the steps involved in silver cell refining:

- Preparation of the Anode: The first step in silver cell refining is to prepare the silver anode, which contains a mixture of silver and impurities. This can be scrap silver, low-grade silver, or silver from other refining processes that need further purification.

- Electrolyte Solution: The anode is submerged in an electrolyte solution, typically containing silver nitrate. The solution helps conduct electricity and facilitates the movement of silver ions from the anode to the cathode.

- Electrolysis: An electric current is passed through the electrolyte solution. This causes the silver from the anode to dissolve into the solution as silver ions. The silver ions then migrate to the cathode, where they are deposited as pure silver.

- Separation of Impurities: Impurities in the silver, such as copper, gold, or other metals, do not dissolve in the electrolyte solution. These impurities either remain in the anode or fall to the bottom of the cell as a residue known as anode slime. This anode slime can be further processed to recover valuable metals like gold or platinum.

- Collection of Refined Silver: As the electrolysis process continues, pure silver builds up on the cathode. Once the desired amount of silver has been refined, it is removed from the cell and processed into bars, ingots, or other forms of silver.

Advantages of Silver Cell Refining

Silver cell refining offers several advantages over traditional refining methods, making it the preferred choice for achieving high-purity silver. Some key benefits of silver cell refining include:

Exceptional Purity

One of the primary reasons for using silver cell refining is its ability to produce silver of exceptional purity. This method can achieve purity levels as high as 99.99%, which is critical for applications that require ultra-pure silver, such as in the electronics industry, jewelry making, and investment bullion production.

Efficient Recovery of Valuable Metals

During the silver cell refining process, impurities such as gold, platinum, and palladium are separated from the silver and collected in the anode slime. This makes it possible to recover these valuable metals for further processing or sale, enhancing the overall profitability of the refining operation.

High Throughput

Silver cell refining is an efficient method for processing large quantities of silver. Industrial refineries can handle significant volumes of material using this method, making it ideal for large-scale refining operations. The process is continuous, allowing for the constant production of high-purity silver.

Environmentally Friendly

Compared to traditional smelting methods, silver cell refining is considered more environmentally friendly. The process generates fewer harmful emissions, and the electrolyte solution can be reused, reducing waste. Additionally, the recovery of valuable metals from anode slime minimizes the environmental impact of mining and metal extraction.

Applications of Silver Cell Refining

Silver cell refining is used in various industries where high-purity silver is essential. Some common applications include:

- Jewelry Manufacturing: Jewelers require silver with a high degree of purity to create fine jewelry. Silver cell refining ensures that the silver used in jewelry production is free of impurities, resulting in high-quality products.

- Electronics: The electronics industry relies on ultra-pure silver for the production of electrical contacts, conductors, and other components. Silver cell refining produces the purity levels needed for these precise applications.

- Bullion Production: Investment-grade silver bullion, such as silver coins and bars, must meet strict purity standards. Silver cell refining ensures that the silver used in bullion meets these standards, making it suitable for investment purposes.

- Silverware: High-end silverware manufacturers use refined silver to produce luxurious tableware that is both functional and aesthetically pleasing.

Comparing Silver Cell Refining to Other Methods

While silver cell refining is highly effective for producing ultra-pure silver, it is not the only method available. Other methods, such as smelting and chemical refining, are also used depending on the scale and desired outcome of the refining process.

- Smelting: Smelting involves heating silver ore or scrap to high temperatures to separate silver from impurities. While smelting is effective for producing silver, it typically results in lower purity levels compared to silver cell refining. Smelting is also more energy-intensive and may not be suitable for achieving ultra-high purity.

- Chemical Refining: Chemical refining uses chemical reactions to purify silver. This method can achieve high levels of purity, but it may not be as efficient for large-scale operations as silver cell refining. Chemical refining also requires the handling of hazardous substances, which may pose environmental and safety concerns.

Silver cell refining is a crucial process for producing high-purity silver, offering significant advantages in terms of efficiency, purity, and environmental impact. Whether used for jewelry, electronics, or bullion production, the silver cell refining method ensures that the silver meets the highest quality standards. By understanding how this process works and its benefits, refiners can continue to produce valuable, ultra-pure silver for various industries.