silver refining

Silver Refining Techniques and Processes

Silver refining is a crucial process in the precious metals industry, aimed at purifying silver to remove impurities and achieve high-quality results. This article explores various techniques and processes involved in silver refining, emphasizing key methods, equipment, and considerations for effective refinement.

Overview of Silver Refining

Silver refining involves purifying silver to achieve a high level of purity, making it suitable for various applications, from jewelry to electronics. The refining process helps eliminate contaminants and ensures the silver meets industry standards.

Key Techniques in Silver Refining

Several techniques are used in silver refining, each with its own advantages and applications. These methods vary based on the initial quality of the silver and the desired purity level.

Chemical Silver Refining

Chemical refining is one of the most common methods used to purify silver. This technique involves using chemicals to dissolve impurities and separate them from the silver.

Acid Leaching

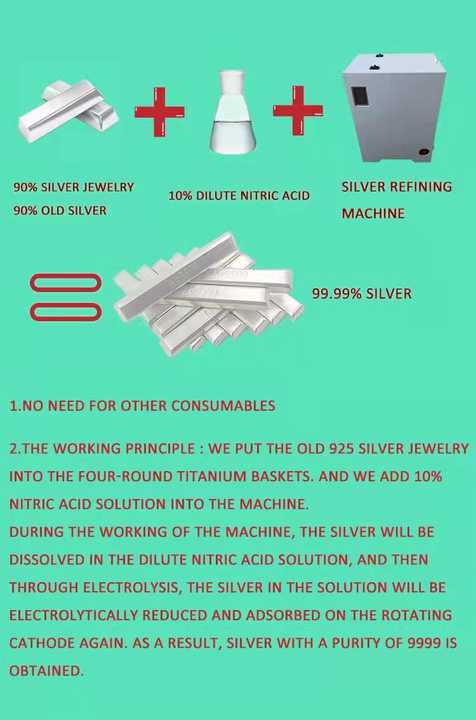

Acid leaching is a prevalent method where silver ore or scrap is treated with acids such as nitric acid. The acid reacts with impurities, leaving behind a solution containing silver. The silver is then recovered through processes like precipitation or electrolysis. This method is effective for refining both high-grade and low-grade silver ores.

Aqua Regia Process

The aqua regia process involves dissolving silver in a mixture of hydrochloric and nitric acids. Aqua regia, a powerful acid, dissolves the silver and allows impurities to be separated. After dissolution, the silver is recovered by reducing the solution with chemicals such as sodium metabisulfite.

Electrolytic Refining

Electrolytic refining is another widely used method, particularly for high-purity silver. This technique involves using an electrolytic cell where silver is dissolved and then redeposited onto a cathode.

Electrolysis Process

In the electrolytic refining process, silver is dissolved in an electrolyte solution, typically containing silver nitrate. An electric current is passed through the solution, causing silver ions to migrate to a cathode where they are deposited as pure silver. This method is highly effective for achieving silver with very high purity.

Advantages of Electrolytic Refining

Electrolytic refining offers several benefits, including high purity levels, minimal chemical use, and the ability to handle large quantities of silver. It is especially useful for refining silver from scrap or dore bars.

Equipment Used in Silver Refining

Several pieces of equipment are essential for silver refining, each playing a specific role in the purification process.

Furnaces

Furnaces are used for melting and casting silver, as well as for some refining processes. They must be capable of reaching high temperatures and maintaining stable conditions. Different types of furnaces, such as electric and gas-powered models, are used based on the scale and nature of the refining operation.

Electrolytic Cells

Electrolytic cells are crucial for the electrolytic refining process. These cells consist of an anode, cathode, and electrolyte solution. The silver is dissolved at the anode and redeposited at the cathode during electrolysis.

Filtration Systems

Filtration systems are used to remove impurities from solutions during the refining process. They ensure that only pure silver is recovered and that contaminants are effectively removed from the mixture.

Considerations in Silver Refining

Effective silver refining requires careful consideration of several factors to ensure optimal results and high-quality output.

Purity Requirements

The desired purity level of the silver will dictate the choice of refining method. Different techniques offer varying levels of purity, with electrolytic refining generally achieving the highest standards.

Environmental Impact

The refining process should be managed with environmental considerations in mind. Proper handling and disposal of chemicals, as well as waste management, are essential to minimize the impact on the environment.

Cost and Efficiency

The cost and efficiency of silver refining processes can vary. Methods like electrolytic refining may involve higher initial costs but offer long-term benefits in terms of purity and efficiency. Balancing these factors is important for optimizing refining operations.

Silver refining is a critical process for producing high-quality silver from various sources. By employing techniques such as chemical refining and electrolytic refining, and utilizing the appropriate equipment, refiners can achieve excellent results. Understanding the key methods, equipment, and considerations involved in silver refining helps ensure effective purification and high-quality output. Whether refining silver for jewelry, industrial applications, or investment purposes, selecting the right approach is essential for achieving optimal results.