Silver Smelting Ore

Understanding Silver Smelting Ore: A Comprehensive Guide

Silver smelting ore is a critical component in the extraction process of silver from its natural form. This guide aims to provide a detailed overview of the methods and technologies used in the smelting of silver ore, focusing on the latest advancements and best practices in the industry. Whether you’re a seasoned metallurgist or just starting to explore the fascinating world of silver processing, this article will serve as your go-to resource.

Silver Smelting Ore Preparation

Before the actual smelting process begins, silver smelting ore must undergo a series of preparatory steps to ensure optimal efficiency and output. These steps typically include crushing, grinding, and concentrating the ore. FRT Machinery offers state-of-the-art equipment designed specifically for these tasks, ensuring that the ore is ready for the smelting stage. By using FRT Machinery’s advanced ore preparation systems, operators can significantly enhance the purity and quality of the final silver product.

Techniques for Processing Silver Smelting Ore

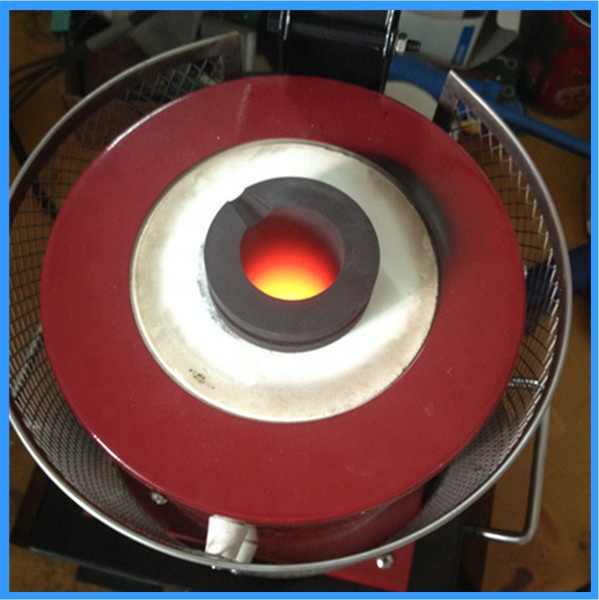

The core of silver smelting lies in the techniques employed during the processing phase. Common methods include pyrometallurgy and hydrometallurgy. Pyrometallurgy involves high-temperature processes such as roasting and smelting, which help in separating silver from other elements present in the smelting ore. Hydrometallurgy, on the other hand, uses aqueous solutions to leach out silver from the ore. FRT Machinery’s innovative furnaces and leaching tanks facilitate both processes efficiently, adapting to the specific requirements of different ores.

Environmental Considerations in Silver Smelting Ore Treatment

One of the significant challenges associated with silver smelting ore treatment is its environmental impact. Processes like roasting and smelting release harmful gases and residues if not managed properly. FRT Machinery addresses these concerns by integrating eco-friendly technologies into their smelting equipment. These include emission control systems and waste heat recovery units, which not only reduce pollution but also improve energy efficiency in the smelting plant.

Cost-Efficient Approaches to Silver Smelting Ore Extraction

Cost-efficiency is a key consideration in the smelting industry, particularly when dealing with silver smelting ore. To minimize operational costs while maximizing yield, FRT Machinery has developed cost-effective solutions tailored to the unique needs of silver extraction. Their automated systems reduce labor costs, while their optimized designs ensure lower energy consumption without compromising on performance. This makes them ideal for both small-scale operations and large industrial plants looking to streamline their smelting processes.

Maintaining Quality in Silver Smelting Ore Production

Maintaining the quality of silver produced from smelting ore is essential for ensuring customer satisfaction and maintaining market competitiveness. FRT Machinery’s rigorous quality control measures, implemented throughout the smelting process, guarantee that the final product meets international standards. From initial ore processing to the final refining stages, every step is closely monitored to produce pure, high-grade silver.

Future Trends in Silver Smelting Ore Technology

As technology advances, so does the methodology behind silver smelting ore processing. Future trends point towards more sustainable and technologically advanced solutions. FRT Machinery is at the forefront of this innovation, continually researching and developing new methods to improve the efficiency and sustainability of silver smelting. With a focus on automation, artificial intelligence, and green technology, they aim to set new benchmarks in the industry.

By following these guidelines and utilizing the latest technology from FRT Machinery, operators can ensure a smooth, efficient, and environmentally responsible process for smelting silver ore. Whether it’s enhancing productivity, reducing costs, or meeting stringent environmental regulations, FRT Machinery provides comprehensive solutions tailored to meet the diverse needs of modern smelting operations.