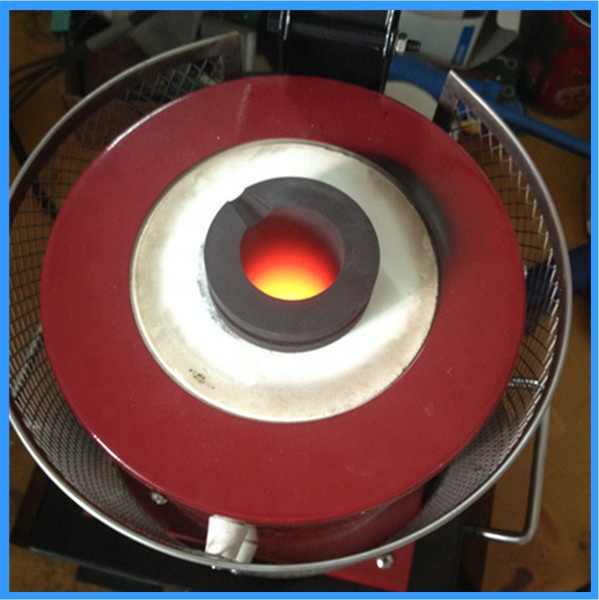

silver smelting pot

Silver Smelting Pot A Vital Tool for High-Quality Silver Production

The silver smelting pot is an essential tool in the silver refining and smelting process, playing a critical role in the melting and casting of silver. This versatile piece of equipment helps to achieve the high temperatures required for smelting and ensures the efficient processing of silver. In this article, we will explore the importance of the silver smelting pot, its various types, and how to use it effectively to obtain high-quality silver products.

Understanding the Silver Smelting Pot

A silver smelting pot is a container used to hold and heat molten silver during the smelting process. Its primary function is to withstand high temperatures and allow for the even melting of silver scrap or ore. The choice of a smelting pot can significantly impact the efficiency and quality of the silver refining process.

Types of Silver Smelting Pots

1. Crucibles

Crucibles are the most common type of smelting pot used in the silver refining process. They are designed to withstand extreme temperatures and are available in various materials and sizes.

- Material: Crucibles are typically made from heat-resistant materials such as graphite, clay, or ceramic. Graphite crucibles are particularly popular due to their excellent thermal conductivity and resistance to thermal shock.

- Design: Crucibles come in different shapes and sizes, including round and cylindrical, to accommodate various quantities of silver and types of furnaces.

2. Melting Pots

Melting pots are similar to crucibles but are often used for smaller batches or specific applications. They can be used with a variety of heating methods, including electric furnaces or gas torches.

- Material: Melting pots are usually made from durable metals or alloys that can withstand high temperatures and repeated use.

- Design: These pots often feature handles or grips for easy handling and pouring of molten silver.

3. Electric Smelting Pots

Electric smelting pots are designed for use with electric furnaces and offer precise temperature control and efficient heating.

- Material: These pots are generally made from high-quality metals or alloys that can endure the intense heat produced by electric furnaces.

- Design: They are often equipped with features that allow for easy monitoring of temperature and control of the smelting process.

Using a Silver Smelting Pot

1. Preparation

- Cleaning: Ensure that the smelting pot is clean and free from any residues or contaminants. This helps prevent any unwanted reactions or impurities from affecting the silver.

- Preheating (Optional): Preheating the pot can help to reduce thermal shock and improve the efficiency of the melting process.

2. Melting Silver

- Loading the Pot: Place the silver scrap or ore into the smelting pot. If using flux, add it to the pot to assist in removing impurities and to help the silver melt more evenly.

- Heating: Heat the pot using the appropriate method, whether it is an electric furnace, gas torch, or another heating source. The temperature should be high enough to melt the silver, typically around 962°C (1,764°F).

3. Pouring and Handling

- Pouring: Once the silver is molten, carefully pour it into molds to form ingots, bars, or other desired shapes. Use appropriate tools to handle the hot smelting pot and prevent spills.

- Cooling: Allow the molten silver to cool and solidify in the molds. Once solidified, remove the silver and inspect it for quality and purity.

Benefits of Using a Silver Smelting Pot

- Temperature Control: A quality smelting pot allows for precise temperature control, which is crucial for achieving the desired quality of silver.

- Efficiency: The use of a smelting pot streamlines the melting and casting process, improving overall efficiency.

- Durability: High-quality smelting pots are designed to withstand repeated use and high temperatures, making them a long-lasting investment.

Considerations and Challenges

- Material Compatibility: Ensure that the smelting pot is compatible with the type of heating method and silver being processed to avoid damage or contamination.

- Safety Precautions: Always use safety gear and follow proper handling procedures to prevent accidents or injuries during the smelting process.

- Maintenance: Regular maintenance and cleaning of the smelting pot are necessary to ensure its longevity and optimal performance.

The silver smelting pot is a crucial tool in the silver refining and smelting process, offering precise temperature control and efficient melting of silver. By understanding the different types of smelting pots and how to use them effectively, you can ensure high-quality results in your silver processing endeavors. Whether you are producing silver ingots, bars, or other forms, selecting the right smelting pot and following best practices will lead to successful and efficient silver refining.