Silver Smelting Tools

Introduction to Silver Smelting Tools: Precision and Craftsmanship by FRT Machinery

In the intricate world of metalworking, silver smelting stands out as a process that demands precision, expertise, and high-quality tools. FRT Machinery, renowned for its commitment to excellence, offers a comprehensive range of silver smelting tools designed to meet the rigorous standards of both artisans and industrial operations. This article explores the essential tools required for silver smelting, highlighting their features and benefits.

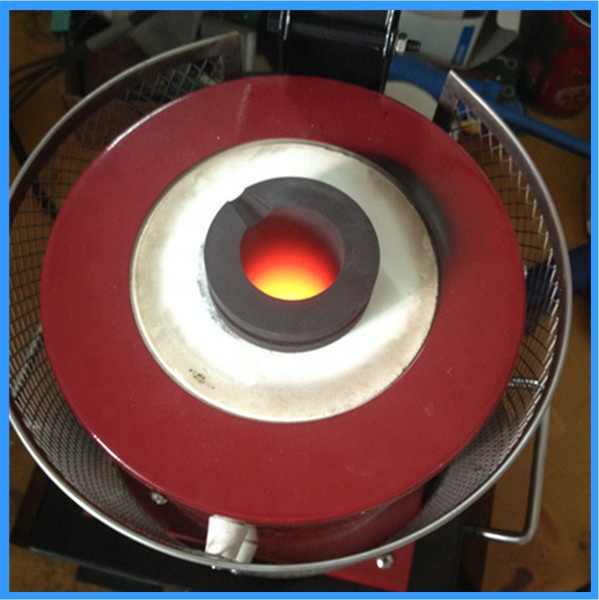

Silver Smelting Furnaces: The Heart of the Process

The furnace is arguably the most critical piece of equipment in silver smelting. FRT Machinery’s furnaces are engineered with advanced insulation materials and efficient heating elements, ensuring uniform heat distribution and minimal energy consumption. These furnaces can reach temperatures exceeding 1000°C, necessary for melting silver efficiently. With precise temperature control systems, operators can achieve optimal conditions for smelting, refining, and casting silver into various forms.

Silver Smelting Crucibles: Durability and Safety

Crucibles are used to contain molten silver during the smelting process. FRT Machinery provides crucibles made from high-purity graphite, which can withstand extreme temperatures without degrading. These crucibles also offer excellent thermal shock resistance, making them ideal for repeated use in the demanding environment of a smelting operation. Safety is paramount, and these crucibles are designed with ergonomic handles, allowing for safe handling even when fully loaded with molten metal.

Silver Smelting Flasks: Precision Casting

For casting silver into specific shapes, flasks play a crucial role. FRT Machinery’s flasks are designed to hold molds securely while allowing for easy pouring of molten silver. Made from durable materials, these flasks ensure accurate casting every time. They come in various sizes to accommodate different casting requirements, from intricate jewelry pieces to larger industrial components. The precision of these flasks contributes significantly to the quality and consistency of the final products.

Silver Smelting Tongs and Handling Equipment: Control and Efficiency

Handling hot materials safely requires specialized tools. FRT Machinery offers a range of tongs and other handling equipment specifically designed for silver smelting applications. These tools feature heat-resistant materials and comfortable grips, enabling workers to manipulate crucibles, molds, and other hot items with confidence. Enhanced control leads to increased efficiency and safety in the smelting process.

Silver Smelting Ventilation Systems: Protecting Health and Environment

Exposure to fumes during silver smelting can pose health risks if not properly managed. FRT Machinery emphasizes the importance of ventilation systems that effectively capture and filter harmful fumes. These systems help maintain a clean working environment, protecting the health of operators and complying with environmental regulations. By investing in robust ventilation solutions, businesses can ensure a safer workspace while contributing positively to sustainability efforts.

Silver Smelting Testing Kits: Ensuring Quality

To guarantee the purity and quality of the smelted silver, testing is essential. FRT Machinery provides comprehensive testing kits that allow for quick and accurate analysis of silver content. These kits include necessary reagents and instruments for performing assays on-site, enabling immediate adjustments to the smelting process if needed. Quality assurance through regular testing enhances the value and reliability of the final product.

By choosing FRT Machinery for your silver smelting tool needs, you’re investing in technology that combines innovation with practicality. Whether you’re a small artisan looking to refine your craft or a large-scale manufacturer seeking to streamline production, our tools are designed to meet your unique requirements. Experience the difference that precision and craftsmanship make in every step of the smelting process.