silver smelting

Introduction to Silver Smelting

Silver smelting is a vital process in the precious metals industry, focused on extracting and refining silver from ore. This process involves several stages, each designed to separate silver from other elements and impurities, ultimately producing high-quality silver ready for various applications. Understanding silver smelting is essential for professionals in the field as it ensures the efficient and effective production of pure silver.

The Basics of Silver Smelting

Silver smelting is the process of heating silver ore to high temperatures in a furnace to extract pure silver. This stage follows the initial extraction of ore and preparation for smelting. The goal is to convert the silver content within the ore into a molten state, which can then be refined and purified.

Ore Preparation for Smelting

The first step in silver smelting involves preparing the ore. This includes crushing and grinding the silver ore to liberate the silver particles from surrounding materials. The ore is then mixed with fluxes, such as lead or soda ash, which help in separating the silver from other metals and impurities during the smelting process.

Smelting Process

The core of the silver smelting process is the heating of the ore mixture in a furnace. The ore and fluxes are subjected to high temperatures, typically between 1,000 and 1,200 degrees Celsius (1,832 and 2,192 degrees Fahrenheit). During this heating phase, the silver melts and separates from other elements, forming a molten metal that can be easily collected and further processed.

Techniques in Silver Smelting

Various techniques can be used in silver smelting, each offering different advantages depending on the specific requirements and characteristics of the ore.

Traditional Smelting Methods

Traditional silver smelting methods often involve the use of a blast furnace or a reverberatory furnace. These methods have been used for centuries and are effective in extracting silver from ores with a high lead content. The traditional techniques rely on the use of high temperatures and specific fluxes to achieve optimal separation of silver.

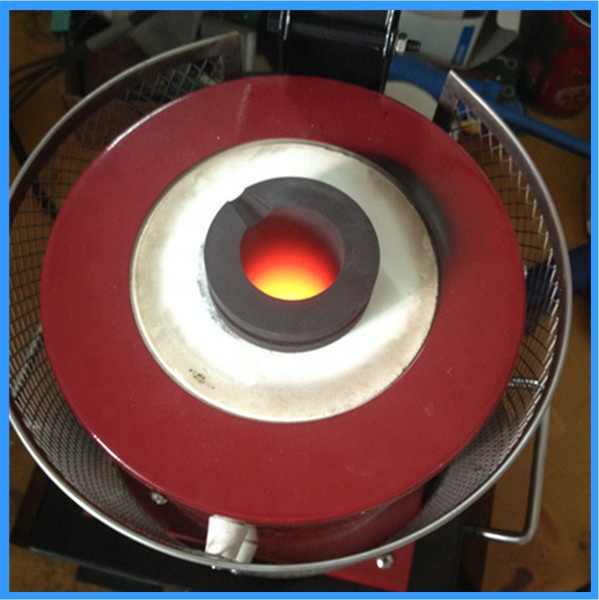

Modern Smelting Technologies

Modern silver smelting technologies have advanced significantly, incorporating innovative techniques and equipment. One such technology is the induction furnace, which uses electromagnetic induction to heat the ore mixture. This method offers precise temperature control and improved efficiency compared to traditional methods. Another advancement is the use of automated systems to monitor and control the smelting process, enhancing consistency and safety.

Refining Silver After Smelting

Once the smelting process is complete, the next step is refining the silver to achieve the desired purity. This stage involves removing any remaining impurities and further purifying the molten silver.

Electrolytic Refining

Electrolytic refining is a common method used after silver smelting. In this process, the smelted silver is dissolved in an electrolytic solution and then re-deposited onto a cathode. The impurities are left behind in the solution, resulting in high-purity silver that meets industry standards.

Chemical Refining

Chemical refining is another method employed to purify silver after smelting. This technique uses chemicals, such as nitric acid, to dissolve and remove impurities from the silver. Chemical refining is often used in combination with electrolytic refining to achieve the highest levels of purity.

Applications of Smelted Silver

Smelted silver has a wide range of applications across various industries. Its purity and quality make it suitable for use in jewelry, electronics, medical devices, and industrial components. The versatility of smelted silver highlights the importance of effective smelting and refining processes in producing valuable materials for diverse uses.

Silver smelting is a crucial process in the production of high-quality silver. From ore preparation and smelting to refining, each stage is designed to ensure that the final product meets industry standards and is suitable for various applications. Understanding the silver smelting process is essential for professionals in the precious metals industry, as it guarantees the efficient and effective production of pure silver.