smelter price precious metal

The price of a smelter for precious metal can significantly impact your overall investment in metal refining. Understanding the factors that influence smelter prices and how to evaluate different options can help you make informed decisions and optimize your refining operations.

Factors Influencing Smelter Price for Precious Metal

When considering the price of a smelter for precious metals, several factors come into play. These factors can affect both the initial cost and the long-term operational expenses.

Type of Smelter

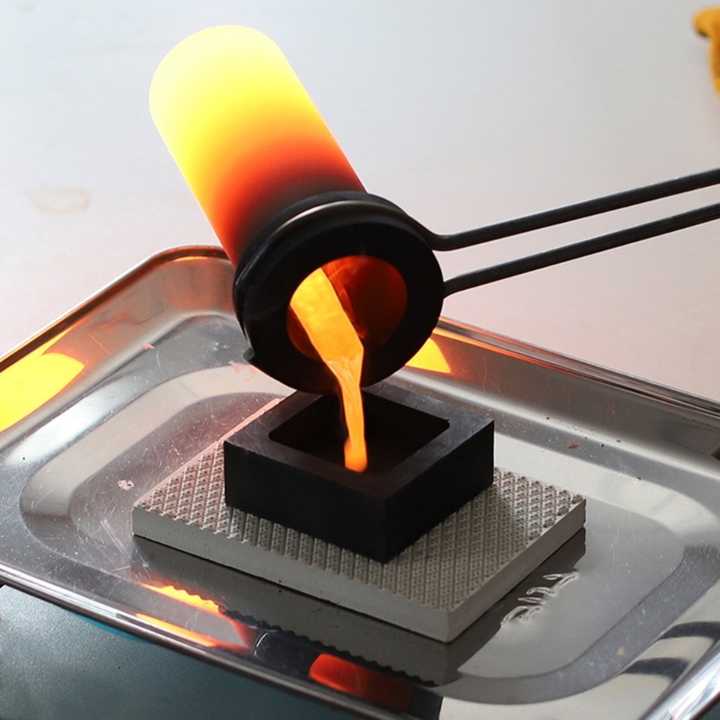

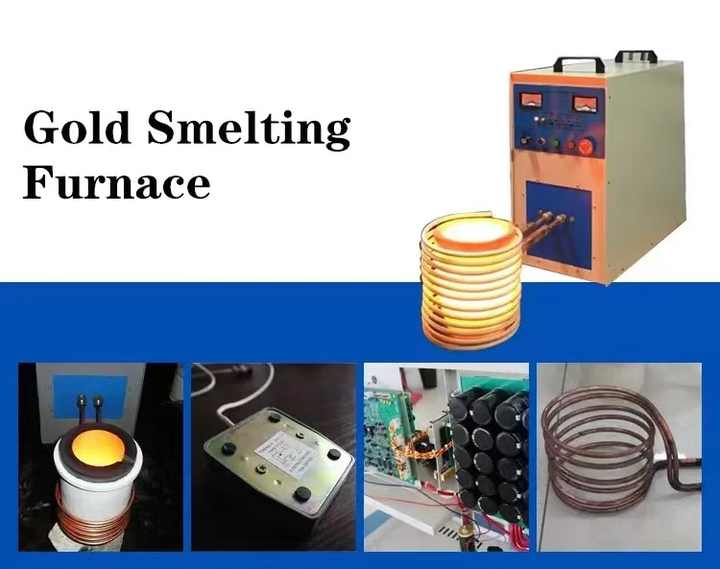

The type of smelter is a primary factor affecting its price. Different smelters are designed for various applications and capacities:

- Electric Smelters: These typically have higher initial costs due to advanced technology and precise temperature control.

- Gas-Powered Smelters: These often have lower upfront costs but may incur higher operational costs depending on fuel prices.

- Induction Smelters: These provide high efficiency and precise control, usually at a premium price.

Each type has its advantages and cost implications, which should be considered based on your specific needs and budget.

Size and Capacity

The size and capacity of the smelter also impact its price. Larger smelters designed to handle higher volumes of precious metals tend to cost more than smaller, laboratory-scale units. Consider the scale of your operations to choose a smelter that fits your requirements without overextending your budget.

Material and Build Quality

The quality of materials used in constructing the smelter affects its price. High-quality materials and construction methods enhance durability and performance but come at a higher cost. Investing in well-built equipment can lead to better long-term reliability and lower maintenance costs.

Evaluating Smelter Prices for Precious Metals

To make an informed decision, it’s essential to evaluate smelter prices comprehensively. Here are some steps to help you in this process:

Research and Compare Options

Begin by researching different smelters available in the market. Compare the features, capacities, and prices of various models. Look for reviews and testimonials from other users to assess performance and reliability. This research will give you a clearer understanding of what to expect in terms of price and value.

Consider Total Cost of Ownership

The initial purchase price is only one part of the total cost of owning a smelter. Consider additional expenses such as installation, maintenance, and operational costs. For instance, while electric smelters may have higher upfront costs, they could offer savings in energy efficiency over time. Assessing the total cost of ownership will help you make a more informed decision.

Evaluate Long-Term Value

Investing in a higher-priced smelter may provide better performance and longer service life, which can be more cost-effective in the long run. Consider the potential for increased productivity, lower maintenance costs, and improved quality of the refined metal. Weighing these factors against the initial price will help you determine the best value for your investment.

Key Considerations When Purchasing a Smelter

When purchasing a smelter for precious metals, there are several key considerations to keep in mind:

Manufacturer Reputation and Support

Choose a smelter from a reputable manufacturer known for quality and reliable support. A well-established manufacturer is more likely to offer better customer service, warranties, and technical support. This can be crucial for resolving issues and ensuring the smooth operation of your smelter.

Customization and Features

Some smelters offer customization options and additional features that can enhance their functionality. Consider whether these features align with your needs and if they justify any additional costs. Customization options might include advanced controls, enhanced safety features, or specific design modifications.

Energy Efficiency

Energy efficiency is an important factor that affects both the operational cost and the environmental impact of your smelting operations. Evaluate the energy consumption of different smelters and consider models that offer better efficiency and lower operating costs.

Finding the Right Smelter Price for Your Needs

Finding the right smelter price for your precious metal refining needs requires careful consideration of various factors. Start by defining your requirements, including the type of metal, scale of operation, and budget constraints. Conduct thorough research and compare different options to ensure you choose a smelter that provides the best balance of price, performance, and value.

Negotiating and Purchasing

Once you have identified a suitable smelter, consider negotiating with the supplier to obtain the best possible price. Suppliers may offer discounts or financing options based on your purchase volume or commitment. Be sure to review the terms and conditions of the purchase agreement carefully.

The price of a smelter for precious metal is a crucial factor in your overall refining investment. By understanding the factors that influence smelter prices and evaluating your options thoroughly, you can make informed decisions that align with your budget and operational needs. Whether you are looking for a small-scale laboratory smelter or a large industrial unit, careful consideration and research will help you find the best smelter price for your precious metal refining operations.