Smelting Fluxes For Silver Lead

Understanding Smelting Fluxes for Silver Lead

Smelting fluxes play a pivotal role in the metallurgical processes used to extract and purify metals from their ores. In the context of silver and lead smelting, these fluxes are essential for facilitating the separation of valuable metals from unwanted impurities. FRT Machinery, a leader in providing advanced solutions for the metallurgical industry, offers insights into the types, applications, and benefits of using smelting fluxes specifically designed for silver and lead.

Types of Smelting Fluxes for Silver Lead

When it comes to processing silver and lead ores, selecting the right type of smelting flux can significantly impact the efficiency and effectiveness of the smelting process. Commonly used smelting fluxes for silver lead include silica, limestone, and lime. Each has its unique properties that make it suitable for specific conditions and requirements during the smelting process.

Silica, being one of the most common fluxes, helps in reducing the melting point of the slag, making it easier to separate from the molten metal. Limestone and lime, on the other hand, are used to remove sulfur and other non-metallic impurities, enhancing the purity of the final product.

Benefits of Using Smelting Fluxes for Silver Lead

The use of smelting fluxes brings several advantages to the table when dealing with silver and lead ores. Firstly, these fluxes reduce the melting temperature of the charge material, thereby decreasing energy consumption and operational costs. Secondly, they improve the fluidity of the slag, which is crucial for effective separation from the molten metal. This ensures a higher yield of pure silver and lead, contributing positively to the overall efficiency of the smelting operation.

Moreover, smelting fluxes help in controlling the chemistry of the slag, which is essential for maintaining the quality of the final product. By choosing the appropriate flux, manufacturers can achieve optimal conditions for smelting, leading to better environmental outcomes and economic benefits.

Applications of Smelting Fluxes in Silver Lead Processing

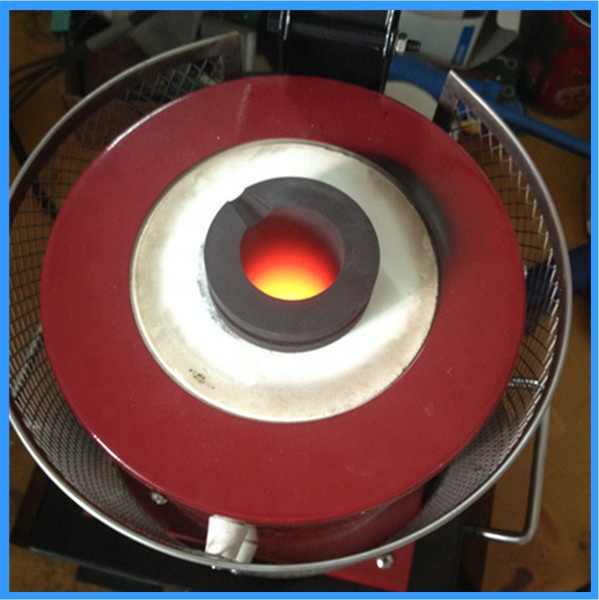

In the silver and lead smelting industry, smelting fluxes find extensive application across various stages of the production process. During the initial smelting phase, fluxes are added to the furnace to aid in the formation of slag. This slag, composed mainly of non-metallic materials, floats on top of the molten metal, allowing for easy removal and ensuring the purity of the metal underneath.

For secondary refining operations, where further purification of the metal is required, specialized fluxes may be employed. These fluxes assist in removing any remaining impurities, contributing to the production of high-purity silver and lead products.

Choosing the Right Smelting Flux for Silver Lead

Selecting the appropriate smelting flux for your silver and lead processing needs requires careful consideration of several factors. These include the chemical composition of the ore, the desired purity level of the end product, and the specific requirements of your smelting process. Consulting with experts like those at FRT Machinery can provide tailored advice on which fluxes will best suit your operations.

FRT Machinery offers a range of flux options designed to meet the diverse needs of silver and lead smelters. Their team can guide you through the selection process, ensuring that you choose the most suitable flux for your specific application, thereby maximizing productivity and profitability.

Proper Handling and Storage of Smelting Fluxes for Silver Lead

To ensure the optimal performance of smelting fluxes, proper handling and storage practices must be followed. Exposure to moisture can degrade the quality of fluxes, affecting their efficacy during the smelting process. Therefore, storing fluxes in a dry environment away from direct sunlight is crucial.

Additionally, regular inspections and maintenance of storage facilities can prevent contamination and degradation of the flux materials. Following these guidelines not only extends the shelf life of the fluxes but also maintains their effectiveness in the smelting process.

By understanding the importance of smelting fluxes and adhering to best practices in their selection, application, and maintenance, silver and lead smelters can achieve superior results in their operations. FRT Machinery remains committed to supporting these efforts through innovative solutions and expert guidance.