Smelting Fluxes For Silver

Understanding Smelting Fluxes for Silver

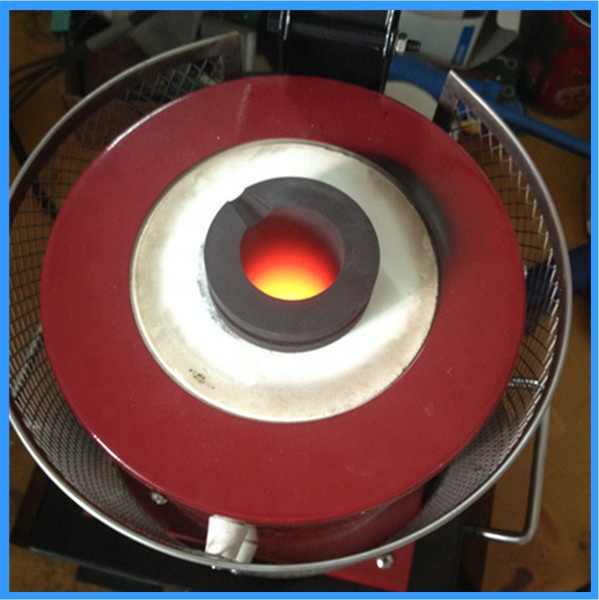

Silver smelting is a process that has been refined over centuries to extract this precious metal from its ores. Essential to this process aresmelting fluxes for silver, which play a critical role in purifying silver and separating it from impurities. In this article, we delve into the intricacies of using smelting fluxes for silver, exploring their composition, application, and benefits. FRT Machinery, a leading provider of metallurgical solutions, shares insights on how these fluxes enhance the efficiency and effectiveness of silver smelting processes.

Types of Smelting Fluxes for Silver

The choice of smelting flux depends largely on the specific conditions of the smelting process and the nature of the ore being treated. Commonly usedsmelting fluxes for silverinclude silica, lime, and borax. Each type serves a unique function in the smelting process:

-Silica (SiO₂): Often used due to its ability to lower the melting point of slag, making it easier to separate from the molten silver.

-Lime (CaO): Helps in removing impurities by reacting with them to form compounds that can be easily removed as slag.

-Borax (Na₂B₄O₇·10H₂O): Known for its effectiveness in reducing the melting point of materials, making it particularly useful in small-scale operations where energy efficiency is crucial.

Benefits of Using Smelting Fluxes for Silver

Incorporatingsmelting fluxes for silveroffers several advantages over traditional smelting methods without fluxes. These benefits include:

-Enhanced Metal Recovery: By improving the separation between slag and molten silver, fluxes increase the yield of pure silver from the ore.

-Energy Efficiency: Lowering the melting point of the slag reduces the overall energy required for the smelting process, contributing to cost savings and environmental sustainability.

-Purity Improvement: The removal of impurities through the formation of slag leads to higher purity levels in the final silver product, enhancing its market value.

Application Methods of Smelting Fluxes for Silver

The application ofsmelting fluxes for silveris a precise science that requires careful consideration of factors such as the type of ore, the presence of other metals, and the desired purity level of the silver. At FRT Machinery, our experts recommend the following steps for optimal application:

1.Preparation: Ensure that the ore is properly crushed and prepared according to the specific requirements of the smelting process.

2.Flux Selection: Choose the most appropriate flux based on the characteristics of the ore and the desired outcome.

3.Mixing: Integrate the selected flux into the ore in the correct proportions to facilitate efficient smelting.

4.Smelting: Heat the mixture to the appropriate temperature, allowing the flux to perform its role in purifying the silver.

Troubleshooting Issues with Smelting Fluxes for Silver

Despite their many benefits,smelting fluxes for silvercan sometimes present challenges if not used correctly. Common issues include improper slag formation, which can lead to incomplete separation of impurities, and excessive energy consumption if the flux does not effectively reduce the melting point of the slag. Addressing these problems often involves adjusting the ratio of flux to ore or changing the type of flux used.

FRT Machinery offers comprehensive support in troubleshooting these issues, ensuring that your smelting processes are optimized for maximum efficiency and productivity.

Conclusion

The use ofsmelting fluxes for silveris indispensable in modern metallurgy, providing significant improvements in both the quality and quantity of silver produced. As technology advances, so too does the science behind smelting fluxes, opening up new possibilities for innovation and efficiency gains. FRT Machinery remains committed to staying at the forefront of these developments, providing state-of-the-art solutions that meet the evolving needs of the industry.