Smelting For Lead And Silver

Smelting for Lead and Silver: A Comprehensive Guide

Smelting for lead and silver is a process that has been refined over centuries, evolving from rudimentary methods to sophisticated techniques that maximize yield and efficiency. This article will delve into the intricacies of smelting these precious metals, highlighting key aspects such as preparation, furnace types, and environmental considerations. Whether you’re a seasoned metallurgist or new to the field, understanding the nuances of smelting can significantly enhance your operations.

Preparation of Ores for Lead and Silver Smelting

Before smelting can begin, it’s crucial to prepare the ores properly. This step involves crushing and grinding the raw materials to reduce them to a fine powder, which increases the surface area and facilitates better interaction with the smelting agents. FRT Machinery offers state-of-the-art ore processing equipment designed to efficiently handle various feed sizes and hardness levels, ensuring optimal preparation for the subsequent smelting process.

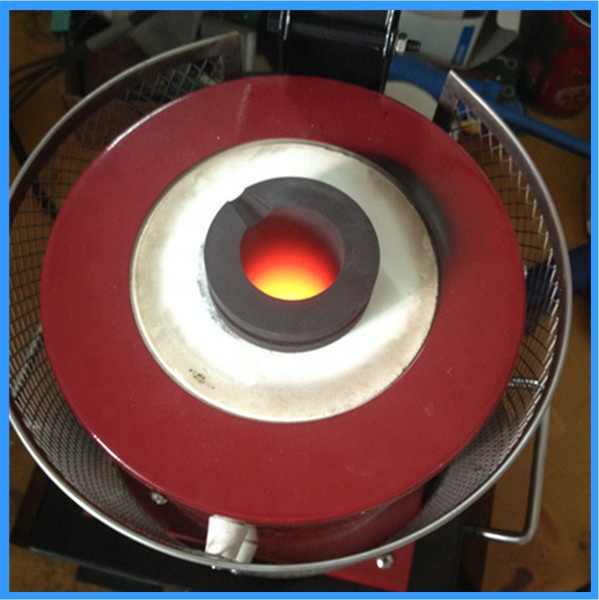

Furnace Types Used in Lead and Silver Smelting

The choice of furnace is critical in smelting lead and silver, as different furnaces offer varying degrees of efficiency and cost-effectiveness. Common types include blast furnaces, reverberatory furnaces, and electric arc furnaces. Each type has its advantages depending on the scale of operation and the specific requirements of the smelting process. FRT Machinery specializes in furnaces tailored for high-volume production while maintaining low operational costs and minimal environmental impact.

Environmental Considerations in Lead and Silver Smelting

Given the potential environmental hazards associated with smelting lead and silver, stringent measures must be implemented to mitigate pollution and ensure compliance with regulatory standards. These include capturing and treating flue gases to remove harmful pollutants, managing waste streams responsibly, and adopting cleaner technologies. FRT Machinery integrates advanced pollution control systems into their smelting solutions, helping industries minimize their ecological footprint without compromising productivity.

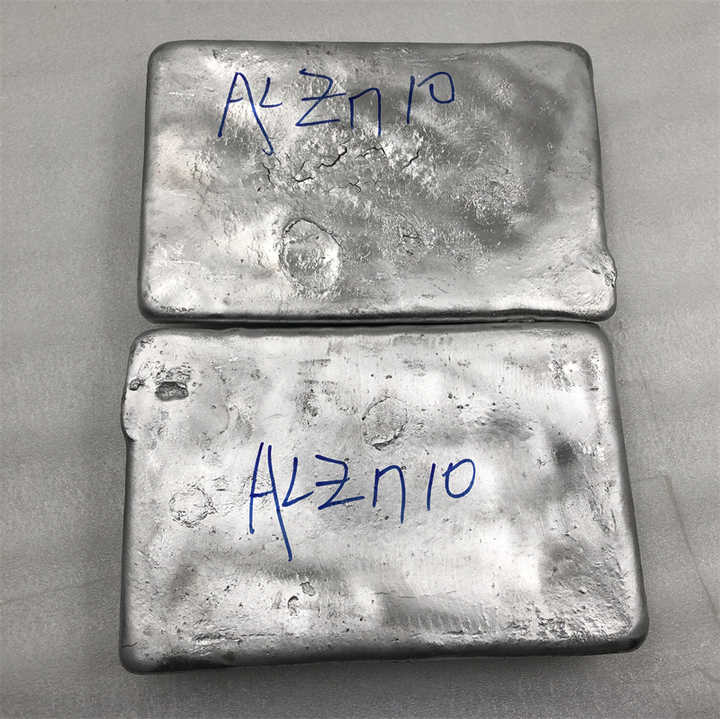

Techniques for Improving Efficiency in Lead and Silver Smelting

Efficiency in smelting is paramount for maximizing profitability and reducing energy consumption. Techniques such as preheating the charge material, optimizing the chemical composition of the slag, and employing continuous casting processes can significantly enhance smelting efficiency. FRT Machinery provides comprehensive solutions that incorporate these techniques, enabling operators to achieve higher yields with lower inputs, thus improving overall economic viability.

Safety Measures in Lead and Silver Smelting Operations

Safety is non-negotiable in smelting operations due to the high temperatures and hazardous materials involved. Implementing robust safety protocols, providing adequate training to personnel, and using protective gear are fundamental aspects of maintaining a safe working environment. FRT Machinery designs its equipment with built-in safety features and supports clients with training programs aimed at preventing accidents and ensuring worker well-being.

By focusing on these key areas—preparation, furnace selection, environmental stewardship, efficiency enhancement, and safety—industries can elevate their smelting practices for lead and silver. FRT Machinery stands committed to supporting these efforts through innovative technology and unparalleled expertise, driving the industry towards sustainable and profitable growth.