Smelting Gold And Silver

Smelting Gold and Silver: Mastering the Art of Precious Metal Extraction

Smelting Gold and Silver: The Foundation of Metal Extraction

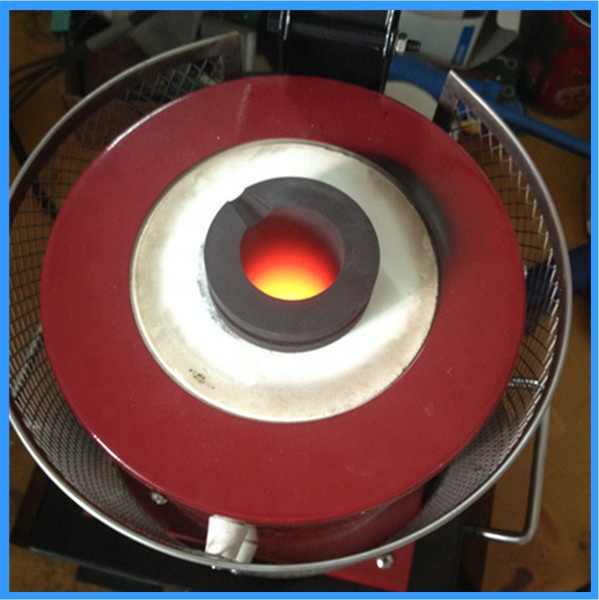

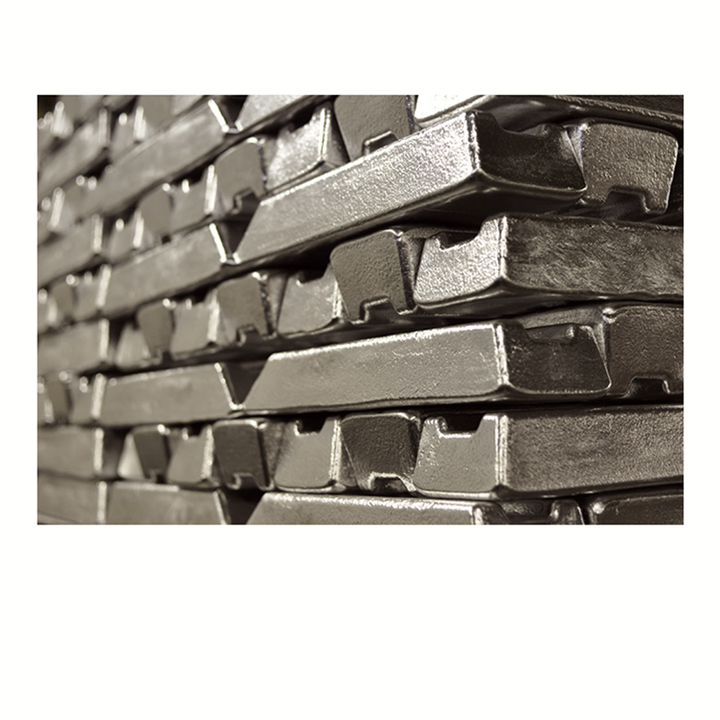

Smelting gold and silver is a process that has been refined over centuries, evolving from rudimentary techniques to sophisticated methodologies that maximize yield and efficiency. At its core, smelting involves heating ores or concentrates to a high temperature in the presence of flux and reductants. This process separates the precious metals from their ores, enabling them to be collected and further refined. FRT Machinery offers state-of-the-art smelting solutions designed to optimize this critical step, ensuring minimal loss and maximum purity.

The Crucial Role of Flux in Smelting Gold and Silver

Flux plays a crucial role in the smelting process of gold and silver. It helps to reduce the melting point of the ore mixture, making it easier to separate the precious metals from impurities. Common fluxes used in smelting include limestone and silica, which react with the non-metallic components of the ore, forming a slag that can be removed. FRT Machinery’s smelting furnaces are engineered to efficiently manage the addition of flux, enhancing the overall effectiveness of the smelting operation.

Innovative Technologies for Smelting Gold and Silver

Advancements in technology have significantly improved the smelting process for gold and silver, reducing environmental impact while increasing productivity. FRT Machinery has developed cutting-edge equipment that incorporates features such as precise temperature control and automated feeding systems. These innovations ensure a more consistent and controllable smelting process, leading to higher quality output and reduced operational costs. By leveraging the latest technologies, smelters can achieve superior results with less waste and energy consumption.

Safety Considerations in Smelting Gold and Silver

Safety is paramount when dealing with the high temperatures and hazardous materials involved in smelting gold and silver. Proper ventilation, personal protective equipment (PPE), and strict adherence to safety protocols are essential. FRT Machinery designs its smelting equipment with built-in safety features, such as emergency shut-off mechanisms and advanced filtration systems, to protect workers and the environment. Training employees on safe practices and maintaining equipment regularly are also key aspects of a comprehensive safety program.

Environmental Impact of Smelting Gold and Silver

The environmental impact of smelting gold and silver cannot be overlooked. While necessary for extracting these valuable resources, the process can release harmful emissions if not properly managed. FRT Machinery addresses this challenge by integrating emission control technologies into its smelting solutions. These include scrubbers and filters that capture pollutants before they are released into the atmosphere. Additionally, recycling slag and other by-products reduces waste and enhances sustainability.

Future Trends in Smelting Gold and Silver

Looking ahead, the future of smelting gold and silver is likely to be shaped by continued technological innovation and stricter environmental regulations. FRT Machinery is committed to staying at the forefront of these developments, continually improving its offerings to meet the evolving needs of the industry. From developing more efficient processes to exploring alternative energy sources, the goal remains clear: to extract gold and silver with the highest possible standards of efficiency, safety, and environmental responsibility.

By focusing on these key areas, FRT Machinery ensures that smelting operations remain sustainable, profitable, and aligned with global best practices. Whether you’re a small-scale operator or part of a large industrial complex, embracing the latest advancements in smelting technology is crucial for success in today’s competitive market.