Smelting Old Gold And Silver Jewelry

Smelting Old Gold and Silver Jewelry: A Guide to Recapturing Value

The Basics of Smelting Old Gold and Silver Jewelry

Smelting old gold and silver jewelry is a process that has been practiced for centuries. This process involves heating these precious metals to their melting points so they can be separated from other materials and alloys. Whether you’re a jeweler looking to reuse precious metals or an individual interested in recycling family heirlooms, understanding the basics of smelting can help ensure safe and effective results.

Before beginning, it’s important to gather the necessary equipment. FRT Machinery offers high-quality furnaces designed specifically for smelting gold and silver. These furnaces provide precise temperature control, which is crucial for preventing overheating and potential loss of material. Additionally, safety gear such as heat-resistant gloves, goggles, and a respirator should always be worn when handling molten metals.

Preparing Your Jewelry for Smelting

The first step in preparing your jewelry for smelting is to carefully inspect each piece. Look for hallmarks or stamps that indicate the purity and type of metal. It’s also advisable to separate gold and silver pieces, as they require different temperatures for smelting. FRT Machinery recommends using a digital scale to weigh the items accurately, ensuring you know exactly how much metal you’re working with.

Once sorted, remove any non-metallic components like gemstones or plastics. These elements can contaminate the melt or release harmful gases during the smelting process. If stones are securely set and cannot be removed without damaging them, consider consulting with a professional who can extract them safely.

Choosing the Right Equipment for Smelting Old Gold and Silver Jewelry

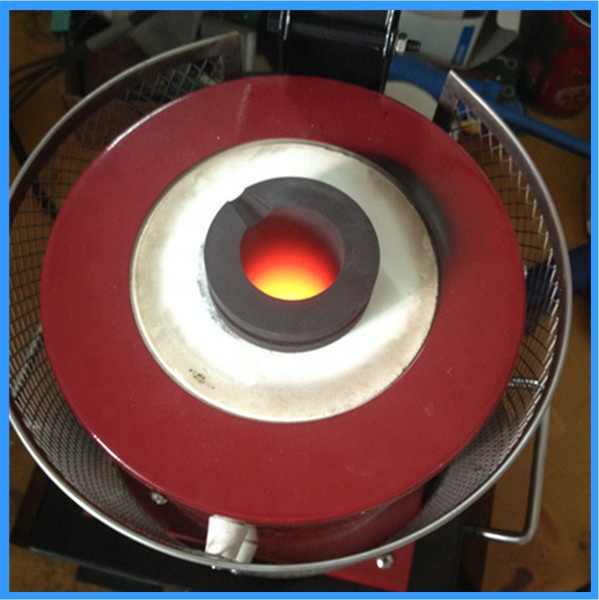

Selecting the right equipment is essential for successful smelting. FRT Machinery provides a range of options suitable for various scales of operation—from small-scale hobbyists to large commercial operations. Their furnaces feature advanced insulation materials that reduce energy consumption while maintaining consistent temperatures necessary for smelting gold and silver efficiently.

In addition to the furnace, you’ll need crucibles capable of withstanding extreme heat. FRT Machinery’s graphite crucibles are designed to handle multiple uses without compromising performance. Other tools like tongs, skimmers, and pouring spouts will also be useful during the smelting process.

Safety Considerations When Smelting Old Gold and Silver Jewelry

Safety must always come first when dealing with molten metals. Ensure your workspace is well-ventilated to avoid inhaling fumes produced during smelting. Always wear appropriate protective gear, including long sleeves, pants, closed-toe shoes, and face shields. Keep a fire extinguisher nearby in case of emergencies.

FRT Machinery emphasizes the importance of following manufacturer guidelines for operating their equipment. Regular maintenance checks and adherence to recommended procedures can prevent accidents and prolong the lifespan of your smelting setup.

Tips for Achieving High-Quality Results

To achieve the best possible outcome from your smelting efforts, consider these tips:

-Purify the Metal: After smelting, use fluxes or refining agents to remove impurities from the molten metal. FRT Machinery suggests using borax for silver and silica for gold.

-Control the Temperature: Maintaining the correct temperature is key to avoiding oxidation and ensuring a smooth, clean melt. FRT Machinery’s furnaces make this easy with their intuitive temperature controls.

-Pour Carefully: When transferring the molten metal into molds, move slowly and steadily to minimize air exposure and prevent splashing.

Conclusion on Smelting Old Gold and Silver Jewelry

Smelting old gold and silver jewelry can be both rewarding and profitable when done correctly. By investing in quality equipment from FRT Machinery and adhering to best practices, you can transform unwanted jewelry into valuable raw materials ready for new creations. Whether you’re a seasoned professional or just starting out, remember that patience, precision, and safety are the cornerstones of successful smelting.