Smelting Old Gold And Silver Jewelry

Smelting Old Gold and Silver Jewelry: A Guide to Recycling Precious Metals

When it comes to recycling precious metals, smelting old gold and silver jewelry is both an art and a science. This process not only helps in recovering valuable materials but also contributes significantly to sustainability efforts by reducing the need for mining new resources. Whether you’re a small-scale jeweler or a large recycling facility, understanding the intricacies of smelting can make all the difference in your operations.

The Importance of Pre-Smelting Preparation for Old Gold and Silver Jewelry

Before diving into the smelting process, proper preparation of old gold and silver jewelry is crucial. This step involves cleaning the pieces thoroughly to remove any dirt or residues that could contaminate the final product. Additionally, sorting the items based on their metal content is essential. Using specialized tools like X-ray fluorescence (XRF) analyzers from FRT Machinery ensures accurate identification and separation of gold, silver, and other alloys. By doing so, you set the foundation for a successful smelting process.

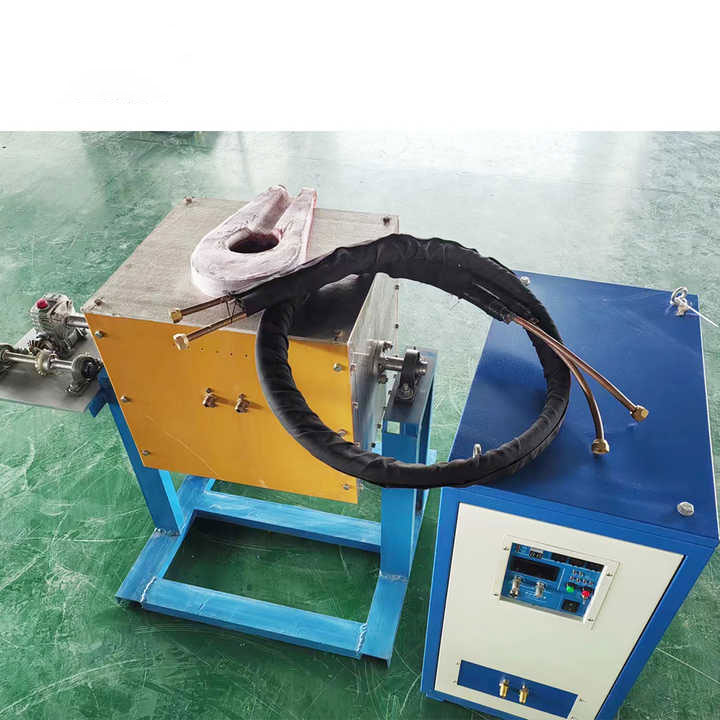

Selecting the Right Smelting Equipment for Old Gold and Silver Jewelry

Choosing the appropriate smelting equipment is vital for achieving optimal results when processing old gold and silver jewelry. FRT Machinery offers a range of high-quality smelters designed specifically for this purpose. These machines are equipped with features such as temperature control systems and efficient exhaust systems to ensure safe and effective melting. Whether you’re dealing with small batches or large volumes, there’s a FRT smelter suited to your needs.

Ensuring Environmental Compliance During the Smelting of Old Gold and Silver Jewelry

Environmental considerations play a significant role in the smelting of old gold and silver jewelry. The process must be carried out in a manner that minimizes pollution and adheres to local regulations. FRT Machinery’s advanced smelting solutions come with built-in environmental controls, including filters and scrubbers, which help reduce emissions. Regular maintenance and adherence to best practices further ensure that your operation remains environmentally friendly.

Tips for Efficient Melting of Old Gold and Silver Jewelry

To achieve the most efficient melting of old gold and silver jewelry, several tips can be applied. First, preheating the crucible reduces energy consumption and speeds up the melting process. Secondly, adding fluxes can help in removing impurities more effectively. Lastly, maintaining a consistent temperature throughout the smelting cycle ensures uniform melting and prevents overheating, which could damage the equipment. FRT Machinery provides comprehensive guidelines to help users optimize their processes.

Safety Measures When Smelting Old Gold and Silver Jewelry

Safety is paramount when working with high temperatures and hazardous materials. Always wear protective gear such as heat-resistant gloves, safety goggles, and respirators. Ensure that your workspace is well-ventilated and free from flammable substances. FRT Machinery’s smelting equipment is designed with safety in mind, featuring automatic shut-off mechanisms and other fail-safes to protect operators. Regular training sessions on safety protocols should also be conducted to keep everyone informed.

Innovations in Smelting Old Gold and Silver Jewelry

The field of smelting is continually evolving, with new technologies emerging to improve efficiency and sustainability. FRT Machinery invests heavily in research and development to bring innovative solutions to the market. From induction furnaces that offer precise temperature control to closed-loop systems that recycle cooling water, these advancements are revolutionizing how we approach the smelting of old gold and silver jewelry. Staying updated with these developments can give your business a competitive edge while contributing positively to environmental conservation efforts.