smelting silver

Smelting silver is an essential process in the extraction and purification of silver from its ores. This ancient practice has been refined over centuries, evolving into a sophisticated method used in various industries today. In this article, we will delve into the process of smelting silver, the techniques involved, and its applications across different sectors.

What is Smelting Silver?

Smelting silver is the process of extracting silver from its ore by applying heat and a reducing agent to drive off other elements, leaving behind the pure metal. This process is a crucial step in transforming raw silver ore into a form that can be further refined or used directly in various products. Smelting silver is not only important for producing pure silver but also for separating it from other metals that may be present in the ore.

The Smelting Silver Process Explained

The process of smelting silver involves several key steps, each designed to separate silver from other elements and produce a pure metal. Below, we explore the main stages in the smelting of silver.

1. Crushing and Concentration of Silver Ore

Before smelting silver, the ore must be prepared by crushing and concentrating it. The raw silver ore is crushed into a fine powder, which increases the surface area and makes it easier to extract the silver. The powdered ore is then concentrated using methods such as gravity separation or flotation, which help separate the heavier silver particles from lighter waste materials. This step is essential for improving the efficiency of the smelting process.

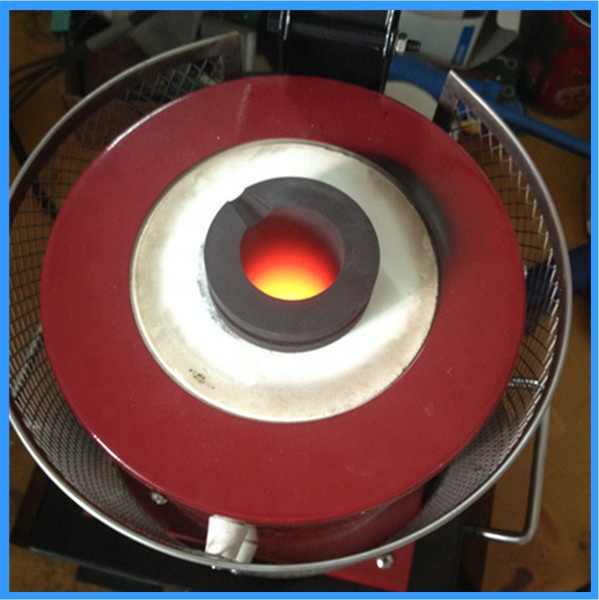

2. Smelting the Concentrated Silver Ore

Once the ore is concentrated, it is ready for smelting. The concentrated ore is placed in a furnace and heated to high temperatures, typically between 1,200 and 1,500 degrees Celsius. During smelting, a reducing agent, such as carbon, is added to the furnace to help separate the silver from other elements in the ore. As the ore melts, the silver is released and sinks to the bottom of the furnace, while impurities rise to the surface and form a layer of slag. This slag is removed, leaving behind molten silver.

3. Pouring and Cooling the Silver

After the smelting process, the molten silver is poured into molds to cool and solidify. This step transforms the silver into bars or other shapes that can be easily handled and further refined if necessary. The cooling process is carefully controlled to ensure the silver solidifies evenly, producing a high-quality final product.

4. Refining the Smelted Silver

While smelting silver removes many impurities, the metal may still contain trace amounts of other elements. To achieve a higher level of purity, the smelted silver may undergo further refining processes. Techniques such as electrolytic refining or the use of chemical baths can be employed to remove these remaining impurities, resulting in silver of the highest purity.

Importance of Smelting Silver

Smelting silver is a vital process in the production of pure silver, which is essential for various industries. By separating silver from other metals and impurities, smelting ensures that the final product meets industry standards for quality and purity. This process is particularly important in applications where the purity of silver is critical, such as in jewelry making, electronics, and the production of coins and bullion.

Moreover, smelting silver allows for the recovery of silver from ores that contain only small amounts of the metal. Without smelting, much of the silver in these ores would remain inaccessible, making the process crucial for maximizing the yield of silver from mining operations.

Applications of Smelted Silver

Smelted silver has a wide range of applications across different industries, thanks to its unique properties, such as conductivity, reflectivity, and resistance to corrosion. Below are some of the key applications of smelted silver.

1. Jewelry and Decorative Items

One of the most common uses of smelted silver is in the production of jewelry and decorative items. Silver’s luster, malleability, and resistance to tarnish make it a popular choice for crafting rings, necklaces, bracelets, and other adornments. Smelting silver ensures that the metal used in these products is pure and of the highest quality, enhancing the beauty and durability of the final piece.

2. Electronics and Electrical Components

Silver is widely used in the electronics industry due to its excellent conductivity and ability to form reliable connections. Smelted silver is used in various electronic components, such as switches, connectors, and circuit boards. The purity of the silver is crucial in these applications, as even small amounts of impurities can affect the performance and longevity of the electronic devices.

3. Coinage and Bullion

Silver has been used in coinage for centuries, and smelted silver continues to play a significant role in the production of coins and bullion. High-purity silver is essential for minting coins that meet legal standards and are suitable for investment purposes. Smelting silver ensures that the metal used in coins is free from impurities, resulting in high-quality products that are valued by collectors and investors alike.

4. Solar Energy and Photovoltaic Cells

In recent years, smelted silver has found applications in the renewable energy sector, particularly in the production of photovoltaic cells for solar panels. Silver’s conductive properties make it an ideal material for use in these cells, where it helps to efficiently convert sunlight into electricity. The purity of the silver used in solar cells is critical for maximizing the efficiency and output of the panels.

Environmental Considerations in Smelting Silver

While smelting silver is necessary for producing pure metal, the process can have environmental impacts. The energy required for smelting, as well as the emissions from the furnace, can contribute to greenhouse gas emissions and air pollution. Additionally, the chemicals used in smelting, such as fluxes and reducing agents, can pose environmental and health risks if not properly managed.

To address these concerns, the industry is increasingly focusing on developing more sustainable smelting practices. This includes using cleaner energy sources, improving waste management and recycling processes, and minimizing the use of hazardous chemicals in the smelting process.

Smelting silver is a fundamental process in the production of high-purity silver, which is essential for various applications, from jewelry and electronics to coinage and renewable energy. By understanding the smelting process and its importance, industry professionals can ensure that they are producing silver that meets the highest standards for quality and performance.

As the demand for silver continues to grow, the need for efficient, sustainable, and environmentally friendly smelting practices will also increase. Through continued innovation and improvement in smelting techniques, the industry can meet the needs of the market while minimizing its impact on the environment.