the process of refining gold

The process of refining gold is an ancient practice that has evolved over centuries, allowing for the production of pure gold from mined ores or recycled materials. This guide explores the various methods involved in refining gold and the steps necessary to produce high-purity gold.

Understanding the Process of Refining Gold

Refining gold involves removing impurities from the raw material to obtain pure gold. Gold in its natural state is rarely pure, often found mixed with other metals such as silver, copper, or zinc. The refining process isolates the gold from these base metals, allowing it to reach the desired purity level.

Common Methods of Refining Gold

Several methods are used to refine gold, each with its advantages and applications. The choice of method depends on the type of gold-bearing material and the desired level of purity.

Fire Assaying

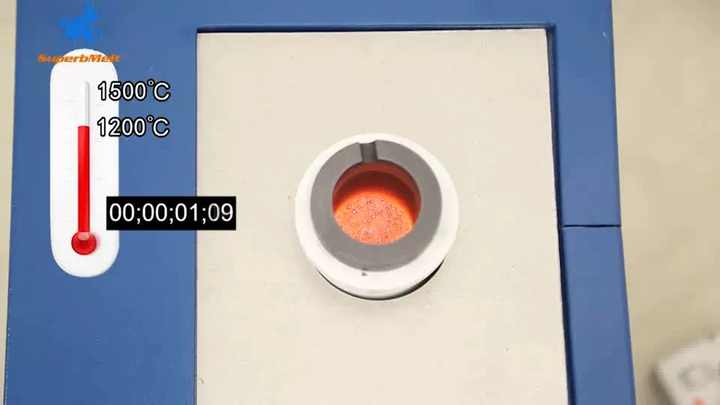

One of the oldest methods of refining gold is fire assaying, which involves melting the gold ore at high temperatures to separate the gold from other elements. This method relies on the fact that gold has a much higher melting point than most impurities, allowing for the separation of the metals.

In this process, the gold ore is melted in a furnace, and a chemical flux is added. The flux helps to bind the impurities, which can be removed as slag. The remaining gold is then collected and further processed to achieve higher purity.

Aqua Regia

Another widely used method in the process of refining gold is the aqua regia technique. Aqua regia is a mixture of hydrochloric acid and nitric acid, and it is used to dissolve gold and other metals in the ore. This method is particularly effective for refining gold from recycled materials like jewelry.

The solution dissolves the gold and base metals, and through a series of chemical reactions, pure gold is precipitated out of the solution. This method produces high-purity gold, often reaching 99.9% purity.

Electrolytic Refining

Electrolytic refining is a modern method used to refine gold on a larger industrial scale. This process involves the use of electricity to separate gold from other metals. A gold-rich solution is passed through an electrolytic cell, where gold ions are attracted to a cathode and deposited as pure gold.

This method is highly efficient and produces extremely pure gold. It is commonly used by large refineries and is known for its ability to process large quantities of gold at once.

Steps Involved in Refining Gold

The process of refining gold involves several key steps. Each step is critical to ensure the gold reaches the desired level of purity. Below is an overview of the primary steps in gold refining.

Collecting and Preparing the Gold Material

The first step in the process is to collect the raw gold material. This could be gold ore from mining operations or recycled gold from old jewelry and electronics. The material is carefully inspected to determine its composition and the appropriate refining method.

Melting the Gold

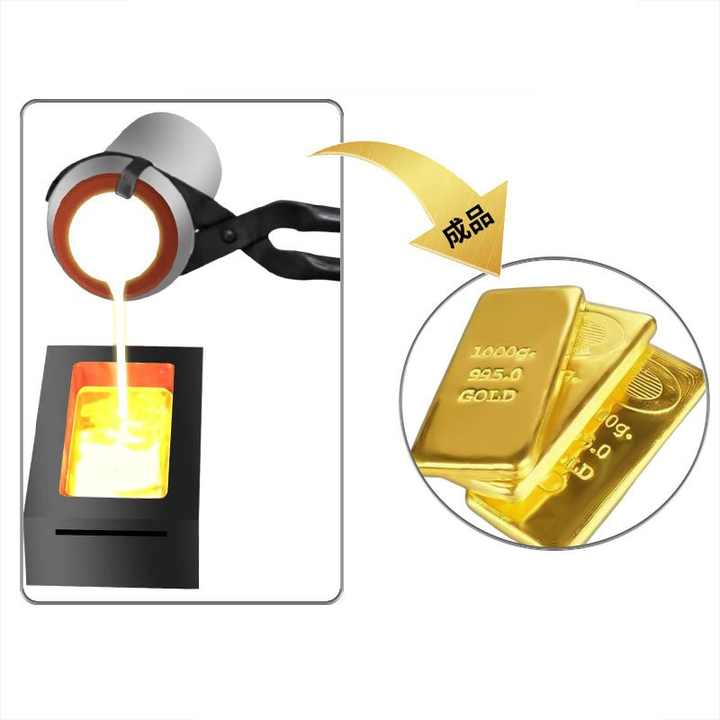

Once the material is prepared, it is melted in a furnace. High temperatures are used to liquefy the gold, allowing it to be separated from impurities. This step is crucial for eliminating many of the unwanted base metals that are present in the raw material.

Purification Process

After the gold is melted, the refining process continues with purification. Depending on the chosen refining method, chemical solutions or electrochemical processes are used to remove impurities and isolate pure gold. This stage ensures that the gold reaches the desired purity level, often between 99.5% and 99.9%.

Final Recovery of Pure Gold

Once the impurities are removed, the final step is to recover the pure gold. The gold is collected, washed, and dried to prepare it for further use. The resulting gold can be melted and cast into bars, coins, or other forms, depending on the needs of the refinery.

Benefits of Refining Gold

Refining gold is a critical process that ensures the production of high-purity gold for various industries, from jewelry to electronics. Below are some of the key benefits of refining gold.

Increased Purity

The primary goal of gold refining is to increase the purity of the gold. High-purity gold is essential for many applications, including investment, manufacturing, and electronics. The process of refining gold can increase the purity to 99.9%, ensuring that it meets the stringent standards required in these industries.

Recovery of Valuable Metals

Gold refining allows for the recovery of not only gold but also other valuable metals. During the refining process, metals such as silver, platinum, and palladium can be recovered and sold, making the process economically beneficial.

Environmental Benefits

Refining gold from recycled materials helps reduce the environmental impact of gold mining. By recycling old gold, refineries can minimize the need for new mining operations, which often have significant environmental consequences. This contributes to a more sustainable approach to gold production.

Safety and Environmental Considerations

While the process of refining gold is essential, it also requires careful handling of chemicals and equipment. Safety precautions must be taken to protect workers and the environment from harmful substances used in the refining process.

Handling Hazardous Chemicals

Many refining methods, such as aqua regia, involve the use of strong acids and chemicals. Proper safety gear, including gloves, goggles, and protective clothing, should be worn to prevent exposure to these substances. Refineries must also have appropriate ventilation systems in place to manage fumes.

Waste Management

The process of refining gold produces waste materials, including chemical residues and slag. Proper disposal of these materials is crucial to avoid environmental contamination. Refineries must follow local regulations for the disposal of hazardous waste to ensure they minimize their environmental impact.

Applications of Refined Gold

Refined gold is used in a wide range of applications due to its high purity and unique properties. Here are some of the most common uses of refined gold.

Jewelry and Ornaments

One of the most well-known applications of refined gold is in the production of jewelry and decorative ornaments. High-purity gold is highly sought after for its beauty and durability, making it a popular choice for rings, necklaces, and other fine jewelry.

Electronics and Technology

Refined gold is also widely used in the electronics industry due to its excellent conductivity and resistance to corrosion. Gold is used in the production of connectors, switches, and other components in devices like smartphones, computers, and televisions.

Investment and Currency

Gold bars and coins are a traditional form of investment and are often used as a hedge against economic instability. Refined gold is also held by central banks as part of their reserves, providing a store of value in times of financial uncertainty.

The process of refining gold is a complex and essential practice that ensures the production of high-purity gold for various industries. Whether through fire assaying, aqua regia, or electrolytic refining, this process is crucial for removing impurities and producing pure gold. With careful attention to safety and environmental considerations, gold refining contributes to a sustainable and economically viable approach to gold production.